Silk screening printing method

A technology of screen printing and screen printing, applied in printing, printing devices and other directions, can solve the problems of difficult bonding, difficult to obtain clear texture effect, inconvenient molding, etc., and achieve the effect of clear texture effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

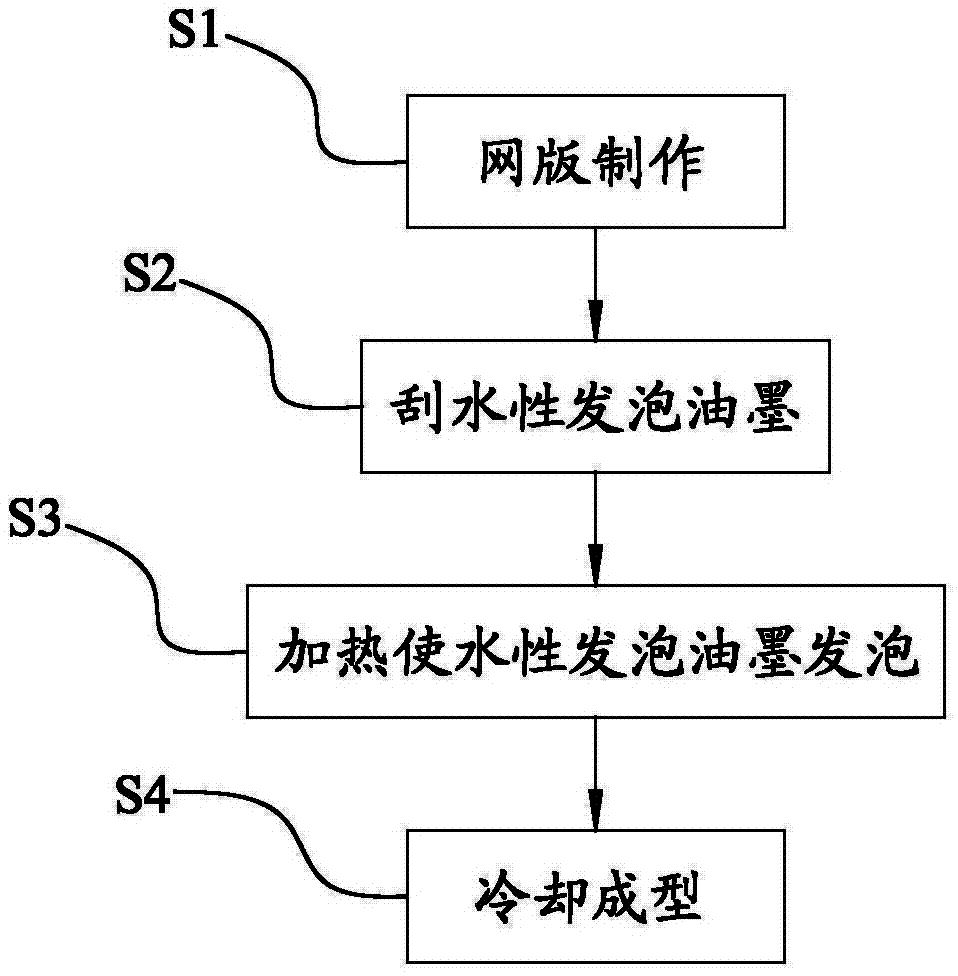

[0025] The flowchart of the embodiment of the present invention is as figure 1 shown. The screen printing method of the present embodiment comprises the following steps:

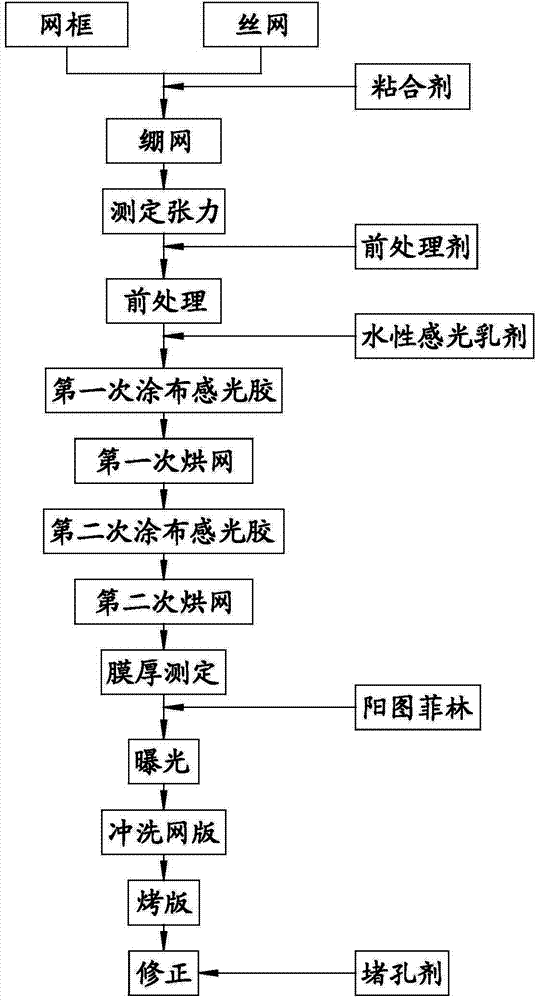

[0026] Step S1, making a screen plate by the direct plate-making method;

[0027] Step S2, using a screen printing machine scraper to print the water-based foaming ink from the hollow part of the screen onto the paper;

[0028] Step S3, sending the paper printed with the water-based foaming ink into a heating oven for heating to make the water-based foaming ink foam, wherein the heating oven is an infrared heating oven;

[0029] In step S4, the paper is taken out from the heating tunnel and then cooled and formed.

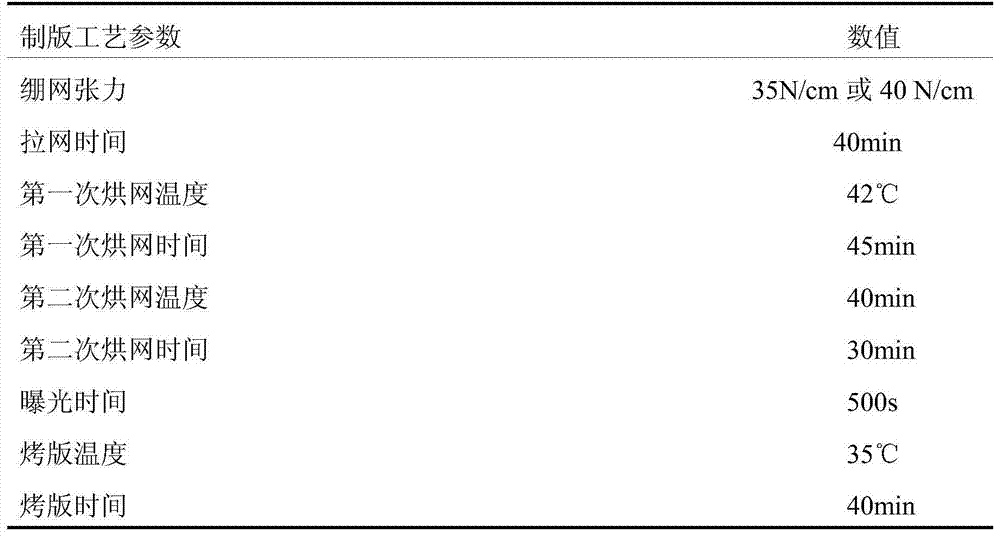

[0030] (1) Screen production

[0031] The screen making is step S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com