Preparation method of composite metal oxide modified titanium dioxide type solid acid and synthesis method of catalyzed polytetrahydrofuran ether

A technology of polytetrahydrofuran ether and solid acid catalyst, which is applied in the field of catalytic synthesis of polytetrahydrofuran ether, and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

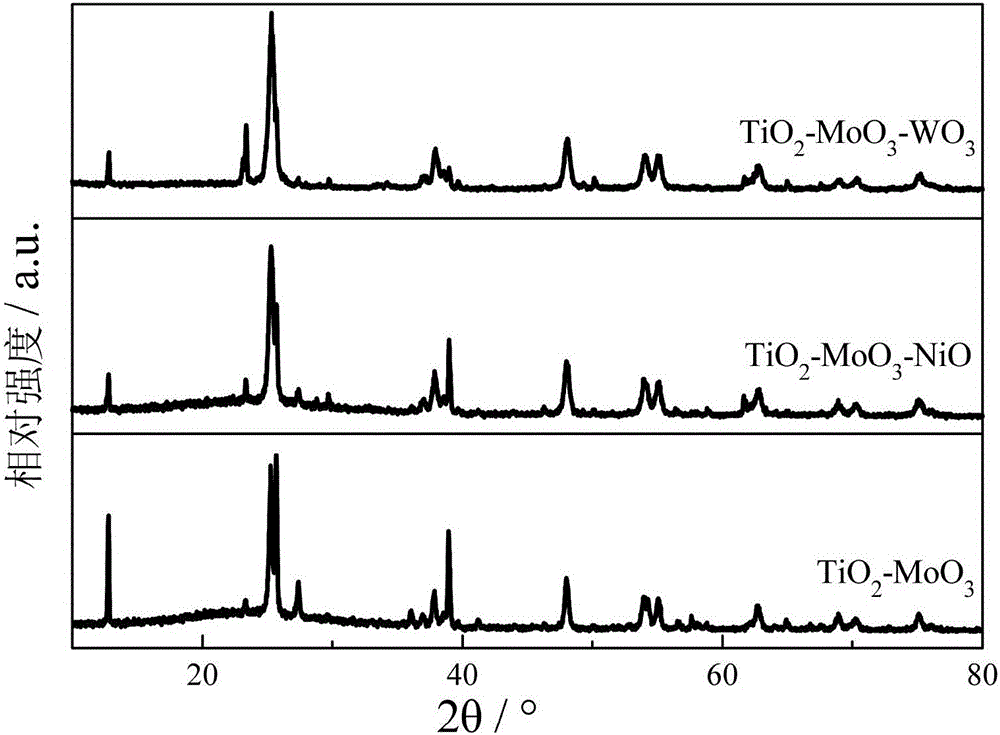

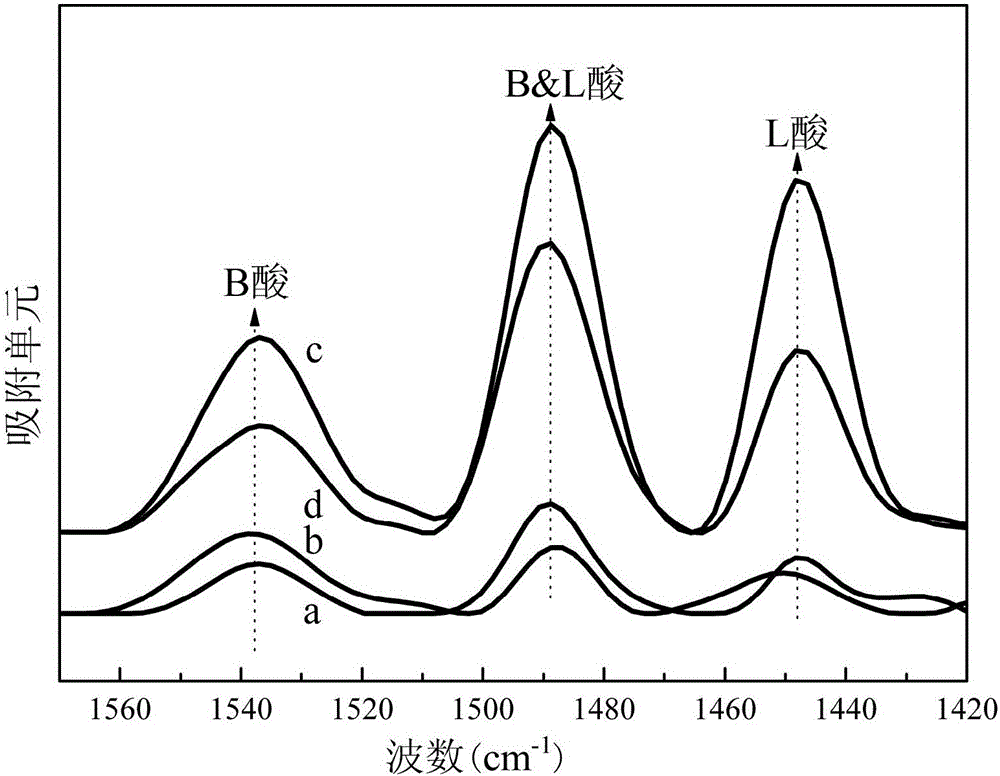

Embodiment 1

[0042] Dissolve titanium tetrachloride in deionized water, add ammonia water dropwise at 20°C, and adjust the pH to 9-11. Settled at 20°C for 20 hours and filtered under reduced pressure. The filter cake was washed with deionized water to contain no chloride ions, dried, and passed through a 200-mesh sieve to obtain white titanium hydroxide powder.

[0043] Dissolve 4g of ammonium molybdate in 20ml (1mol / L) of sulfuric acid, add 10g of titanium hydroxide, then add 0.35g of nickel sulfate, and stir for 4 hours. Heat and concentrate in a box-type resistance furnace until there is no liquid, and bake at 600°C for 3 hours to obtain a solid acid catalyst.

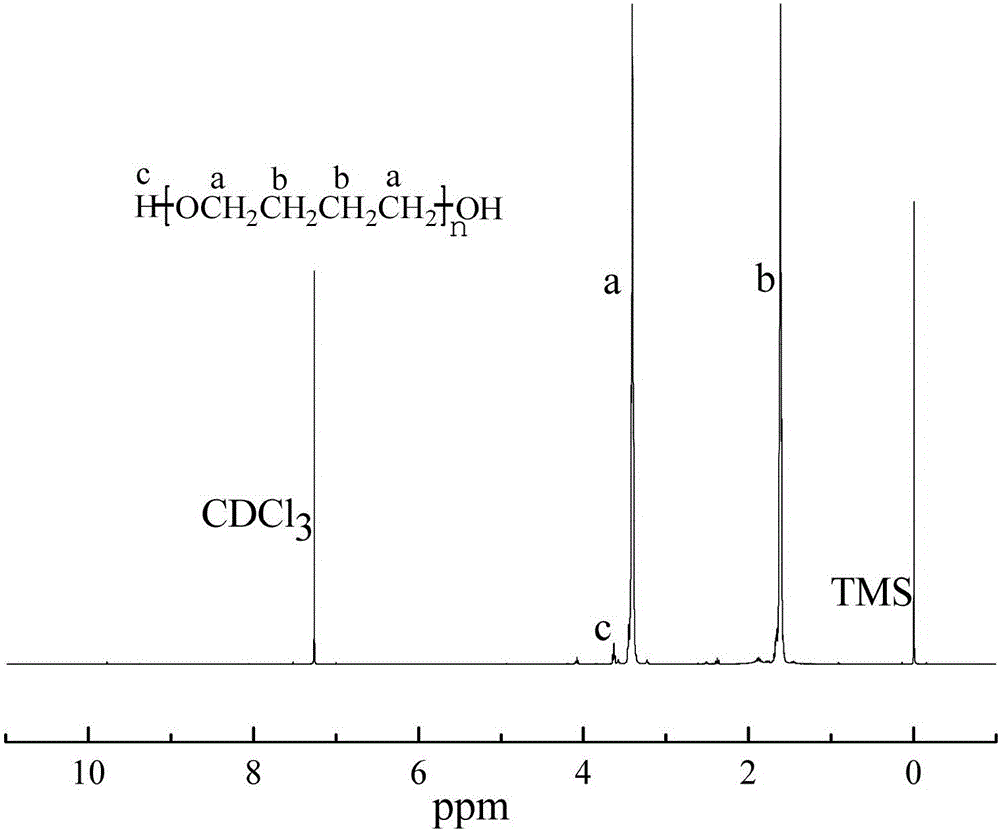

[0044]Tetrahydrofuran and solid acid catalyst were added into the flask according to the mass ratio of 10:1, and epichlorohydrin was added according to 0.1% of the mass of tetrahydrofuran. The temperature was controlled at 10°C for 48 hours. Add 30ml of toluene to the product, filter, and distill the toluene from the filtrate...

Embodiment 2

[0048] Dissolve 4g of ammonium molybdate in 20ml (1mol / L) of sulfuric acid, add 10g of titanium hydroxide, then add 0.76g of sodium tungstate, and stir for 4 hours. Heat and concentrate in a box-type resistance furnace until there is no liquid, and bake at 550°C for 3 hours to obtain a solid acid catalyst.

[0049] Tetrahydrofuran and solid acid catalyst were added into the flask according to the mass ratio of 10:1, and epichlorohydrin was added according to 0.1% of the mass of tetrahydrofuran. The temperature was controlled at 10°C for 48 hours. The product was filtered and the yield was 72.6%.

Embodiment 3

[0051] Dissolve 4g of ammonium molybdate in 20ml (1mol / L) of sulfuric acid, add 10g of titanium hydroxide, then add 0.18g of nickel sulfate, 0.38g of sodium tungstate, and stir for 4 hours. Heat and concentrate in a box-type resistance furnace until there is no liquid, and bake at 600°C for 3 hours to obtain a solid acid catalyst.

[0052] Tetrahydrofuran and solid acid catalyst were added into the flask according to the mass ratio of 10:1, and epichlorohydrin was added according to 0.1% of the mass of tetrahydrofuran. The temperature was controlled at 15°C for 36 hours. Add 30ml of toluene to the product, filter, and distill the toluene from the filtrate to obtain polytetrahydrofuran ether. The yield was 74.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com