Preparation method of complex metal oxide modified titanium dioxide type solid acid and catalytic synthesis method of polytetrahydrofuran ether using same

A technology of polytetrahydrofuran ether and solid acid catalyst, which is applied in the field of catalytic synthesis of polytetrahydrofuran ether, can solve the problems of high cost and achieve the effects of high space-time efficiency, short time and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

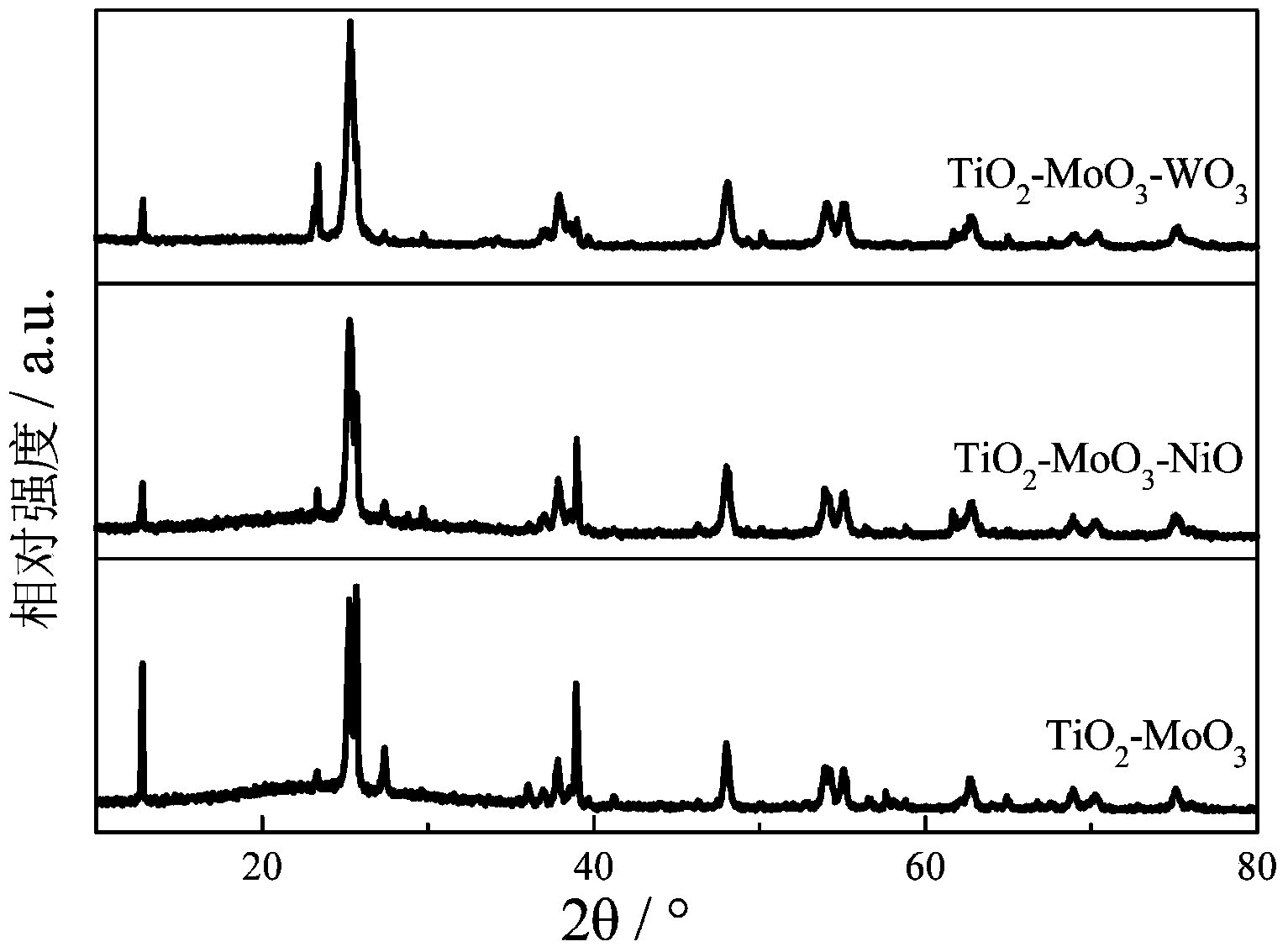

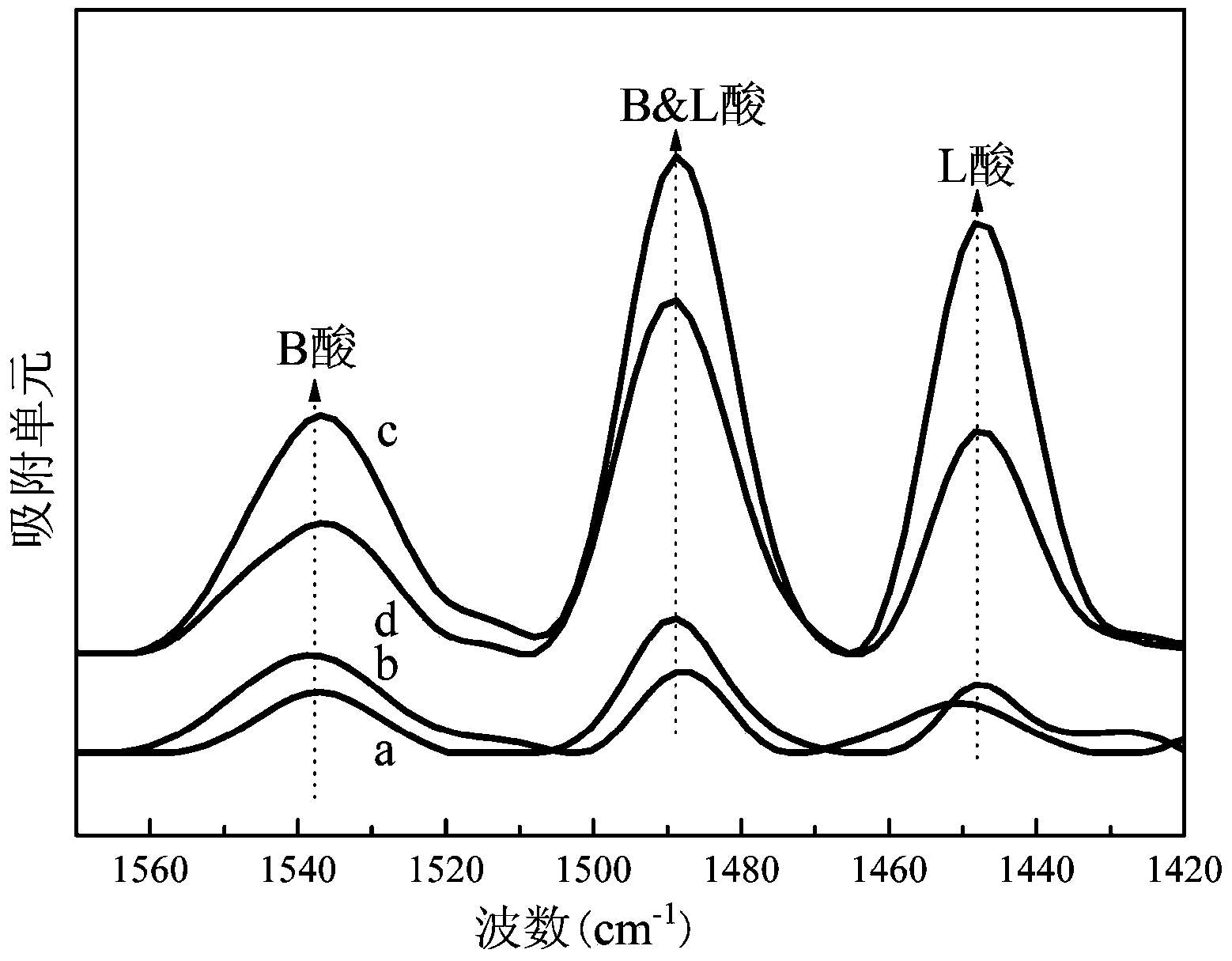

[0042] Dissolve titanium tetrachloride in deionized water, add ammonia water dropwise at 20°C, and adjust the pH to 9-11. Settled at 20°C for 20 hours and filtered under reduced pressure. The filter cake was washed with deionized water to contain no chloride ions, dried, and passed through a 200-mesh sieve to obtain white titanium hydroxide powder.

[0043] Dissolve 4g of ammonium molybdate in 20ml (1mol / L) of sulfuric acid, add 10g of titanium hydroxide, then add 0.35g of nickel sulfate, and stir for 4 hours. Heat and concentrate in a box-type resistance furnace until there is no liquid, and bake at 600°C for 3 hours to obtain a solid acid catalyst.

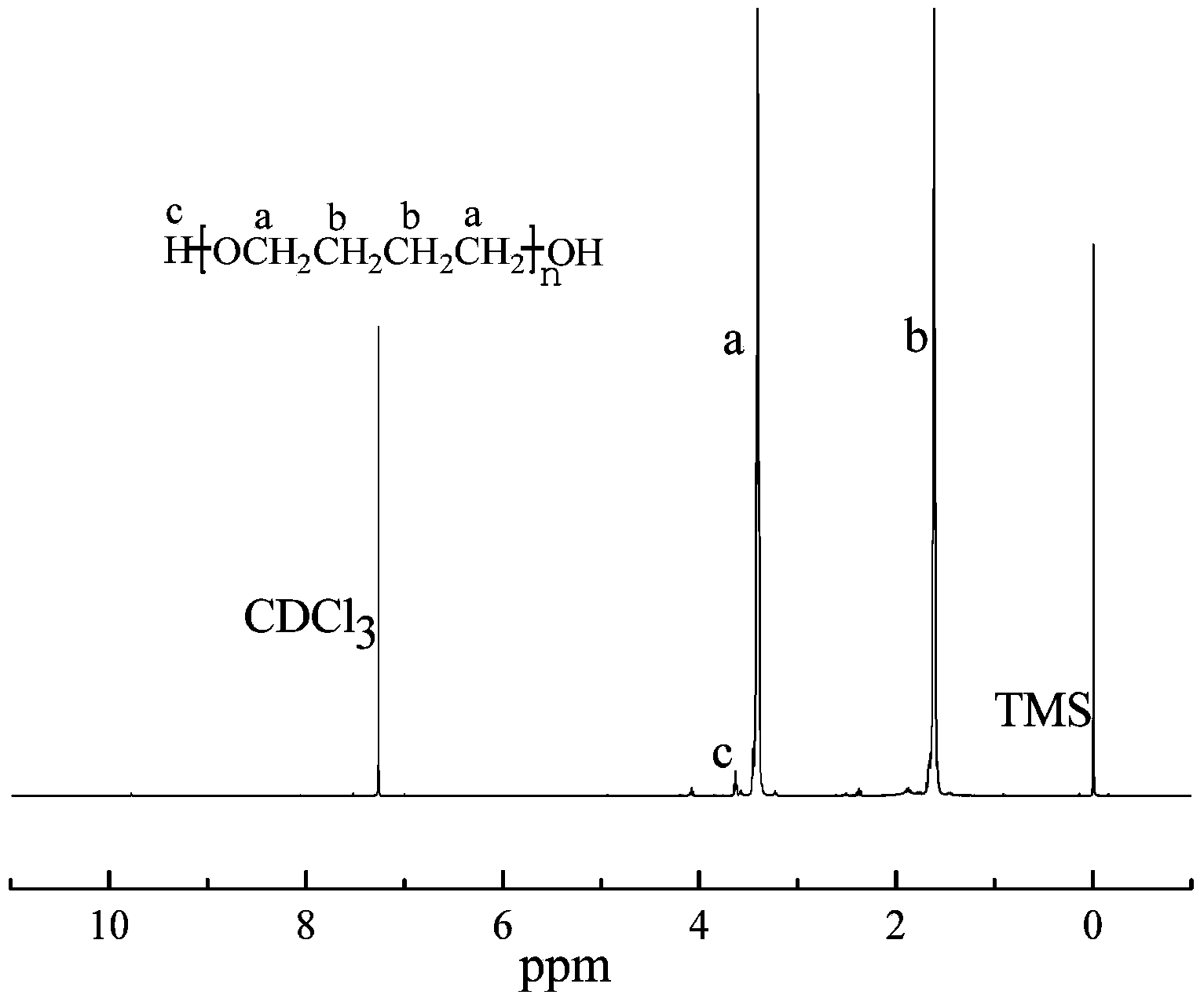

[0044] Tetrahydrofuran and solid acid catalyst were added into the flask according to the mass ratio of 10:1, and epichlorohydrin was added according to 0.1% of the mass of tetrahydrofuran. The temperature was controlled at 10°C for 48 hours. Add 30ml of toluene to the product, filter, and distill the toluene from the filtrate ...

Embodiment 2

[0048] Dissolve 4g of ammonium molybdate in 20ml (1mol / L) of sulfuric acid, add 10g of titanium hydroxide, then add 0.76g of sodium tungstate, and stir for 4 hours. Heat and concentrate in a box-type resistance furnace until there is no liquid, and bake at 550°C for 3 hours to obtain a solid acid catalyst.

[0049] Tetrahydrofuran and solid acid catalyst were added into the flask according to the mass ratio of 10:1, and epichlorohydrin was added according to 0.1% of the mass of tetrahydrofuran. The temperature was controlled at 10°C for 48 hours. The product was filtered and the yield was 72.6%.

Embodiment 3

[0051] Dissolve 4g of ammonium molybdate in 20ml (1mol / L) of sulfuric acid, add 10g of titanium hydroxide, then add 0.18g of nickel sulfate, 0.38g of sodium tungstate, and stir for 4 hours. Heat and concentrate in a box-type resistance furnace until there is no liquid, and bake at 600°C for 3 hours to obtain a solid acid catalyst.

[0052] Tetrahydrofuran and solid acid catalyst were added into the flask according to the mass ratio of 10:1, and epichlorohydrin was added according to 0.1% of the mass of tetrahydrofuran. The temperature was controlled at 15°C for 36 hours. Add 30ml of toluene to the product, filter, and distill the toluene from the filtrate to obtain polytetrahydrofuran ether. The yield was 74.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com