Electrically controlled opening and closing fuel filler cap

A fuel filler cap, electric technology, applied in the superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve the problems that the fuel filler cap cannot be automatically closed and locked, cannot realize electric automation, and has no error-proof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

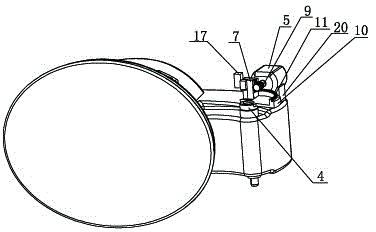

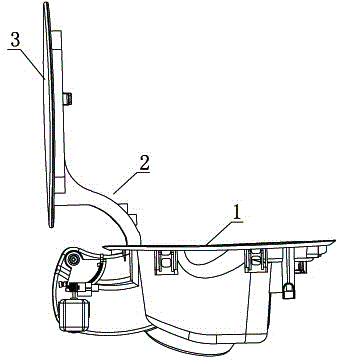

[0036]This embodiment is an electrically controlled opening and closing fuel filler cap, refer to figure 1 , figure 2 , Figure 4 — Figure 7 , which includes a fuel filler cap pipe 1, a hinge arm 2, a cover plate 3, a fuel filler cap body 4, and an electric opening and closing device for opening and closing the fuel filler cap body 4 controlled by the vehicle ECU. The working end of the device is linked with the fuel filler cap body 4 . Specifically:

[0037] The electric opening and closing device includes a driven rotating member that is integrally connected with the fuel filler cap body 4 and can rotate coaxially and synchronously. fuel filler cap switch 6. Fuel filler cap switch 6 corresponds to the corresponding position ahead of the driver's seat on the car body, such as instrument panel panel, left front door guard plate, and can also be fixed in other places that are convenient for the driver to operate.

[0038] The output shaft of the motor 5 is fixedly conne...

Embodiment 2

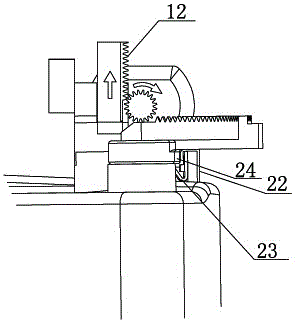

[0062] This embodiment is an electrically controlled opening and closing fuel filler cap, which differs from Embodiment 1 in that:

[0063] The cross-sectional structure of the side where the closing action limiting device 7 is close to the card arm 18 is a "7" shape with a right angle at the corner (used to replace the one in the closing action limiting device 7 and the card arm 18 that is close to the locking arm 18 in Embodiment 1). "]"-shaped limit groove on one side).

[0064] The structure of other parts of this embodiment is exactly the same as that of Embodiment 1.

Embodiment 3

[0066] This embodiment is an electrically controlled opening and closing fuel filler cap, which differs from Embodiment 1 in that:

[0067] The closing action limiting device 7 is knife-shaped, that is, it includes an upper toothed strip part and a lower single-leg part. The arc-shaped edge of the chainring 10 can be located below the strip-shaped part and the radius is smaller than the radius of the single-leg. Rotate in the area. (That is: the chainring 10 no longer has the arc-shaped extension end 13; the single leg replaces the two legs of embodiment 1)

[0068] The structure of other parts of this embodiment is exactly the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com