Mobile terminal circuit board assembly and mobile terminal

A circuit board assembly, mobile terminal technology, applied in electrical components, color TV parts, TV system parts and other directions, can solve the problems of poor contact, hindered signal transmission, high cost of flexible circuit boards and connectors, and achieve Ensure reliable contact, save manufacturing costs, and ensure reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

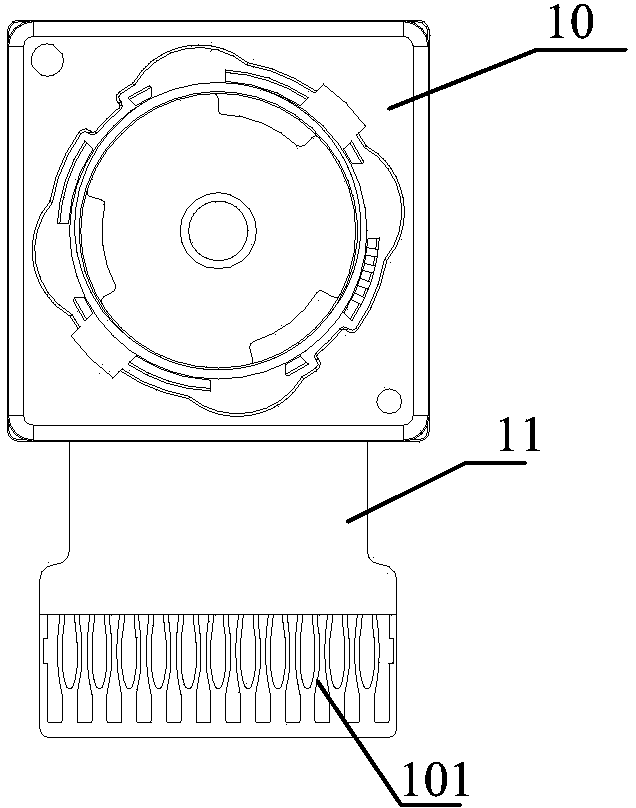

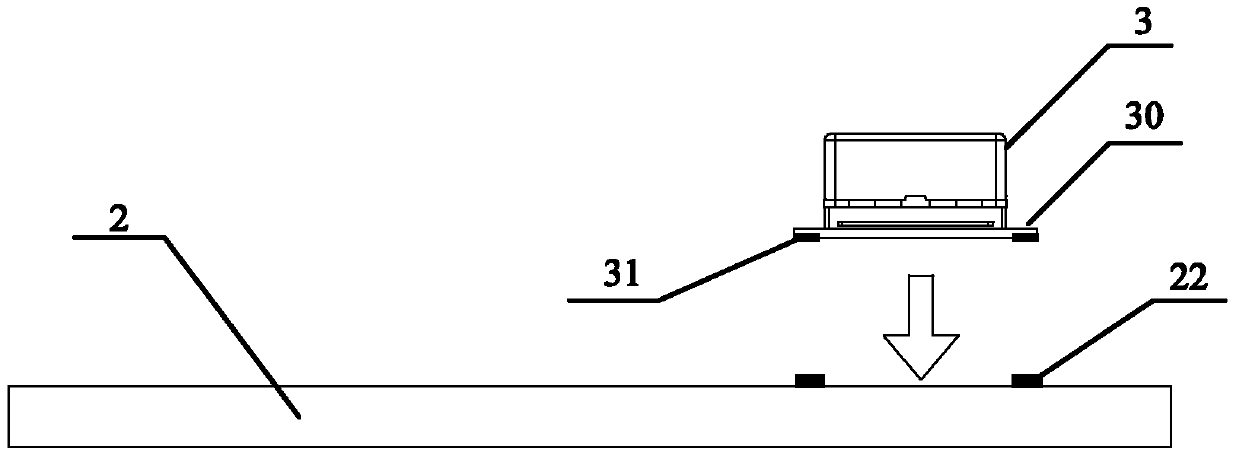

[0027] figure 2 It is a schematic diagram of an exploded structure of an embodiment of the mobile terminal circuit board assembly of the present invention; image 3 for figure 2 A top view of the camera module in ; please refer to figure 2 with image 3 , the present embodiment provides a mobile terminal circuit board assembly, including a main circuit board 2 and a camera module 3 for collecting image information, the camera module 3 includes a substrate 30, and the substrate 30 is a printed circuit board (PCB) And be arranged in parallel above or below the main circuit board 2; a first conductive connection part 31 is formed around the substrate 30, and a second conductive connection part 22 is provided on the surface of the main circuit board 2, and the second conductive connection part 22 is connected to the first conductive connection part 22. The connecting parts 31 are fixedly connected in one-to-one correspondence, so as to fix the substrate 30 on the main circui...

Embodiment 2

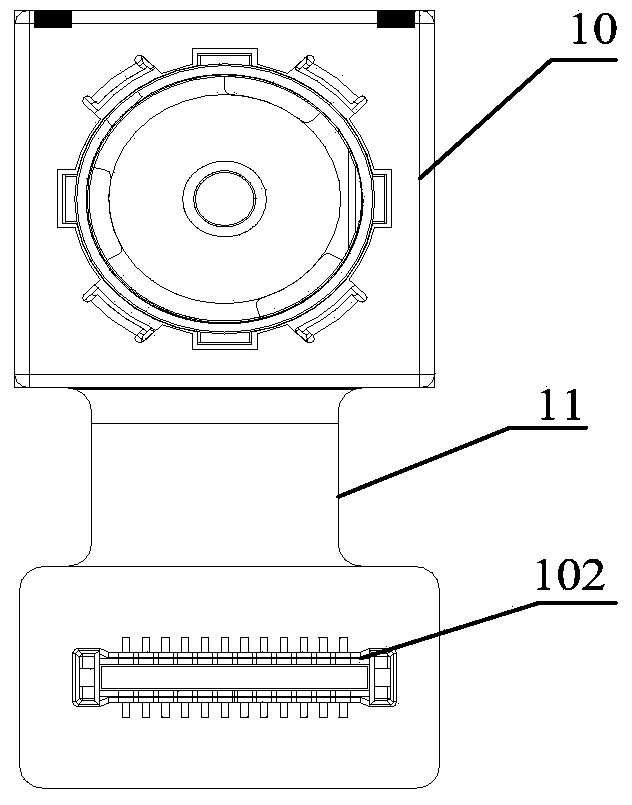

[0034] Figure 4 It is a structural schematic diagram of another embodiment of the mobile terminal circuit board assembly of the present invention; Figure 5 for Figure 4 The top view of the camera module in ; the difference between this embodiment and the first embodiment is that the first conductive connection part and the second conductive connection part are mechanically fixedly connected. Such as Figure 4 with Figure 5 As shown, the mobile terminal circuit board assembly of this embodiment can also include a camera module 3 and a main circuit board 2, wherein the camera module 3 is arranged above the main circuit board 2; the first conductive connection part 31 is formed on the substrate 30 A plurality of conductive contacts 312 on the edge of the top surface are insulated between adjacent conductive contacts 312; the second conductive connector is a plurality of claw terminals 221 arranged on the top surface of the main circuit board 2, and the claw terminals 221 ...

Embodiment 3

[0042] Image 6 A schematic structural diagram of another embodiment of the mobile terminal circuit board assembly of the present invention; Figure 7 for Image 6 The top view of the middle camera module; the difference between this embodiment and the first embodiment is that the substrate 30 is arranged under the main circuit board 2 .

[0043] Such as Image 6 with Figure 7 As shown, this embodiment provides a mobile terminal circuit board assembly, including a main circuit board 2 and a camera module 3. The camera module 3 includes a base plate 30 and a lens that is fixedly arranged on the top surface of the base plate 30 and houses a lens inside. Lens module 32. The first conductive connection part 31 is a plurality of conductive first pads 311 formed around the substrate 30. Correspondingly, the top or bottom surface of the main circuit board 2 can form a second pad corresponding to the position of the first conductive connection part 31. The substrate 30 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com