Wiper cassette, wiper unit and liquid ejecting apparatus

一种液体喷射头、擦拭器的技术,应用在印刷等方向,能够解决无法容易盒装卸更换等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

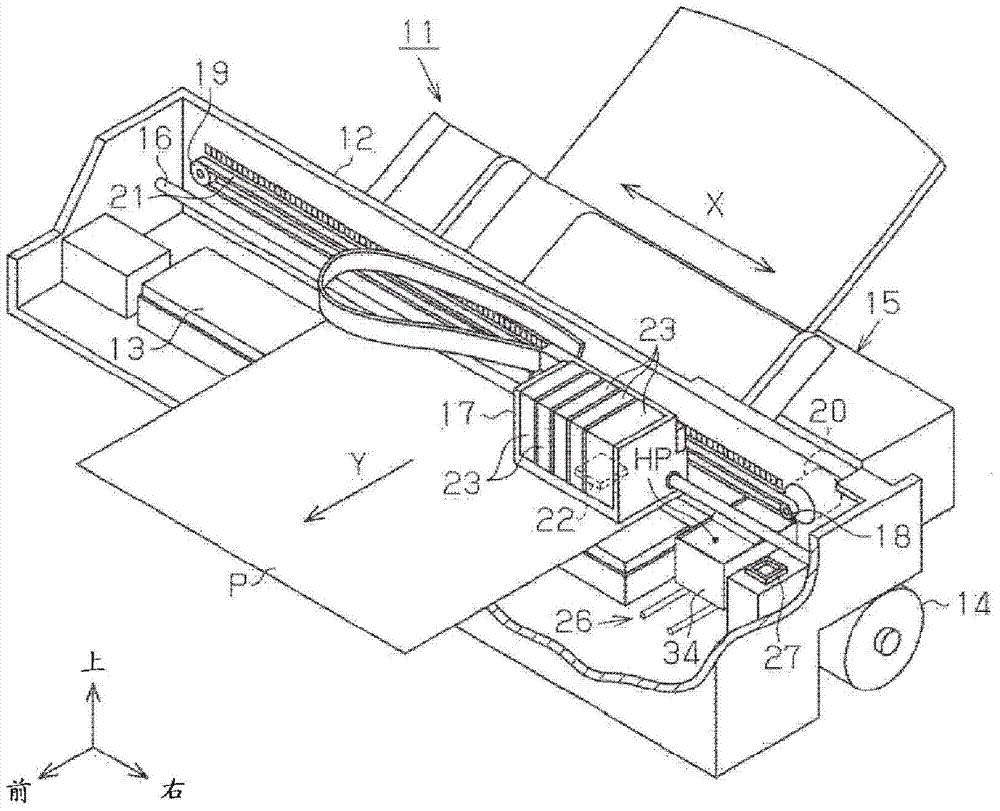

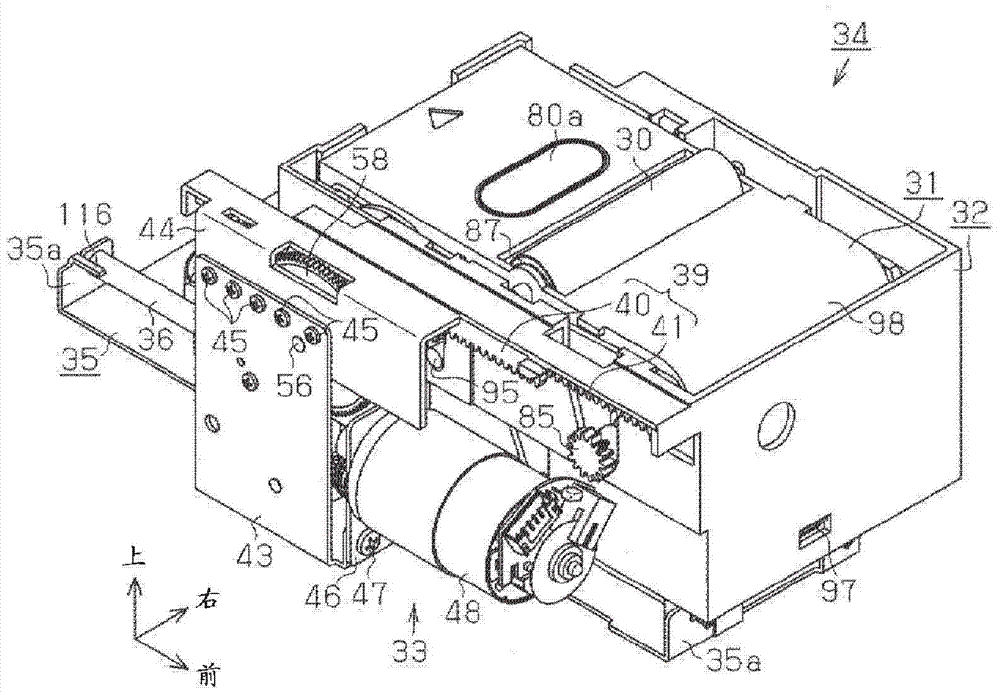

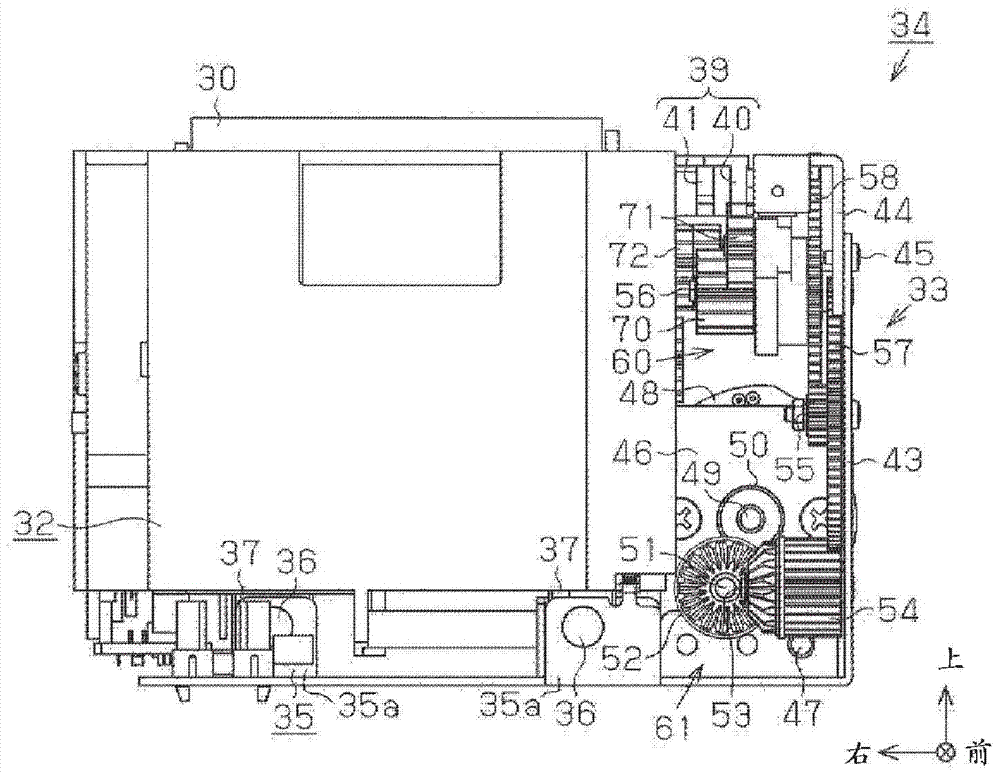

[0047] Hereinafter, an embodiment in which a wiper unit including a wiper cartridge is attached to an inkjet printer that is a type of liquid ejecting apparatus will be described with reference to the drawings.

[0048] Such as figure 1 As shown, in the printer 11, in the inner lower part of the frame 12 formed in an approximately rectangular box shape, the long side direction is aligned with the main scanning direction X( figure 1 Center is the state of left-right direction) and is provided with the supporting member 13 that is formed in the substantially rectangular plate shape. On this support member 13, based on the drive of the paper feed motor 14 provided at the rear lower part of the frame 12, the main scanning direction X is perpendicular to the sub-scanning direction Y ( figure 1 The recording paper P is conveyed on the rear side of the front-to-back direction in the middle. In addition, above the support member 13 in the frame 12 , a rod-shaped guide shaft 16 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com