Method and apparatus for inspecting workpieces

一种工件、设备的技术,应用在坐标测量设备领域,能够解决难以确立、耗费时间、未知的等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

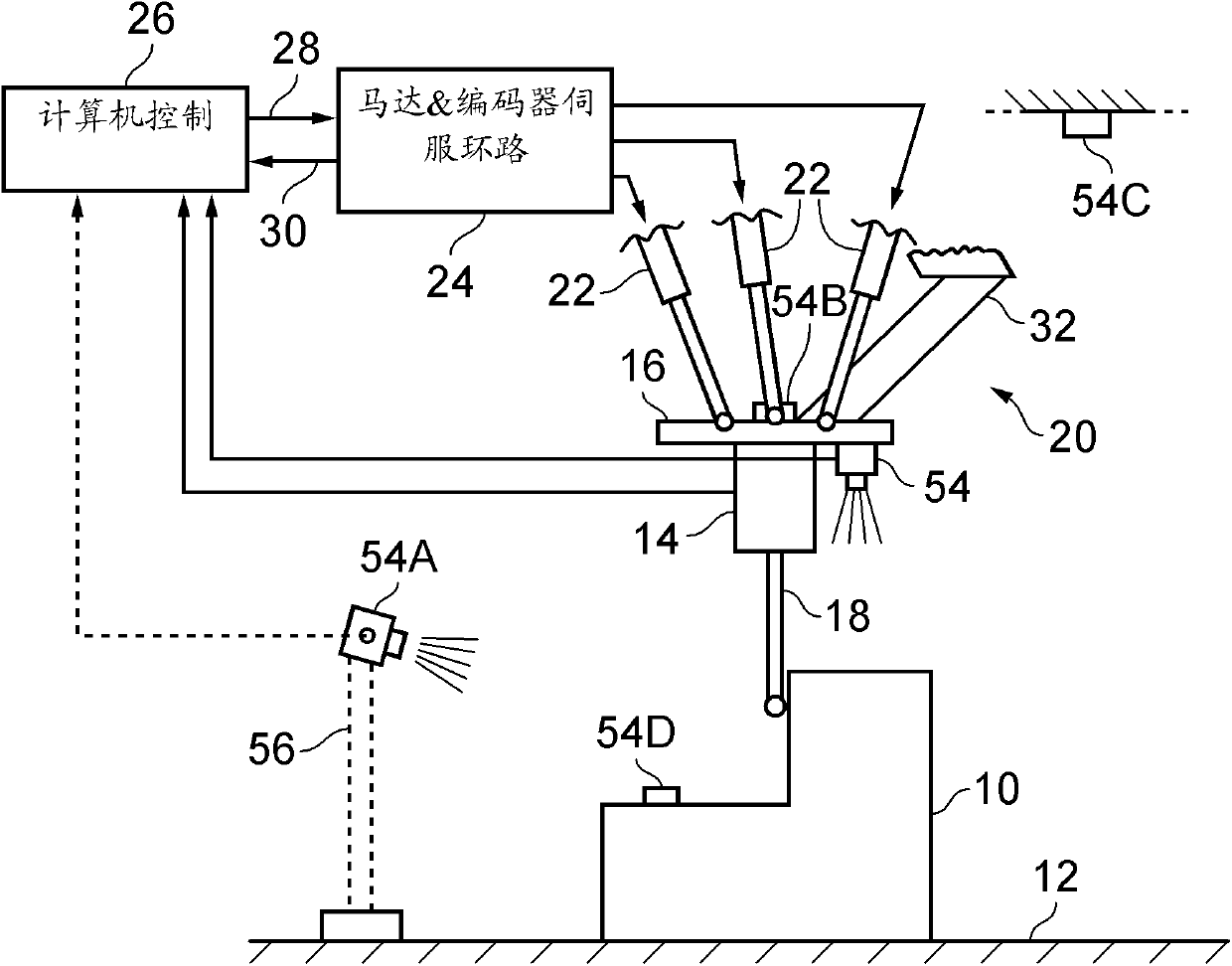

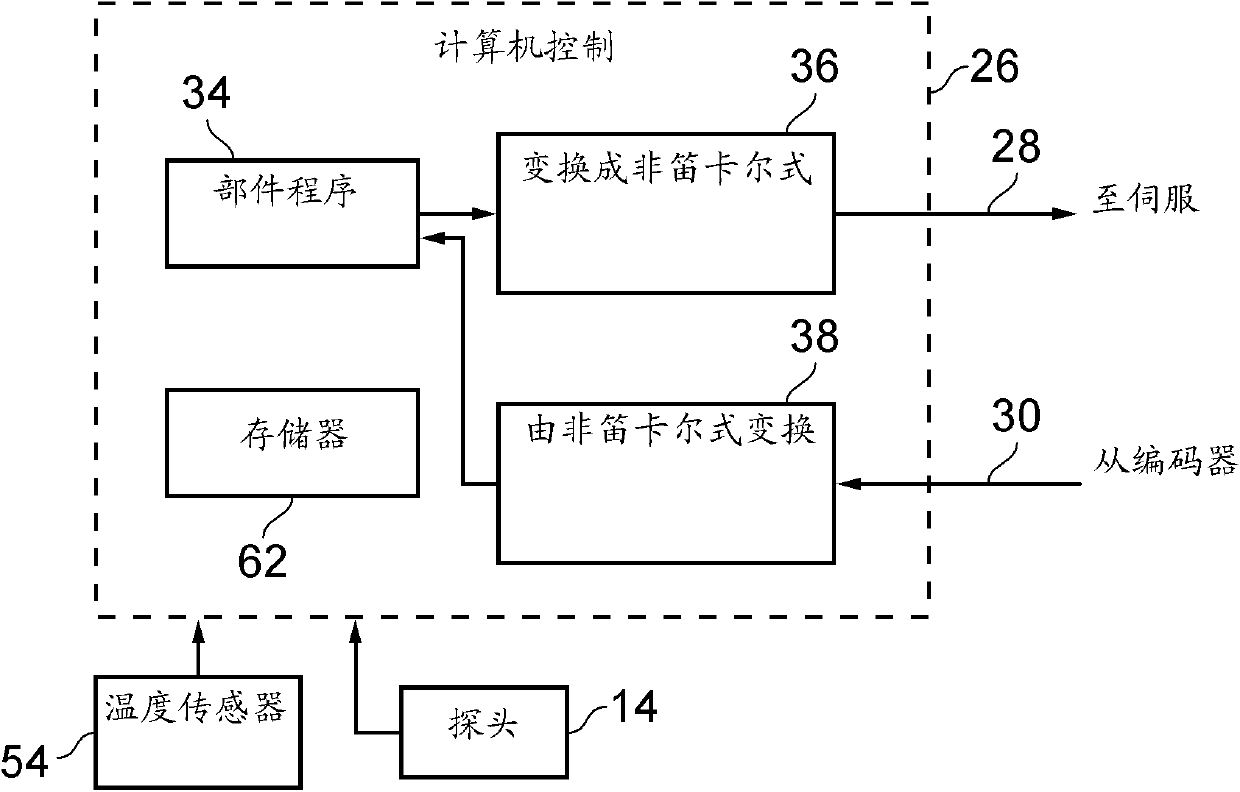

[0049] exist figure 1 In the coordinate measuring machine shown, a workpiece 10 to be measured is placed on a table 12 which forms part of the fixed structure of the machine. A probe having a body 14 is mounted to a movable platform member 16 . The probe has a displaceable elongated stylus 18 which, in use, contacts the workpiece 10 for metrology measurements.

[0050] The movable platform member 16 is secured to a fixed structure of the machine by a support mechanism 20 (only a portion of which is shown). In this embodiment, the supporting mechanism 20 is as described in International Patent Applications WO03 / 006837 and WO2004 / 063579. It comprises 3 telescopically extendable struts 22 extending in parallel between the platform 16 and the fixed structure of the machine. Each end of each strut 22 is all pivotally connected to the platform 16 or the fixed structure respectively, and is extended and retracted by a respective motor. The amount of extension is measured by the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com