Brushless direct current motor having sfoc control

A technology of DC motors and adjustment devices, which is applied in electronic commutation motor control, electrical components, electronic commutators, etc., and can solve problems such as technical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

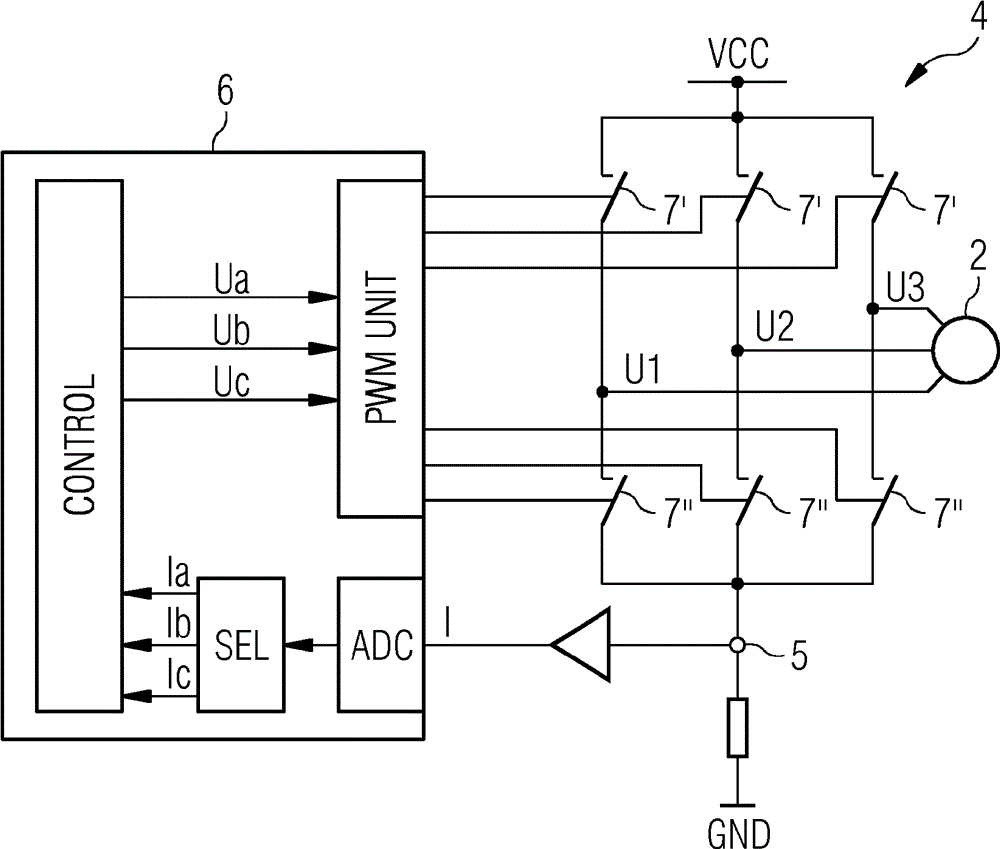

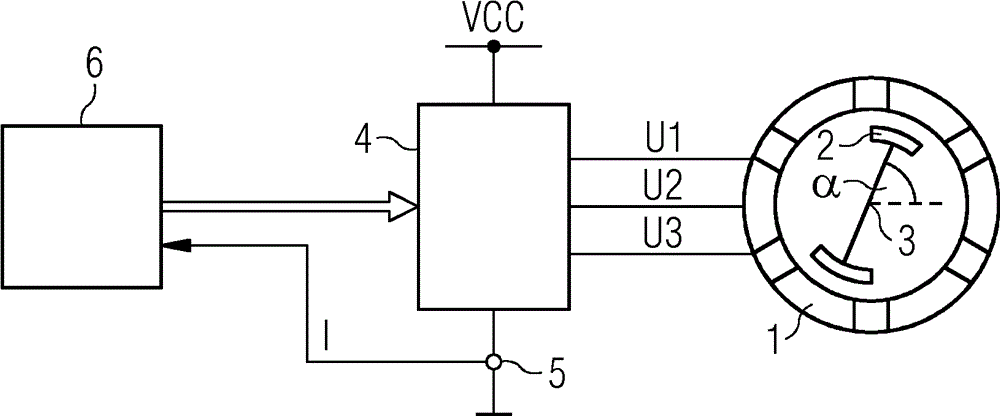

[0039] according to figure 1 , a brushless DC motor has a stator 1 and a rotor 2. The rotor 2 is mounted rotatably about an axis of rotation 3 relative to the stator 1 .

[0040] The DC motor also has an adjustment device 4 . The phases U1 , U2 , U3 of the DC motor can be switched to the supply voltage VCC by means of the regulating device 4 . A single current detection device 5 is arranged downstream of the adjustment device 4 .

[0041] The DC motor also has a control device 6 . In particular, the control device 6 can be designed as a programmable or permanently wired control device 6 . The control device 6 is connected to the adjustment device 4 so that the control device 6 can actuate the adjustment device 4 . The control device 6 is also connected to the current detection device 5 so that the control device 6 can receive the total current I respectively detected by the current detection device 5 . The control device 6 is programmed or configured in such a way that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com