Schrader valve and Presta valve dual-purpose tuyere head

A dual-purpose air nozzle head and French nozzle technology, which is applied in the direction of control valves, function valve types, engine components, etc., can solve pressure relief, users cannot choose operation modes, hoses cannot be compatible with external pumps or high-pressure gas cylinders, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

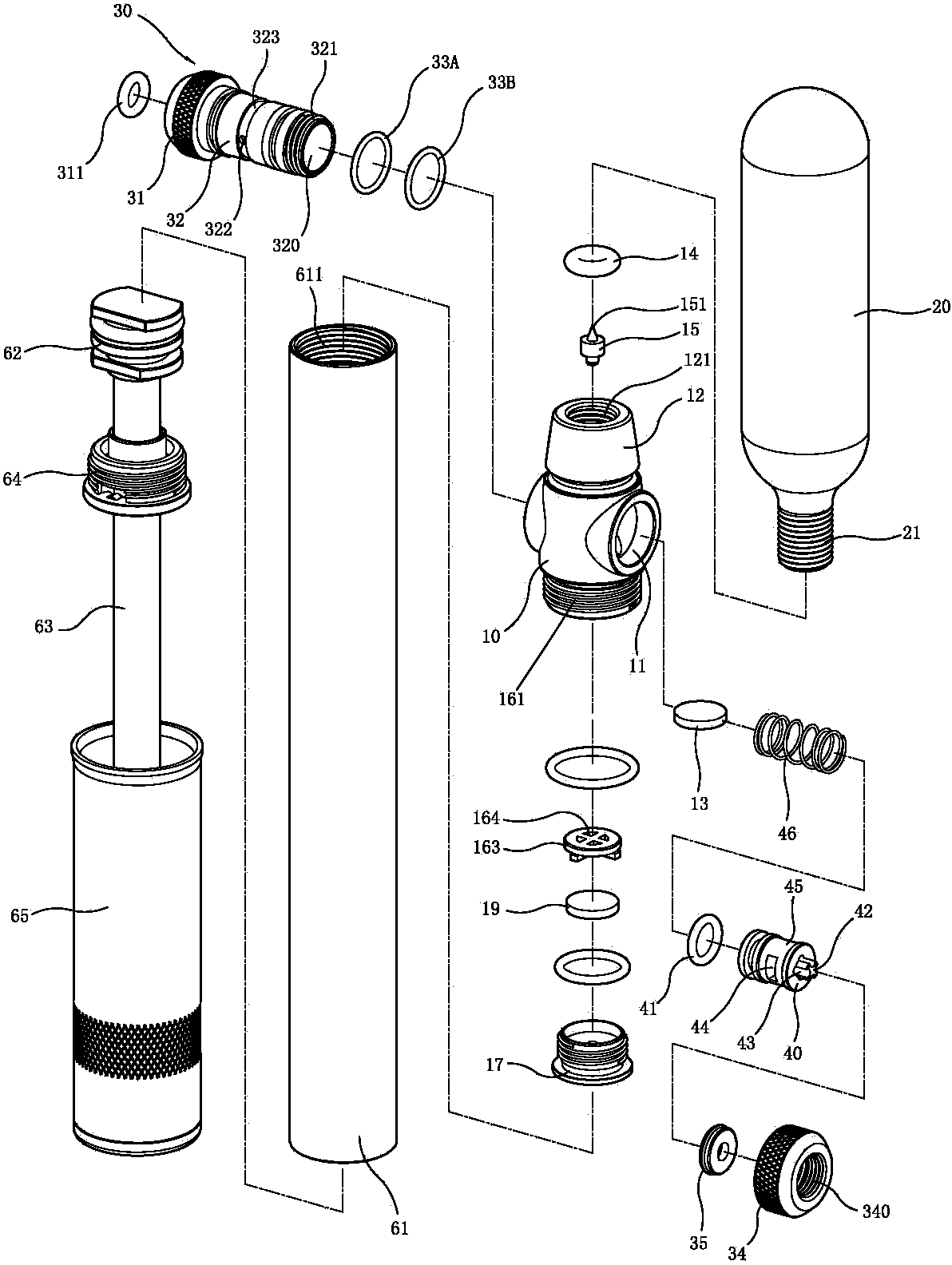

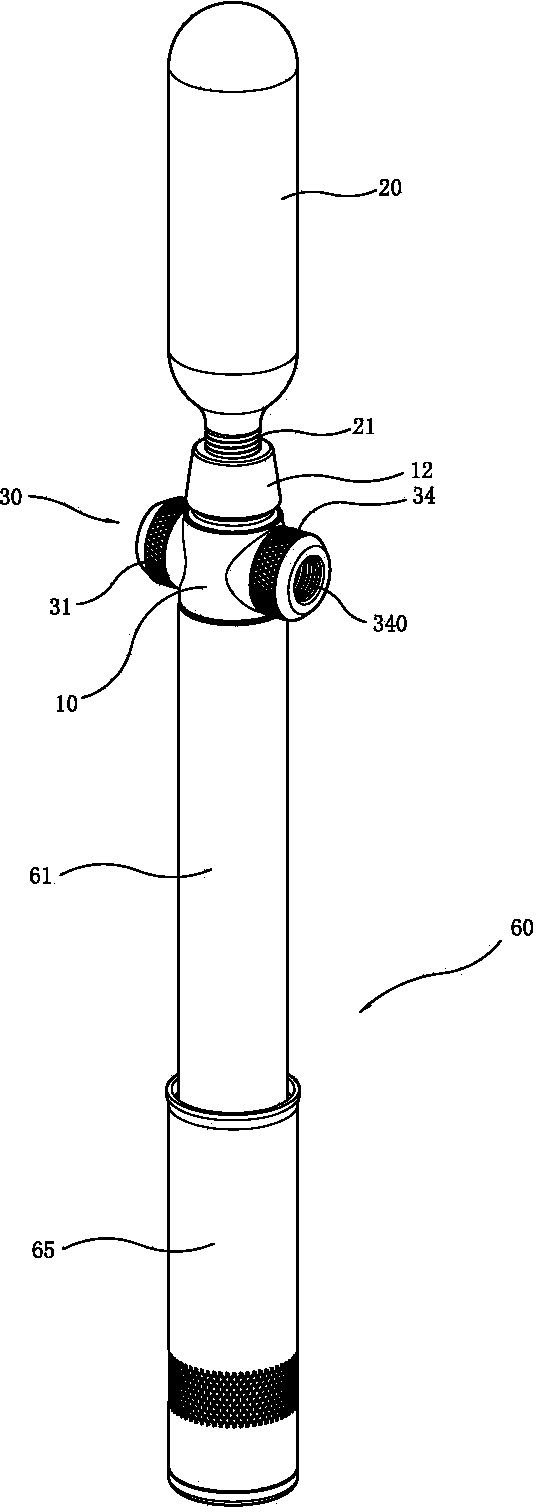

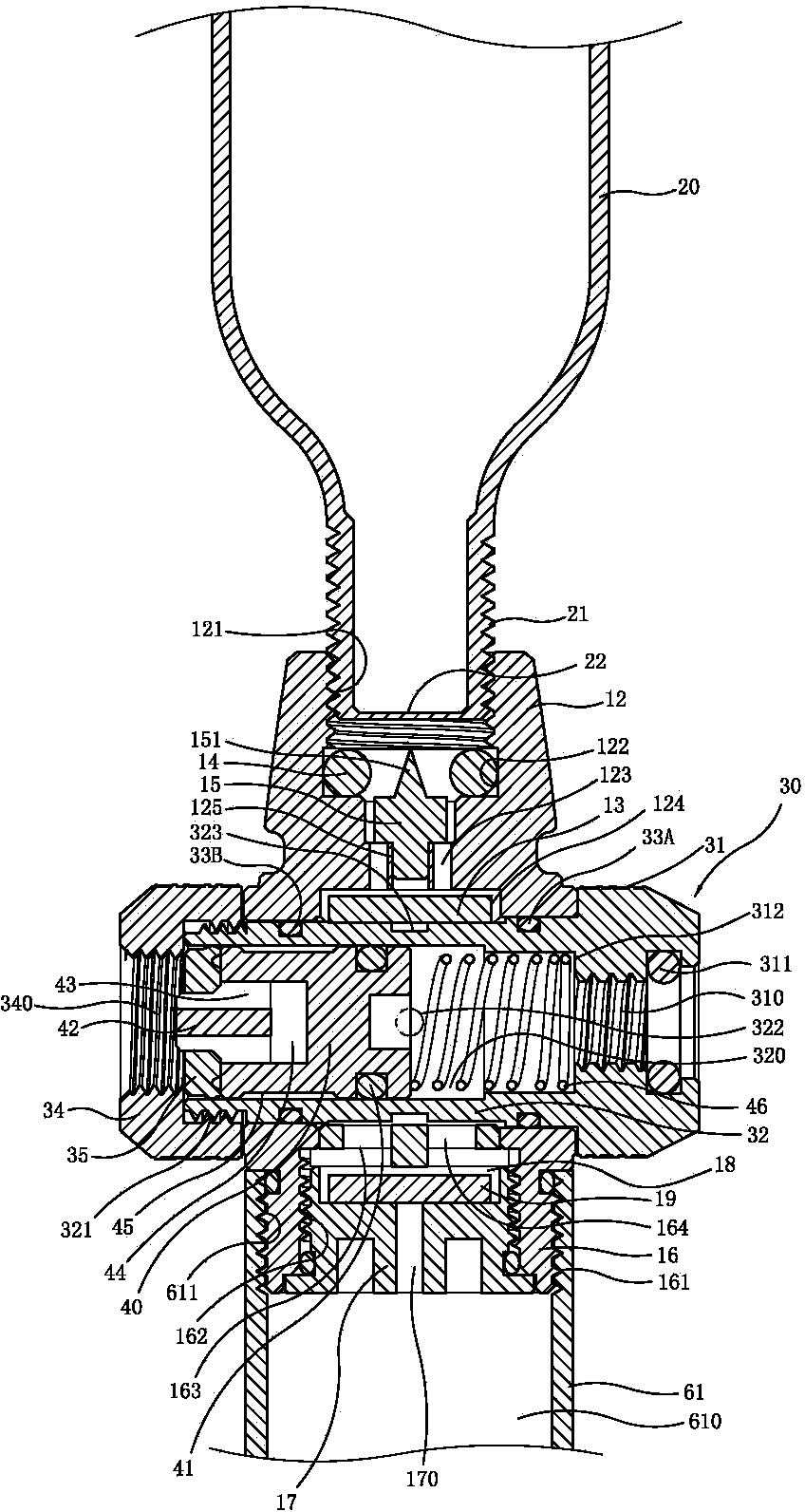

[0047] Please see figure 1 , figure 2 ,image 3 , the present invention includes:

[0048] A housing 10, which has a shaft hole 11 that runs through the left and right ends, and a first assembly portion 12 extending on the outer circumference for the installation of the first pumping device 20, the first assembly portion 12 has a recessed Threaded segment 121, the bottom end of this threaded segment 121 communicates with an annular hole 122, and the housing 10 is further provided with a first air supply hole 123 that can communicate with the shaft hole 11 at the bottom end of the annular hole 122, and the first air supply hole 123 and the shaft A first non-return chamber 124 is further formed at the junction of the hole 11. The first non-return chamber 124 is recessed on the wall of the shaft hole 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com