Positive temperature coefficient thermistor for car heater and manufacturing method thereof

A technology of positive temperature coefficient and thermistor, applied in the direction of resistors with positive temperature coefficient, etc., can solve the problems of immature high reliability technology and achieve the effect of high life and stable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

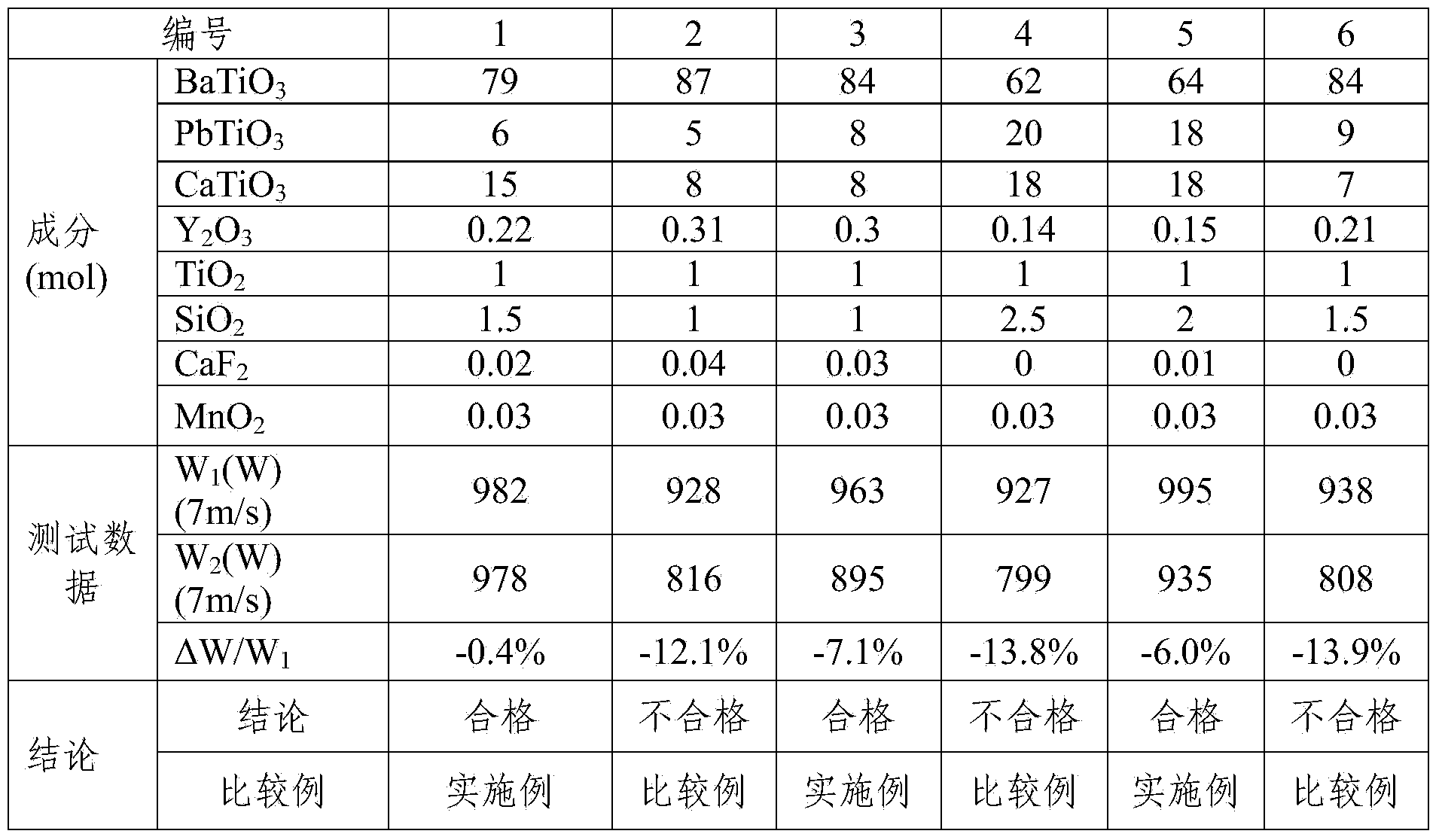

[0012] The invention provides a positive temperature coefficient thermistor method for an automobile heater, wherein each component and its mole percentage content are respectively: BaTiO 3 : 64%~84%, PbTiO 3 : 6%~18%, CaTiO 3 : 8%~18%, Y 2 o 3 : 0.15%~0.3%, SiO 2 : 1%~2%, CaF 2 : 0.01%~0.03%, TiO 2 : 1% and MnO 2 : 0.03%. The additive CaF 2 By replacing the O element with F, the diversity of semiconducting substitution positions is increased, thereby improving the stability of the product.

[0013] The invention provides a method for manufacturing a positive temperature coefficient thermistor for an automobile heater, comprising the following steps:

[0014] Step 1: BaTiO with a molar percentage of 64%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com