Adapter assembling module

A riser card and module technology, applied in the direction of circuit devices, support structure installation, instruments, etc., can solve problems such as difficult to pull out the riser card, easy to damage the golden finger of the riser card slot, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

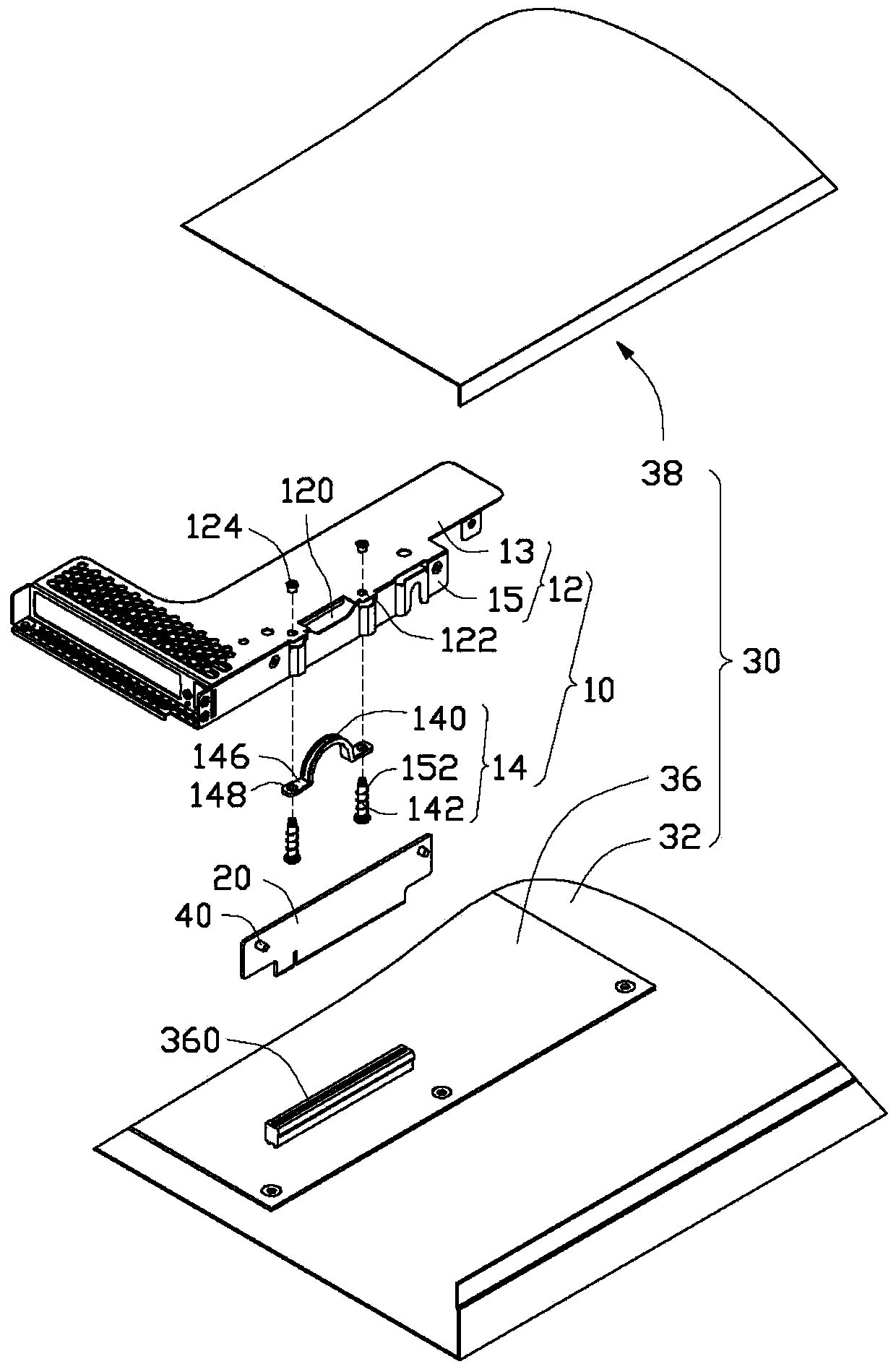

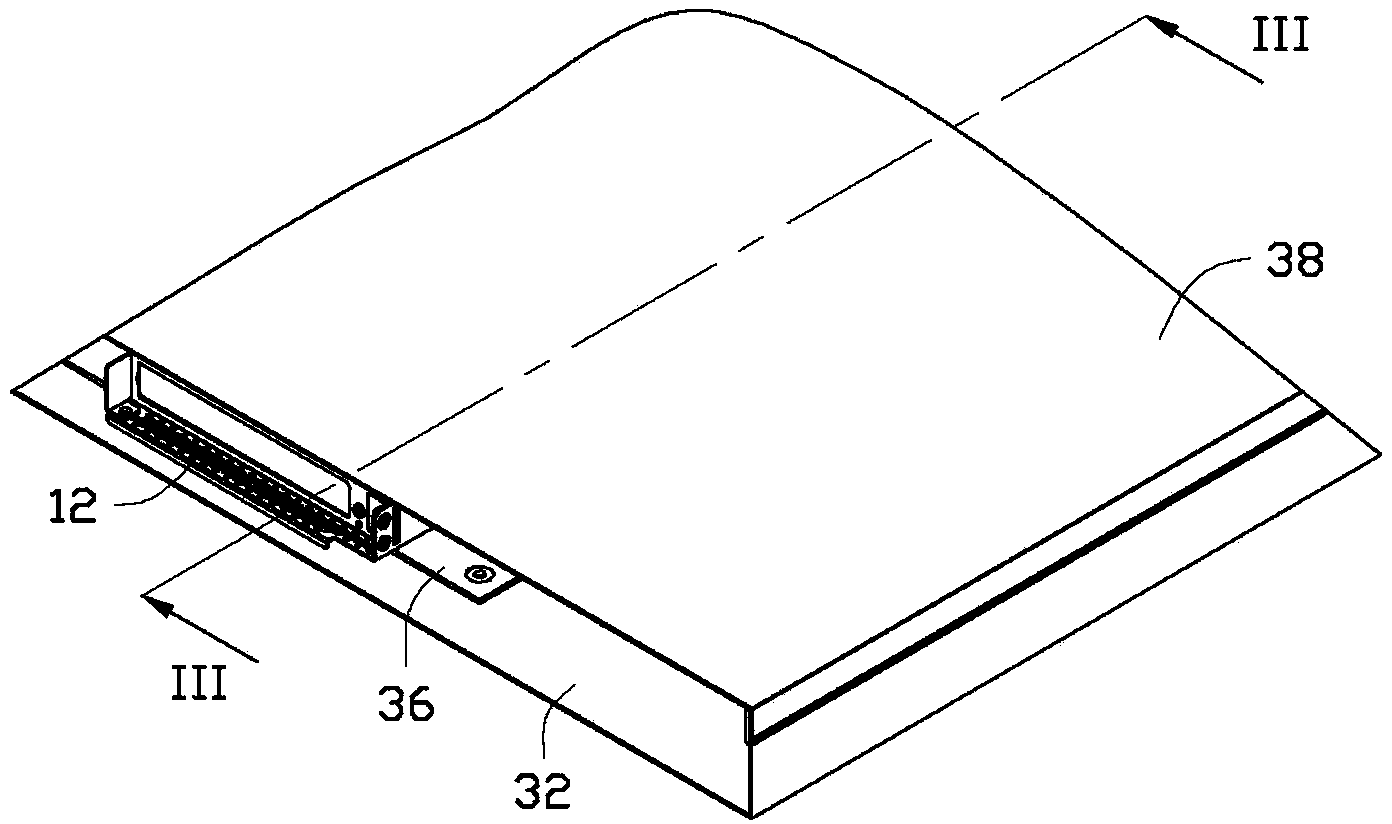

[0013] Please refer to figure 1 with image 3 The preferred embodiment of the riser card assembly module 10 of the present invention is to install a riser card 20 in a housing 30.

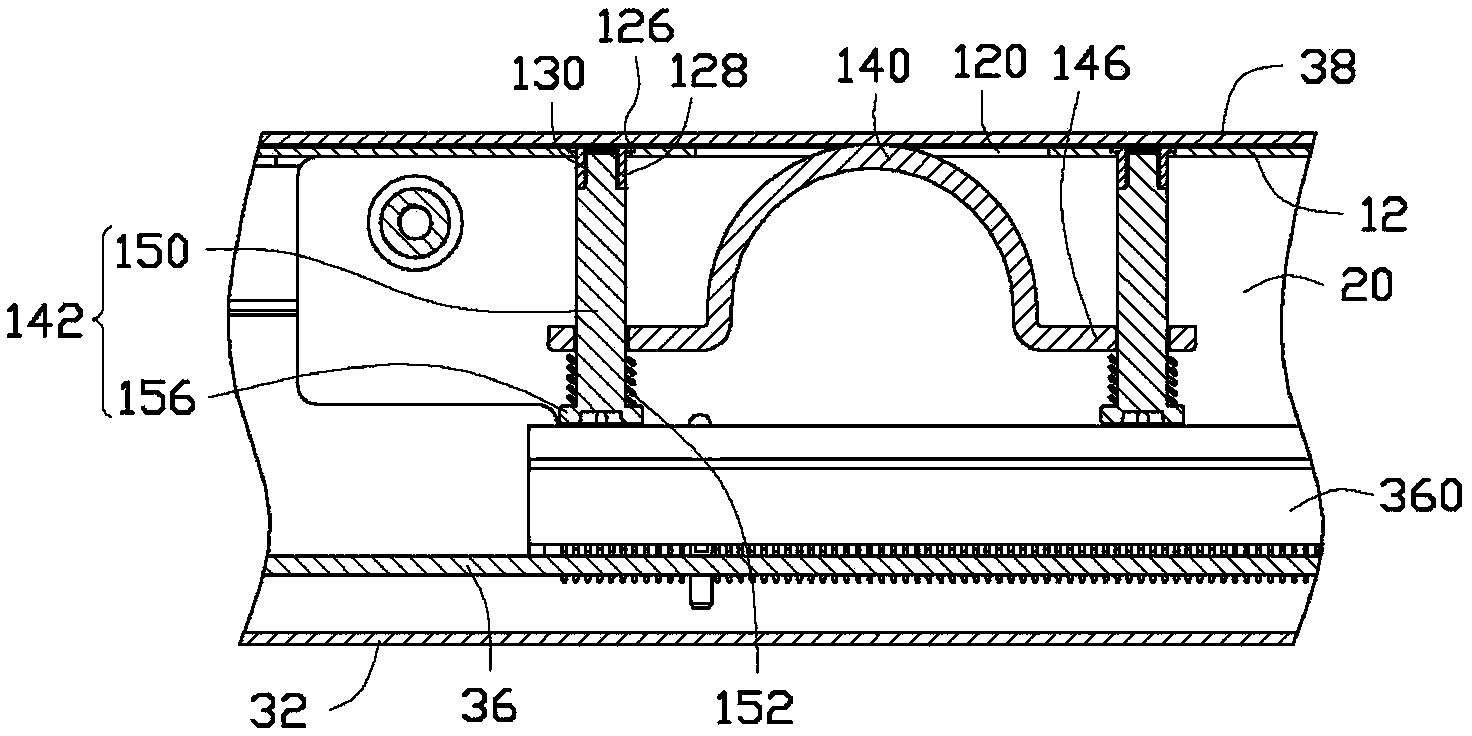

[0014] The casing 30 includes a base and an upper cover 38 assembled on the base. The base includes a bottom plate 32. A motherboard 36 is fixed on the bottom plate 32. A connector slot 360 protrudes from the motherboard 36.

[0015] The riser card assembly module 10 includes a body 12 and a pullout member 14.

[0016] The body 12 includes a top wall 13 and a side wall 15. The top wall 13 defines an opening 120 extending to the side wall 15 and two through holes 122 respectively located on two sides of the opening 120. A nut 124 is assembled in each through hole 122. The nut 124 includes a cylinder 128 penetrating through the through hole 122 and a blocking portion 126 disposed at one end of the cylinder 128 and capable of blocking the top surface of the top wall 13. The cylinder 128 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com