Winding inter-plate electrical connection structure

An electrical connection structure and wire-wound technology, applied in the field of wire-wound board-to-board electrical connection structures, can solve the difficulty in meeting the requirements of reliability and long life of electrical connection structure contacts, increased occlusal force/insertion force, Reliability reduction and other problems, to achieve the effect of improving electrical contact reliability, reducing performance degradation, and improving connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

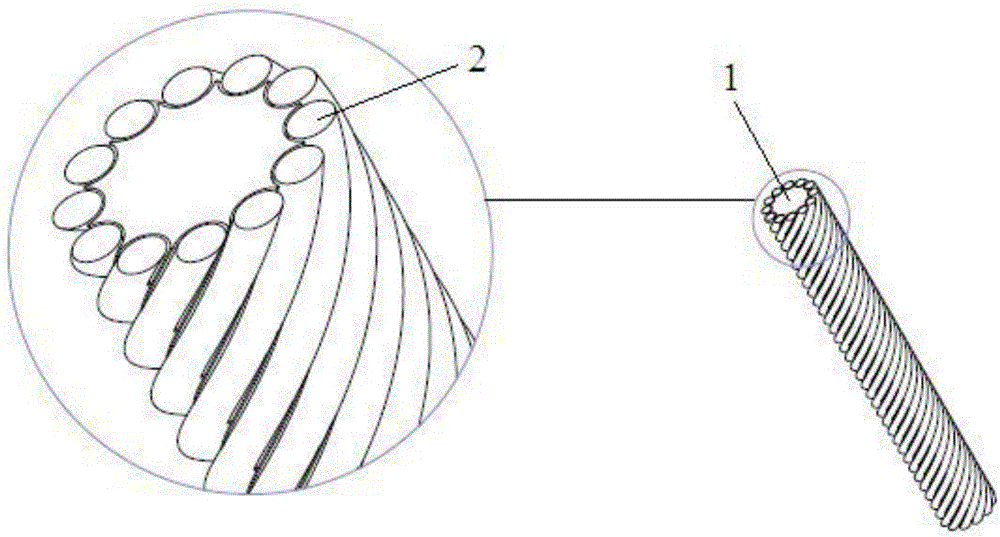

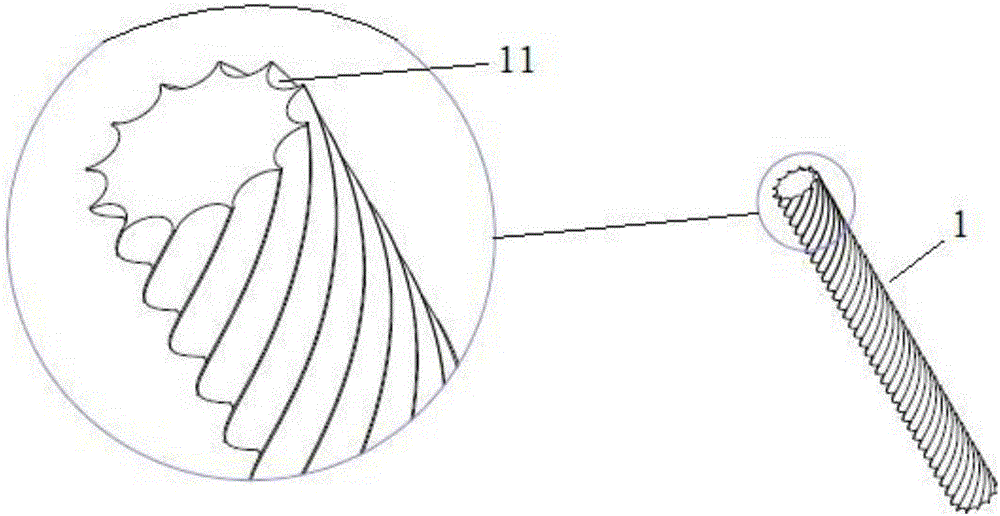

[0038] reference figure 1 with figure 2 As shown, the outer circumference of the support 1 is provided with a plurality of winding grooves 11, and the two ends of each winding groove 11 respectively extend to the two ends of the support 1; each conductive member 2 is respectively wound around the outer circumference of the support 1 along a single winding groove 11 , And a plurality of conductive elements 2 can be connected to each other.

[0039] The support can be a wire with a circular, elliptical, square, polygonal or other shape in cross section. After the winding groove is provided, the outer periphery of the cross section of the support is zigzag. The winding groove provided on the outer periphery of the support member can guide and support the conductive member. The supporting member can be a conductor or an insulator. Since the supporting member mainly functions to support the external conductive member, its conductivity can be selected as required.

Embodiment 2

[0041] In this embodiment, the support 1 is not provided with a winding groove, but the outer surface is smooth, and the conductive member 2 is directly wound around the smooth outer periphery of the support to form an elastic winding contact element. When the elastic wire-wound contact element is bent as a whole, the supporting member 1 can also support the conductive member 2 wound on the outside thereof, thereby improving structural stability and prolonging the service life. This embodiment is not the focus of protection of the present invention, and will not be repeated.

Embodiment 3

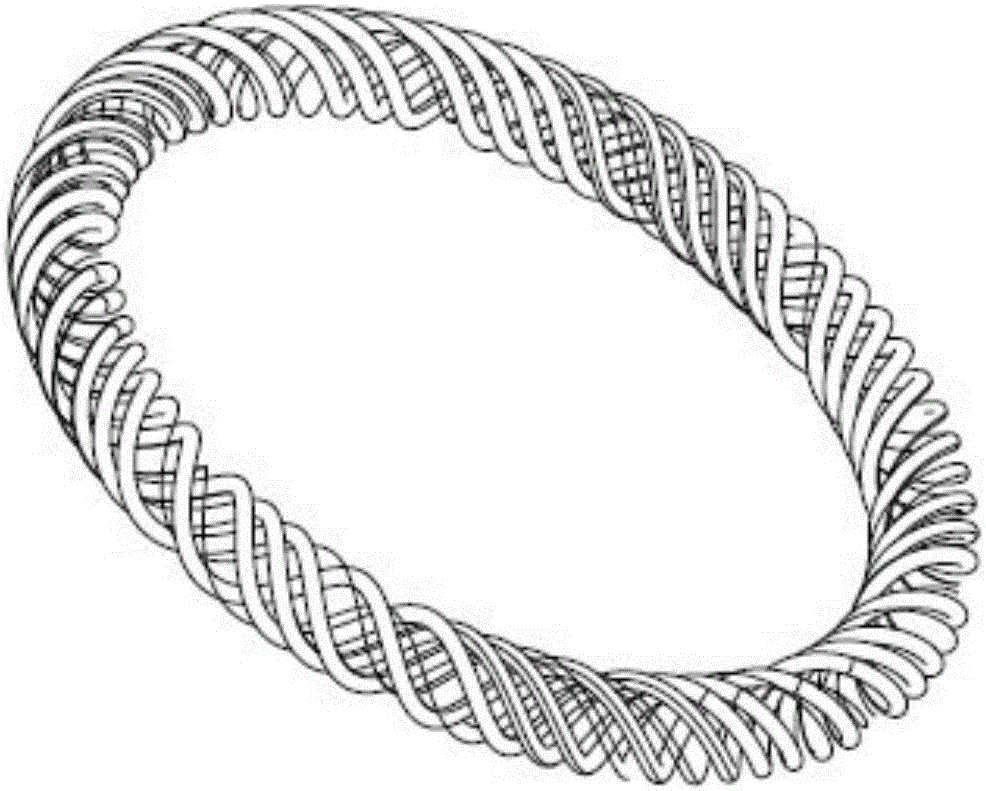

[0043] On the basis of embodiment 1 or embodiment 2, in this embodiment, the elastic wire-wound contact element formed by winding the conductive member 2 on the support 1 is integrally bent, that is, the support member is bent into a ring shape. The contact element can be applied to the pin or socket, and the electrical connection performance is reliable. In this case, in order to finally form a multi-contact conductive whole between the plurality of conductive members 2, that is, the plurality of conductive members can be electrically connected to each other, the winding method of the plurality of conductive members on the support member There are also many kinds, the following preferably, each winding groove is arranged in a spiral manner on the outer periphery of the support member to expand the embodiment:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com