A high-strength connector termination structure

A connector, high-strength technology, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems of increasing the procurement cost of crimping tools, being unsuitable for high-current connectors, reducing the elastic force of shrapnel, and achieving structural Simple, low cost, and the effect of ensuring connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

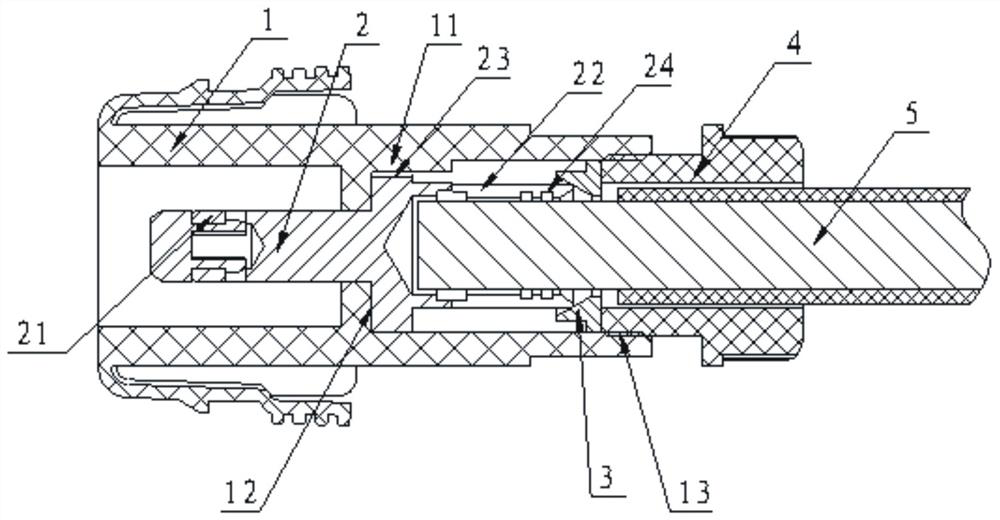

[0021] refer to figure 1 , The present invention includes a housing 1, a contact piece 2, a compression ring 3 and a pressure cap 4 at the end.

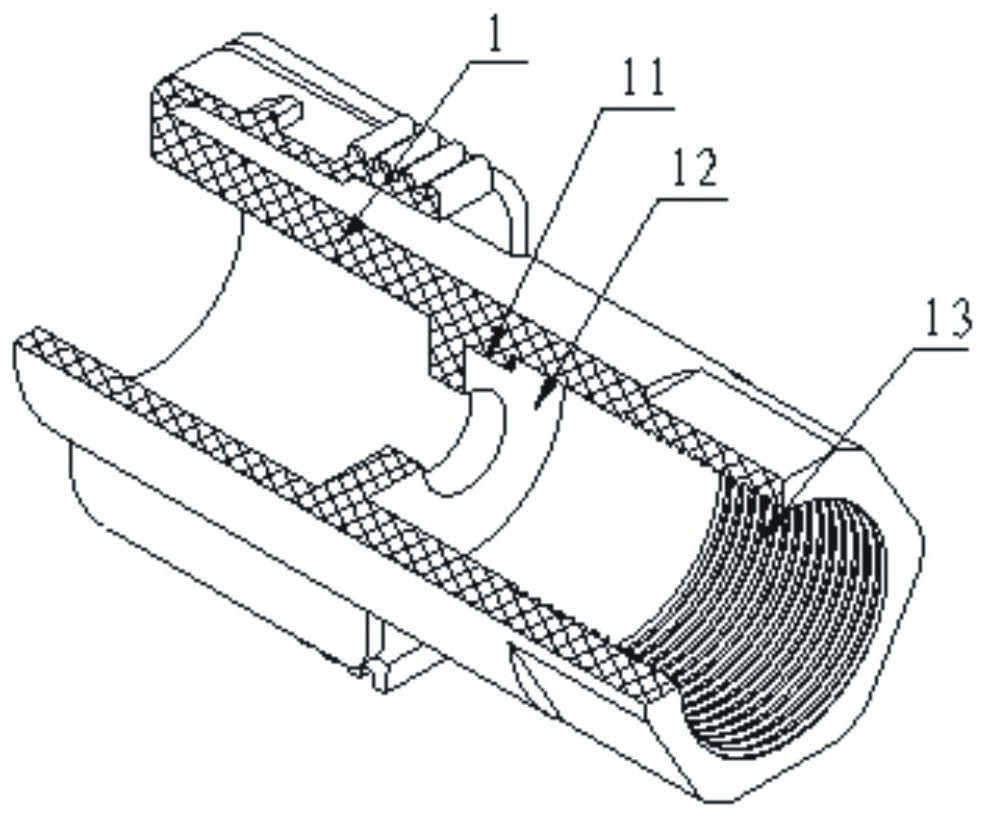

[0022] refer to figure 1 , figure 2 , the shell 1 is a cylindrical member, a stepped hole 12 and an internal thread 13 are provided in the cylinder, and a positioning convex key 11 is provided on the inner wall of the cylinder.

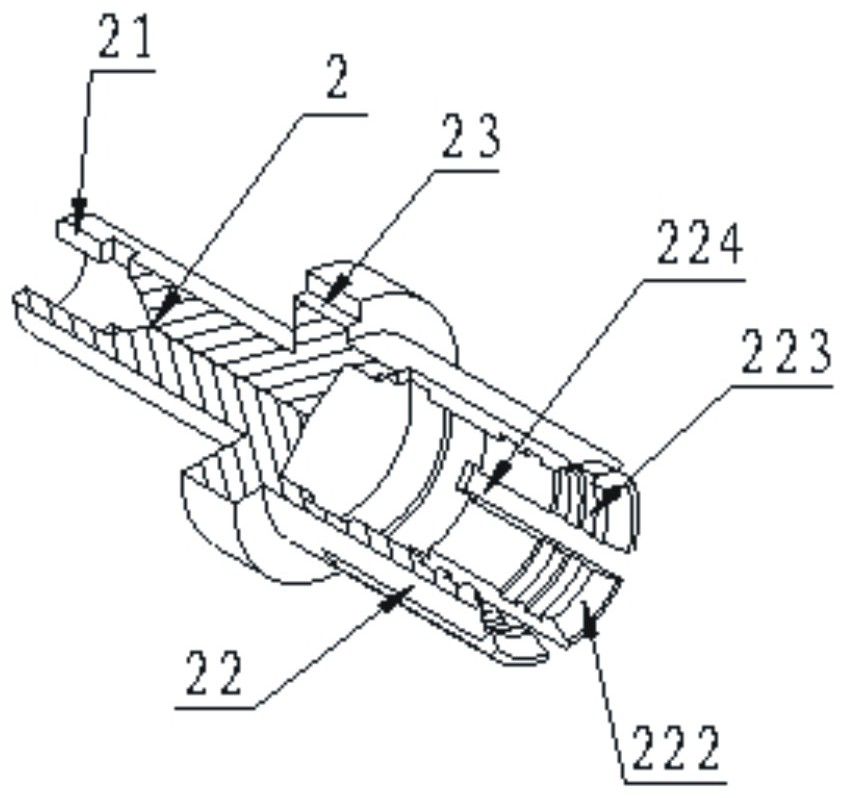

[0023] refer to figure 1 , image 3 , the contact piece 2 is a shaft-shaped member with a contact 21 at one end, an elastic cylinder wall 22 at the other end, and a limit boss in the middle. A keyway 23 is provided on the limit boss, and the circumference of the elastic cylinder wall 22 A plurality of elastic arms 222 are provided, and engaging teeth 223 are provided inside the elastic arms 222 .

[0024] refer to figure 1 , Figure 4 , the pressing ring 3 is a ring member, and the inner hole of the ring member is provided with a bell mouth 31 .

[0025] refer to figure 1 , Figure 5 , the tail-en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com