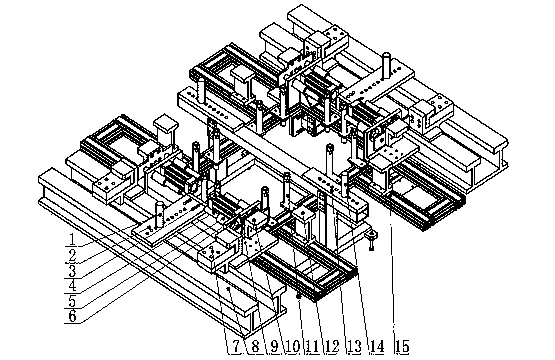

Frame disassembling mechanism

A short-side and long-side technology, applied in the field of solar energy production line equipment, can solve the problem of only being dismantled, and cannot automatically dismantle the four sides at the same time, so as to avoid the effect of manual dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and examples.

[0018] The invention proposes a frame removal mechanism. refer to figure 1 As shown, a frame removal mechanism, the short-side retaining post 1 is fixed on the short-side retaining post seat plate 2, and a cylinder 3 is installed next to the short-side retaining post seat plate 2, and the cylinder 3 is installed on the cylinder seat 6, The cylinder block 6 is fixed with a guide rod 4 and a linear bearing 5, and the rod member of the cylinder 3 and the guide rod 4 are respectively connected with the cylinder top plate 9, and the cylinder top plate 9 is connected with the long side clamp 10, and the Next to cylinder top plate 9, short side clamp 7 is installed, short side clamp support 8 is installed below described short side clamp 7, universal ball support 11 is arranged beside described long side clamp 10, described universal ball support 11 and worker sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com