Delivery device of capsule detector

A technology of capsule detection machine and conveying device, which is applied in the direction of sorting, etc., which can solve the problem that the end of the capsule cannot be photographed facing inward, and achieve the effect of expanding the detection range and improving the rejection rate of waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

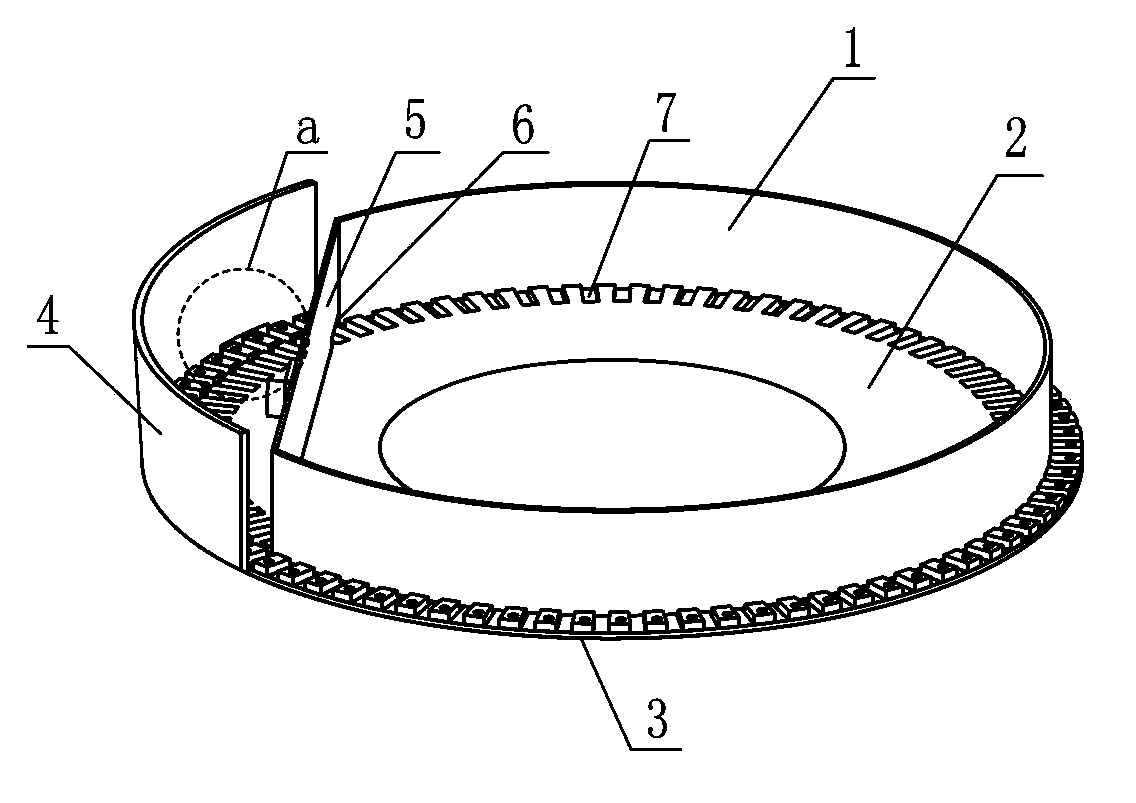

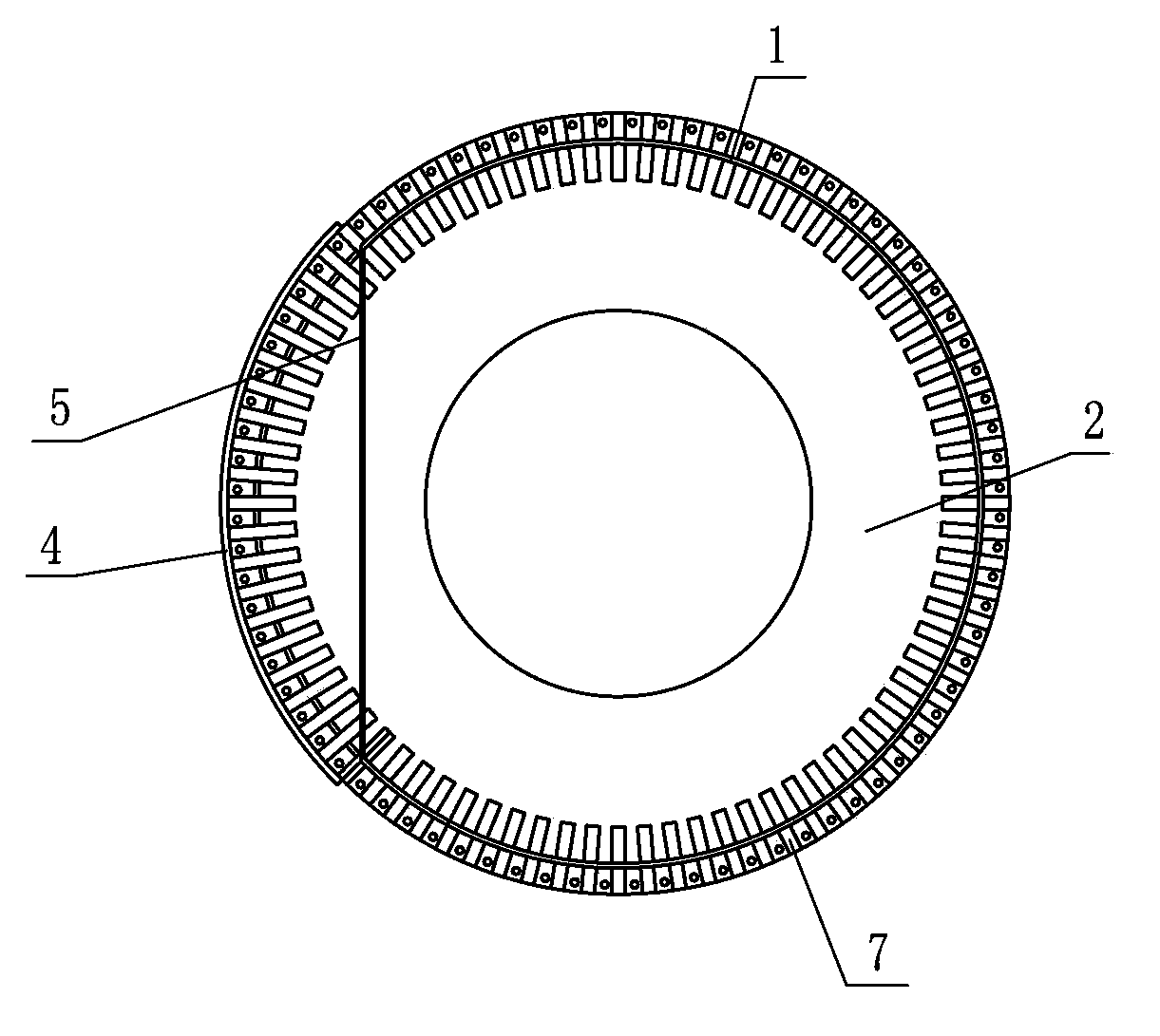

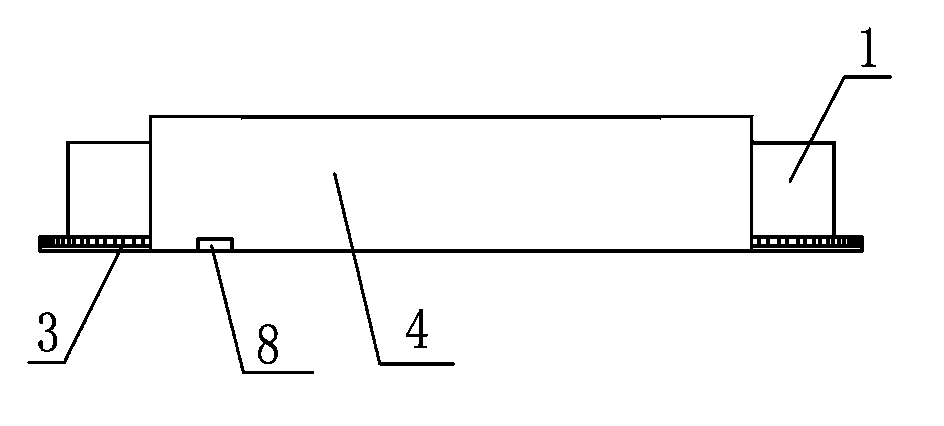

[0018] Such as Figure 1 to Figure 5 As shown, the present invention includes a turntable 2, a chassis 3, an inner baffle, an outer baffle 4, and a rejecting mechanism. The drive mechanism is connected to the turntable 2 through a transmission mechanism. The edge of the turntable is provided with 80 through the top surface of the turntable and The opening groove 7 on the bottom surface, the opening groove 7 is arranged along the circle centered on the turntable, the side of the turntable is connected with the opening groove 7, and the length of the opening groove 7 is greater than the length of the capsule. The inner ends are separated by a certain distance, and the top surface of the turntable is provided with an annular groove 11, which is concentric with the turntable 2 and spans the open slot 7; the chassis 3 and the turntable 2 are stacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com