Easy-to-operate 10-fold profile leveling tool

A nine-fold profile and easy-to-operate technology, applied in the field of nine-fold profile leveling tooling, can solve the problems of inconvenient operation and large structure, and achieve the effect of easy operation, simple structure and simple structure for angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

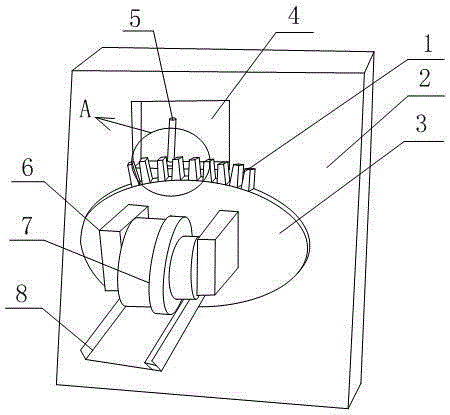

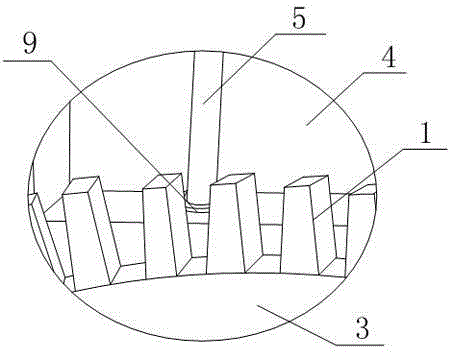

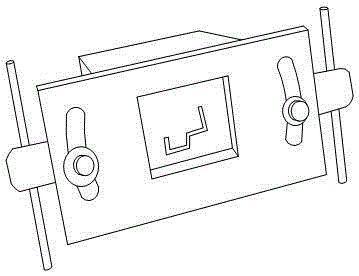

[0018] like figure 1 and figure 2 The shown is an easy-to-operate nine-fold profile leveling tool, including a fixed plate 2 and a circular turntable 3 movably arranged on the fixed plate 2, and a plurality of protrusions 1 are arranged on the edge of the circular turntable 3 , the circular turntable 3 is provided with two fixed blocks 6, and a leveling roller 7 is movable between the two fixed blocks 6, and the circular turntable 3 is provided with a conveying trough 8, the described The gap between the conveying trough 8 and the leveling roller 7 matches the cross-section of the nine-fold profile, the circular turntable 3 is provided with a conveying hole, and the conveying hole is located above the conveying trough 8, and the described The fixing plate 2 is also provided with a locking device that cooperates with the protrusion 1 to fix the circular turntable 3 .

[0019] In this embodiment, the circular turntable 3 is used to adjust the angle of nine-fold profile proce...

Embodiment 2

[0023] like figure 1 and figure 2 Shown is an easy-to-operate nine-fold profile leveling tool. This embodiment makes the following refinements on the basis of Embodiment 1: that is, the locking device includes a locking lever 5 and can make the locking lever 5 A base 9 that rotates on a plane and the plane is perpendicular to the circular turntable 3 . The circular turntable 3 is fixed by the cooperation of the locking rod and the protrusion, and the structure is simple and easy to operate.

[0024] In order to prevent the locking lever 5 from affecting the operation of the circular turntable 3 when the circular turntable 3 is rotated, the fixed plate 2 is provided with a groove 4, and the base 9 is located in the groove 4 Inside.

[0025] In order to facilitate the locking rod to fix the protrusion, the distance between two adjacent protrusions 1 is greater than the diameter of the locking rod 5 .

[0026] The operation process of this embodiment is as follows:

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com