Tool for rapidly penetrating screw gaskets in sleeved mode

A screw threading technology, which is applied in the field of fast threading screw gasket tools, can solve the problems of low threading efficiency, affecting the operator's enthusiasm for work, and easy fatigue, so as to enhance work enthusiasm, improve efficiency, and reduce fatigue Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

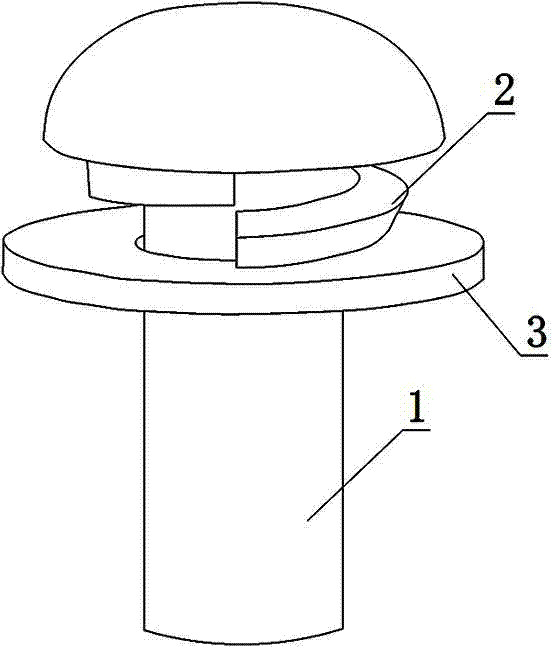

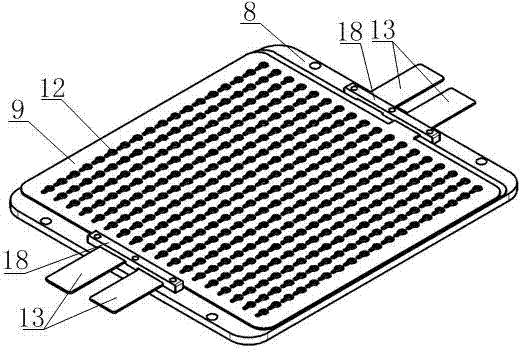

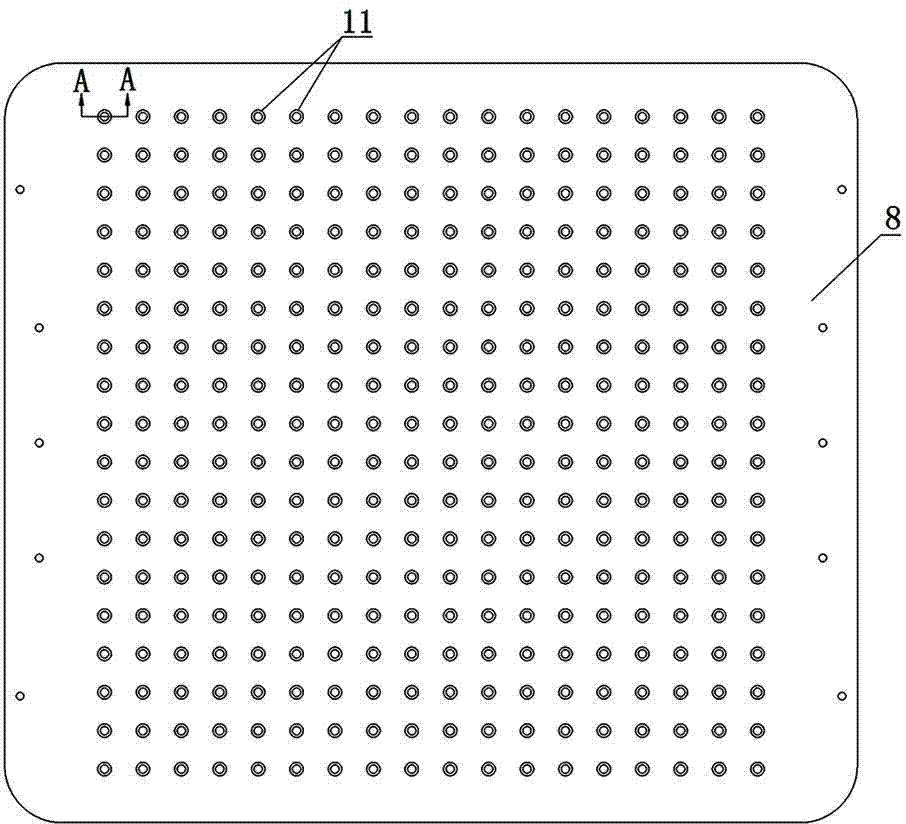

[0031] A quick threading screw washer tool, which includes an assembly part 4, a screw carrier plate 5, a flat washer carrier plate 7 and a spring washer carrier plate 6; as figure 2 As shown, the assembly part 4 includes an assembly motherboard 8, an upper splint 9 and a lower splint 10, as image 3 , Figure 4 As shown, the assembly motherboard 8 is provided with accommodating holes 11 distributed in an array for accommodating screw heads. The diameter of the accommodating holes 11 is greater than the outer diameter of the screw heads, and the depth of the accommodating holes 11 is greater than that of the screw heads. The sum of the thickness of the head, the thickness of the spring washer, and the thickness of the flat washer, the bottom of the preferred accommodating hole 11 is also provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com