Cutting element having modified surface

A technology of cutting elements and cutting surfaces, applied in the field of manufacturing cutting elements using cutting elements, drill bits and tools equipped with such cutting tools, to achieve the effect of long wear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

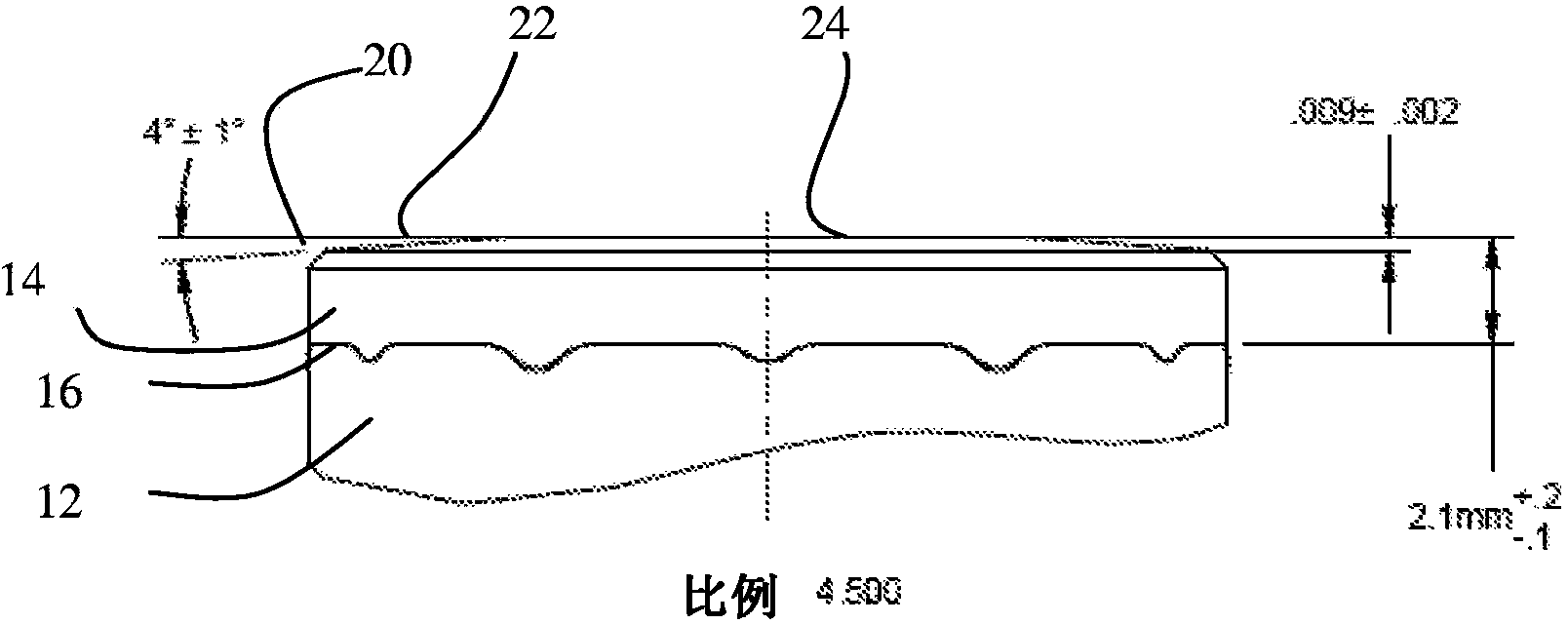

[0054] An improved cutting element is disclosed. The cutting element may be used, but is not limited to, superabrasive tools such as those used in drag bits. Improved cutting elements include reduced chipping, improved wear resistance, and longer tool life, among other improvements. The improvement is at least partially attributable to the addition of a first portion of the cutting face of the cutting element having an angle of about 81° to about 89° relative to the longitudinal axis of the cutting element.

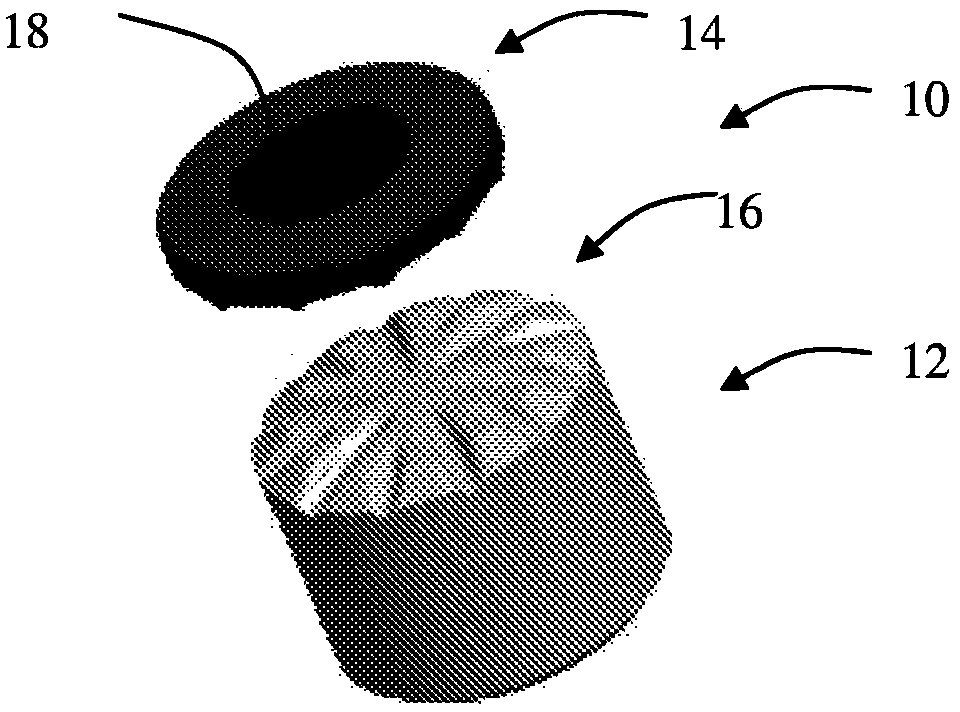

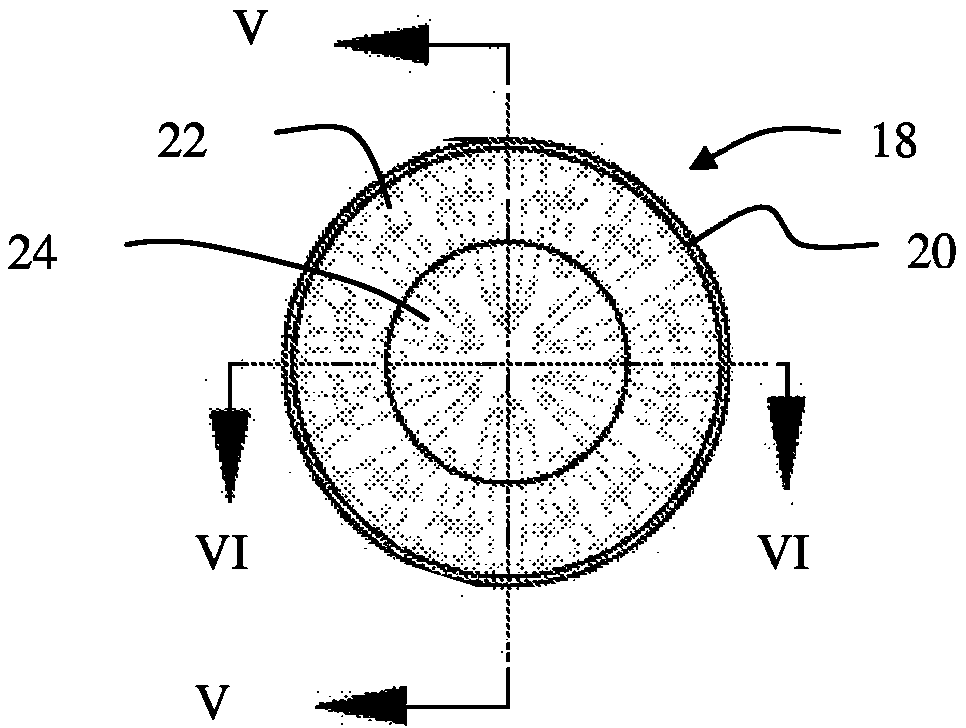

[0055] exist Figure 1 to Figure 6 A first embodiment of a tool comprising an improved cutting face is shown in . Cutting element 10 includes a substrate 12 , a superabrasive layer 14 , and an interface 16 between substrate 12 and superabrasive layer 14 . The superabrasive layer 14 includes a cutting face 18 that forms the top surface of the cutting element 10 . In an embodiment, the cutting face may include a chamfer 20 , a first portion 22 and a second portion 24 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com