Concrete conveying cylinder and manufacturing process thereof

A manufacturing process and delivery cylinder technology, which is applied to components of pumping devices for elastic fluids, variable displacement pump components, machines/engines, etc., can solve the problem of large wear of chrome plating layer, low hardness, and consumption rate of concrete delivery cylinders Advanced problems, to achieve the effect of low cost and improved wear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

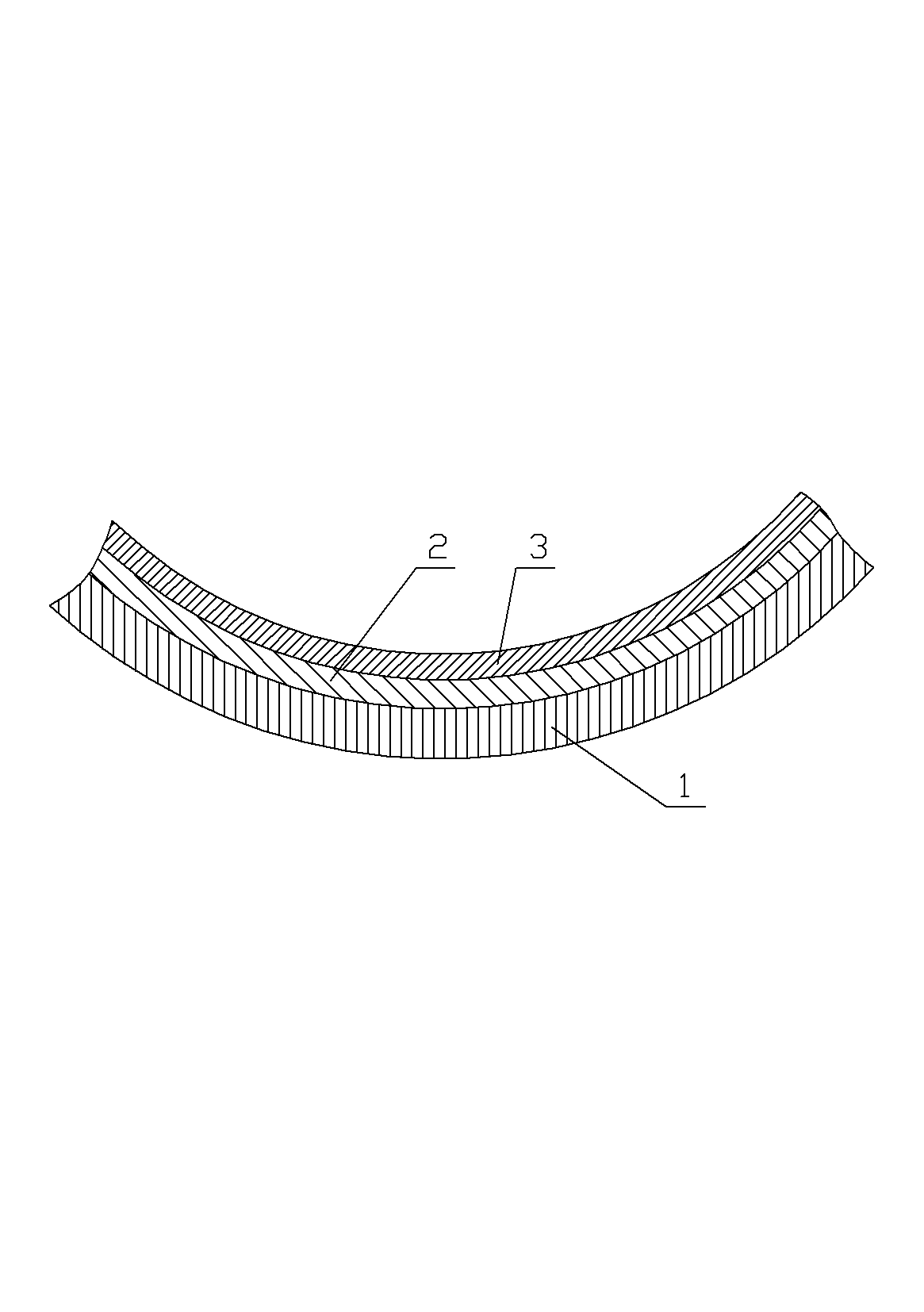

Image

Examples

specific Embodiment 1

[0033] a. Quenching and tempering the hot-rolled steel pipe of 45# steel, so that the hardness range is 200HB;

[0034] b. Boring the quenched and tempered 45# hot-rolled steel pipe to form inner holes;

[0035] c. Honing the surface of the inner hole so that the surface roughness is 0.2 μm;

[0036] d. The surface of the inner hole after honing is processed by a plasma arc surface quenching process to form a quenched layer. The thickness of the quenched layer is 0.1mm, and the surface hardness of the quenched layer is 530HV;

[0037] e. Honing the surface of the quenched layer to make the surface roughness 0.2 μm;

[0038] f. Carry out electroplating on the surface of the quenched layer after honing to produce an electroplating layer. The electroplating layer is specifically a chrome-plated layer, and the thickness of the chrome-plated layer is 0.3mm.

specific Embodiment 2

[0039] a. Quenching and tempering the hot-rolled steel pipe of 45# steel, so that the hardness range is 270HB;

[0040] b. Boring the quenched and tempered 45# hot-rolled steel pipe to form inner holes;

[0041] c. Honing the surface of the inner hole so that the surface roughness is 0.1 μm;

[0042] d. The surface of the inner hole after honing is processed by a plasma arc surface quenching process to form a quenched layer. The thickness of the quenched layer is 0.3mm, and the surface hardness of the quenched layer is 667.5HV;

[0043] e. Honing the surface of the quenched layer to make the surface roughness 0.1 μm;

[0044] f. Carry out electroplating on the surface of the quenched layer after honing to produce an electroplating layer. The electroplating layer is specifically a chrome-plated layer, and the thickness of the chrome-plated layer is 0.2 mm.

specific Embodiment 3

[0045] a. The hot-rolled steel pipe of 45# steel is subjected to quenching and tempering treatment, so that the hardness range is 235HB;

[0046] b. Boring the quenched and tempered 45# hot-rolled steel pipe to form inner holes;

[0047] c. Honing the surface of the inner hole so that the surface roughness is 0.15 μm;

[0048] d. The surface of the inner hole after honing is processed by a plasma arc surface quenching process to form a quenched layer. The thickness of the quenched layer is 0.8mm, and the surface hardness of the quenched layer is 700HV;

[0049] e. Honing the surface of the quenched layer so that the surface roughness is 0.15 μm;

[0050] f. Carry out electroplating on the surface of the quenched layer after honing to produce an electroplating layer. The electroplating layer is specifically a chrome-plated layer, and the thickness of the chrome-plated layer is 0.25 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com