A single flat disc permanent magnet eddy current coupling with fixed end face

A permanent magnet eddy current, flat disk technology, applied in the direction of permanent magnet clutch/brake, asynchronous induction clutch/brake, etc., can solve the problem of reduced effective working life, inconvenient installation work, increased prime mover or load drive shaft support bearing Force and other problems, to achieve the effect of preventing long-term overload, preventing rapid heating, and simplifying the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

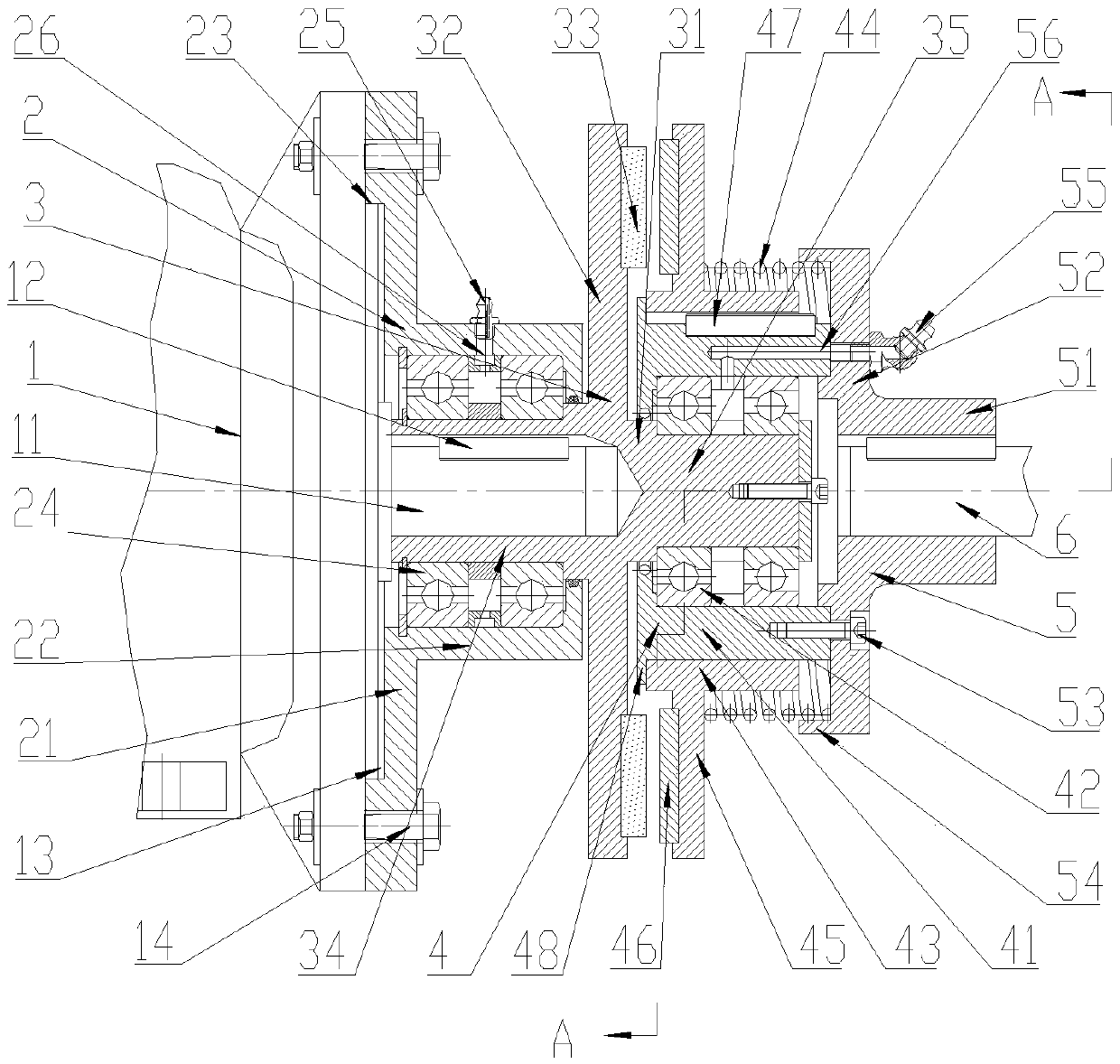

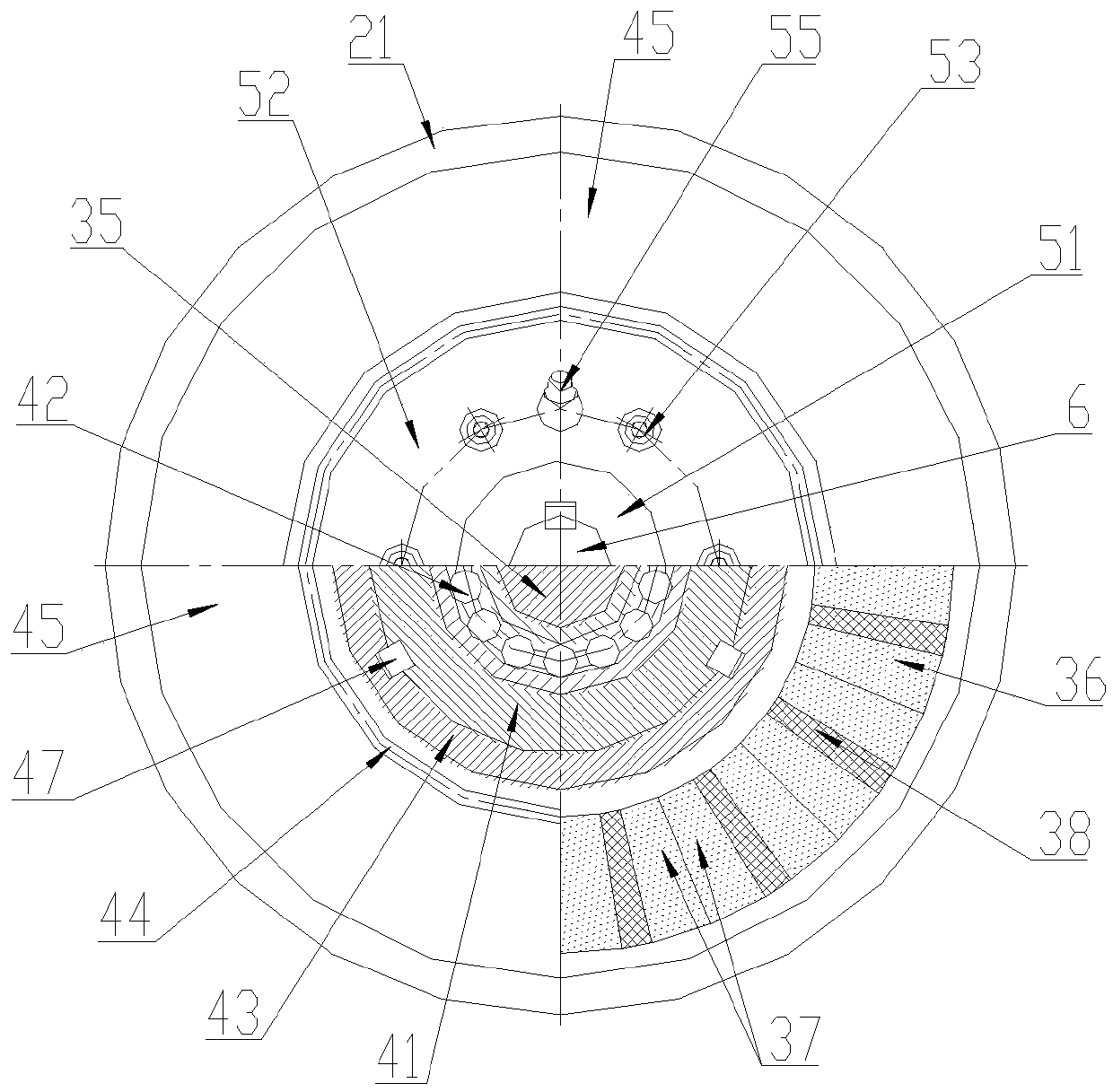

[0017] Such as figure 1 , figure 2 As shown, a single flat disc permanent magnet eddy current coupling with a fixed end face includes a coaxially arranged driving rotor 3, a driven rotor 4, an end face positioning seat 2 and an end cover shaft 5; the driving rotor 3 is composed of a driving Rotor shaft 31, disk-shaped magnetic rotor disc 32 and permanent magnet layer 33; the section of active rotor shaft 31 close to motor 1 is hollow shaft section 34, and hollow shaft section 34 is a cylindrical structure. The inner wall is provided with a first keyway, which is used to cooperate with the motor shaft key 12 arranged on the motor shaft 11 of the B35 model motor 1. There is no movement between the hollow shaft section 34 of the active rotor shaft 31 and the motor shaft 11. The dynamic fit of the gap; the section of the active rotor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com