A coaxial sleeve type permanent magnet eddy current governor with fixed end face

A permanent magnet eddy current and speed governor technology, applied in electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of increasing the force of the prime mover or the load-driven shaft support bearing, reducing the effective working life, and difficulty in concentric positioning. , to achieve the effect of reducing workload and reducing installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

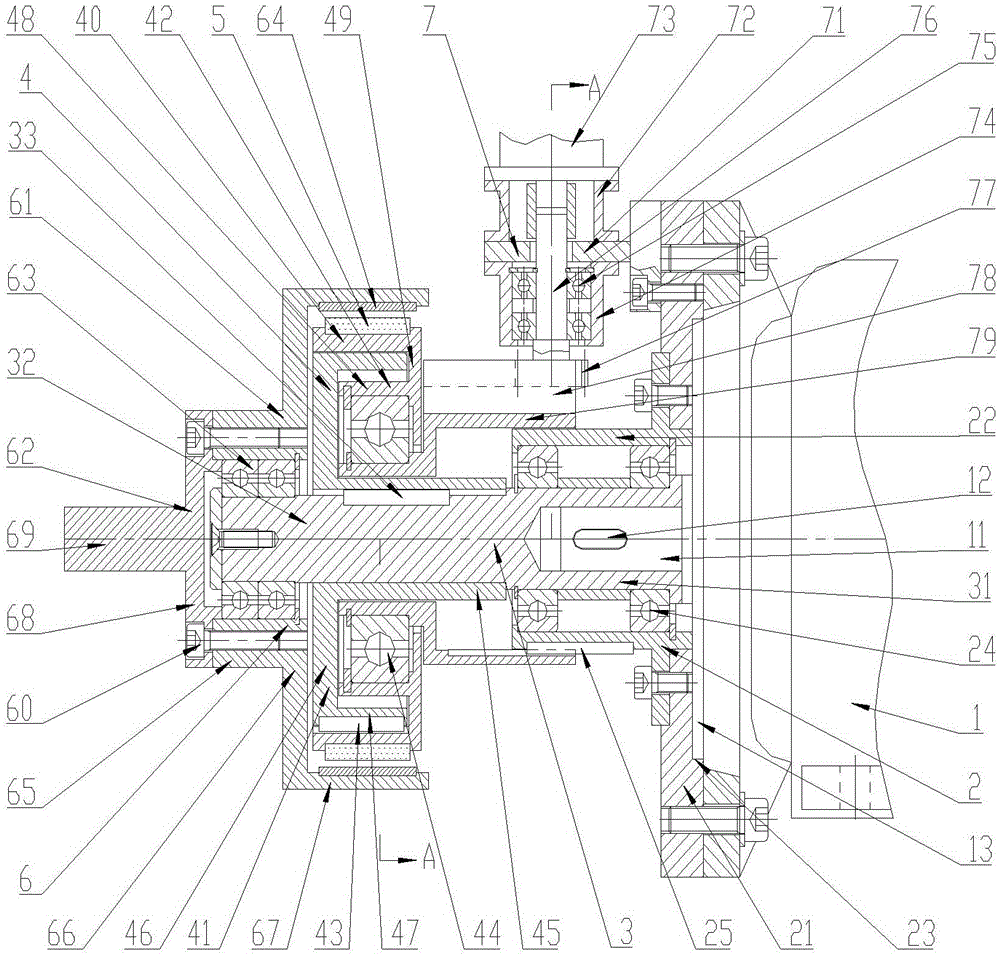

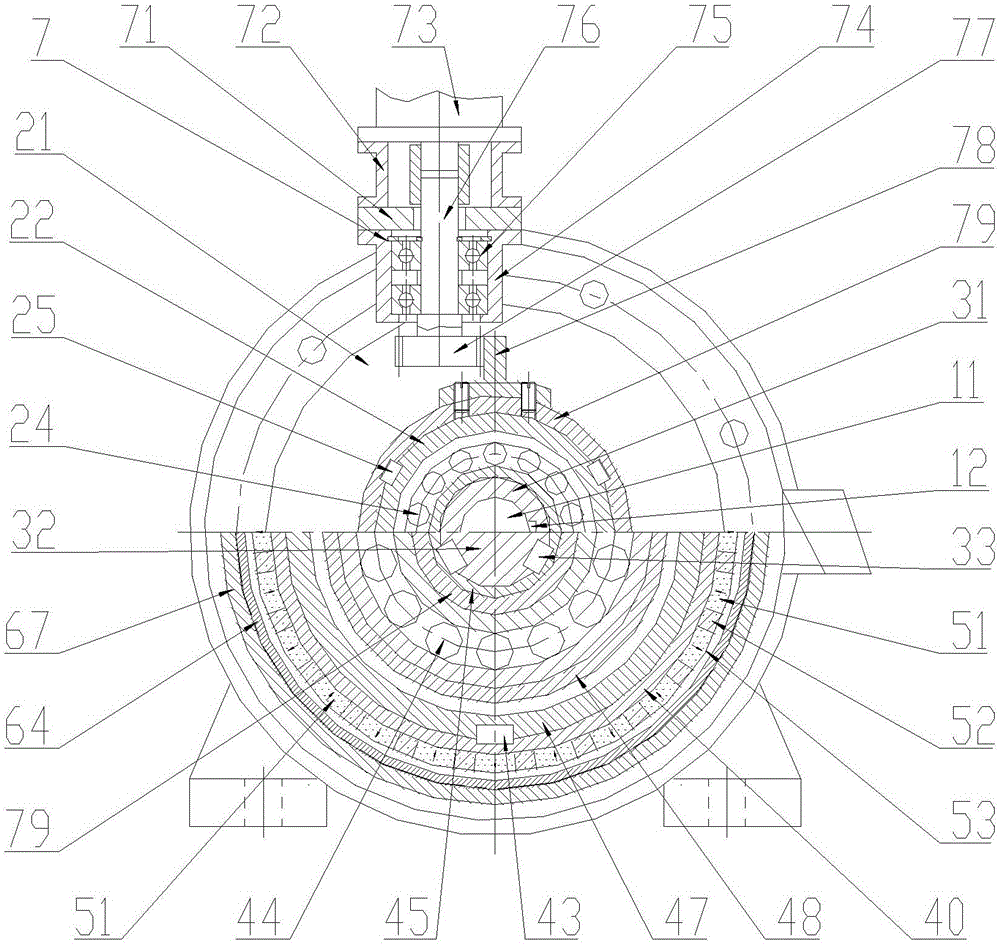

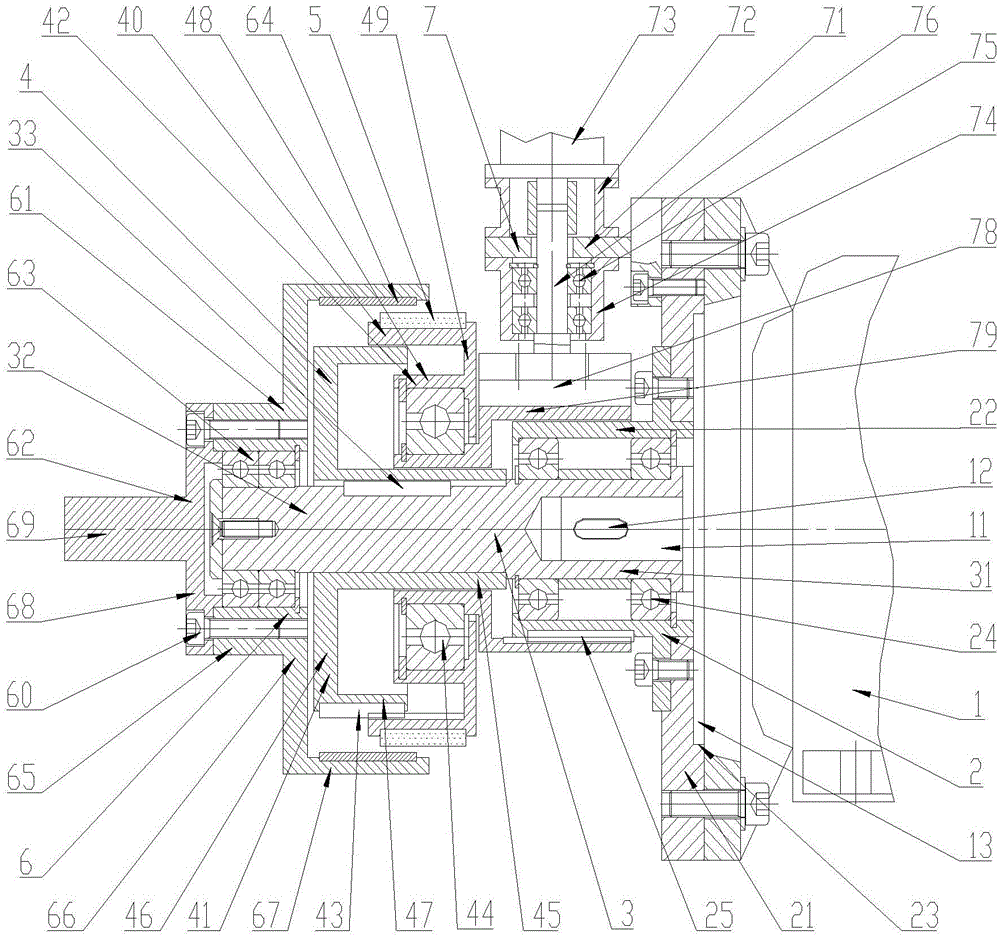

[0017] Such as figure 1 , figure 2 , image 3 As shown, a coaxial sleeve type permanent magnet eddy current speed governor with fixed end face includes a driving rotor 4, an end face positioning seat 2, a transition shaft 3, a driven rotor 6 and a speed regulating mechanism 7, and the driving rotor 4 is composed of The coaxially arranged fixed rotor body 41, the sliding rotor body 42 and the permanent magnet layer 5 are composed of the coaxially arranged fixed inner cylinder 45, the middle support plate 46 and the fixed outer cylinder 47. The fixed inner circle The cylinder 45 and the fixed outer cylinder 47 are both cylindrical structures, and are fixed on the inner side wall of the disc-shaped middle support plate 46 facing the motor 1, and the fixed inner cylinder 45 is arranged inside the fixed outer cylinder 47; The sliding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com