A coaxial sleeve type permanent magnet eddy current coupling with fixed end faces

A permanent magnet eddy current, sleeve-type technology, applied in the direction of controlling mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of increasing the force of the prime mover or load shaft supporting bearings, reducing the effective working life, and poor working conditions, etc., to achieve The effect of reducing the workload and simplifying the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

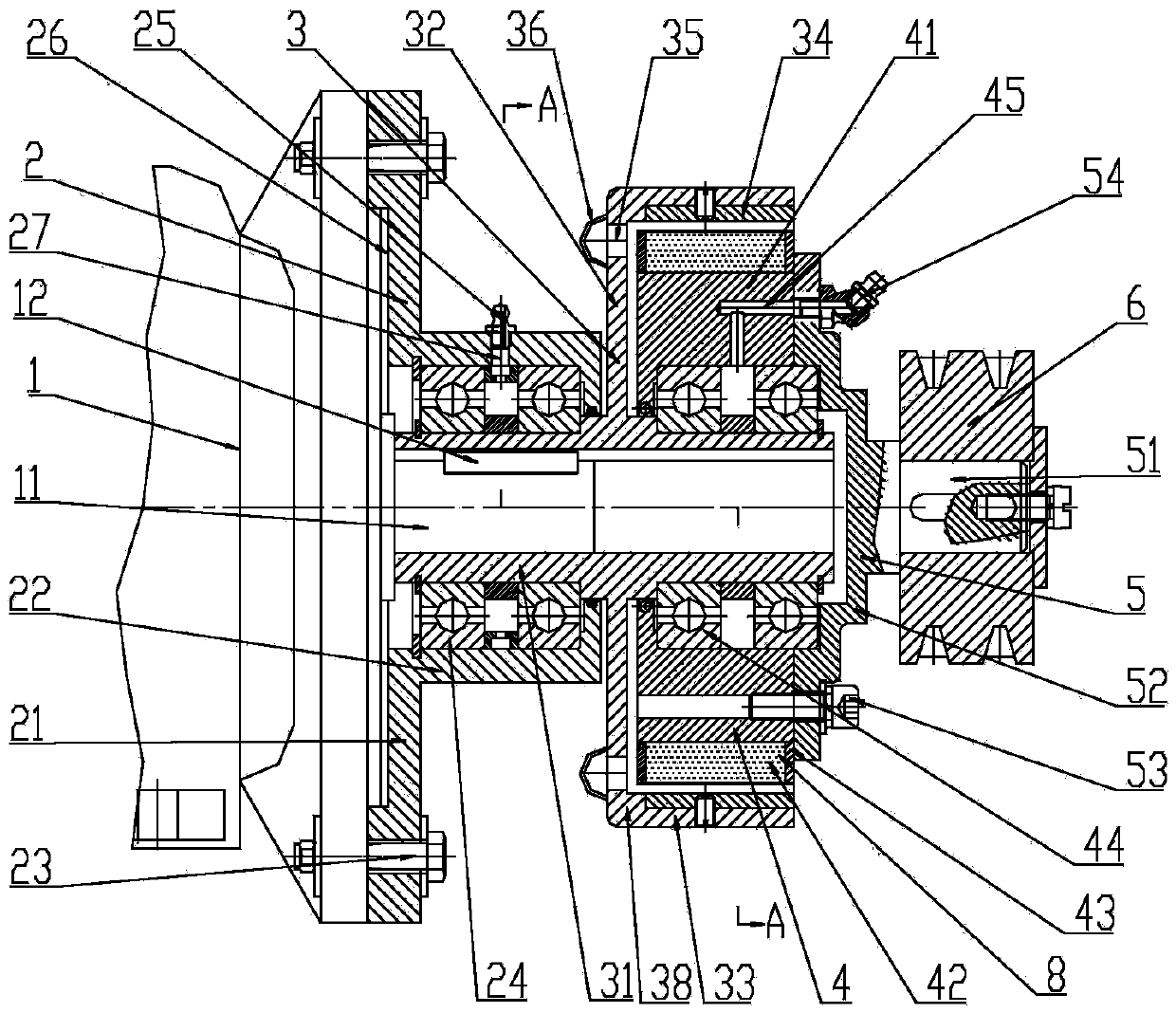

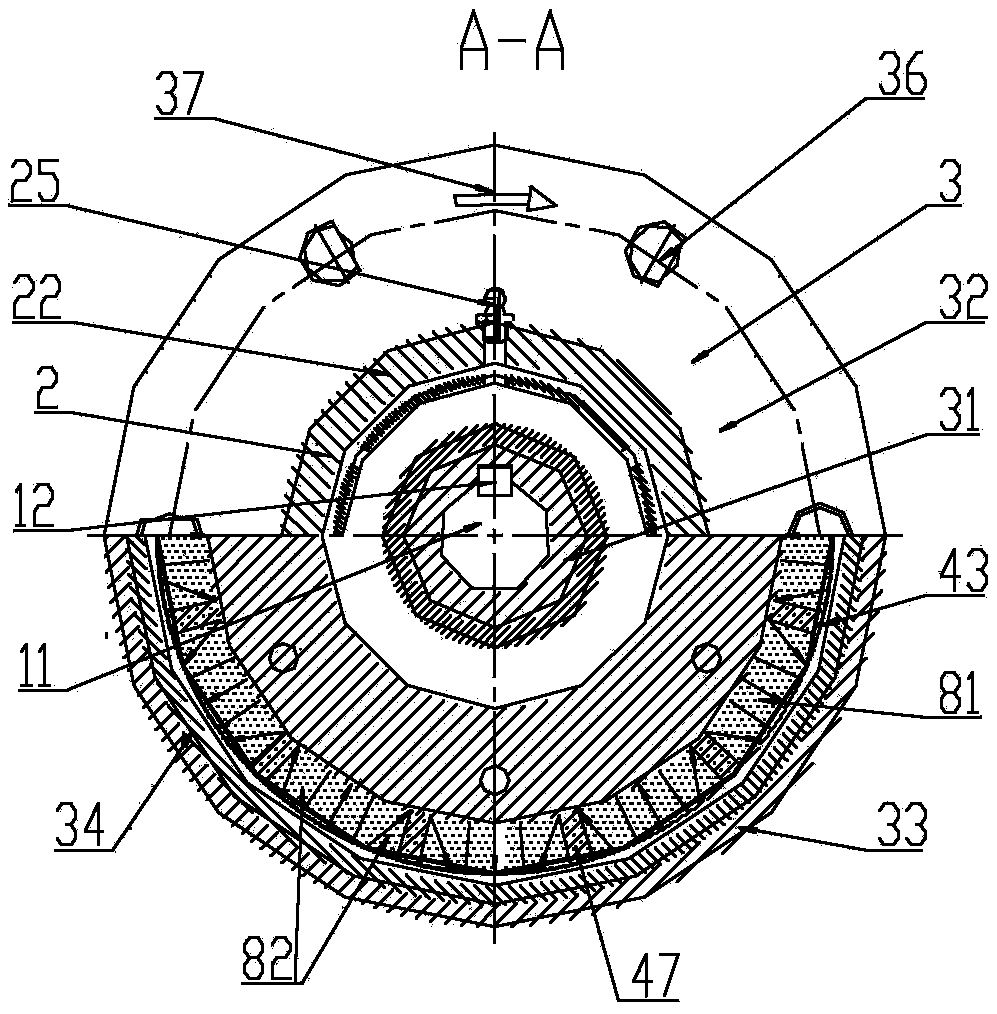

[0023] Such as figure 1 , figure 2As shown in the figure, a coaxial sleeve type permanent magnet eddy current coupling with fixed end face includes a coaxial end face positioning seat 2, a driving rotor 3 and a driven rotor 4; the driving rotor 3 is used as the outer rotor, and the driving rotor body 38 and the eddy current ring 34 fixed on the active rotor body 38; the active rotor body 38 is composed of a hollow shaft 31, an outer liner 33 and a middle support plate 32, and the hollow shaft 31 is a cylindrical structure, which is arranged on the active rotor At the center of the body 38, the middle support plate 32 is a disc-shaped structure, which is coaxially fixed in the middle of the outer wall of the hollow shaft 31; the outer liner 33 is a thin-walled cylindrical structure, made of magnetically conductive material, and fixed on the middle support plate 32 side, the outer liner 33 is coaxially arranged with the hollow shaft 31; the inner side wall of the hollow shaft ...

Embodiment 2

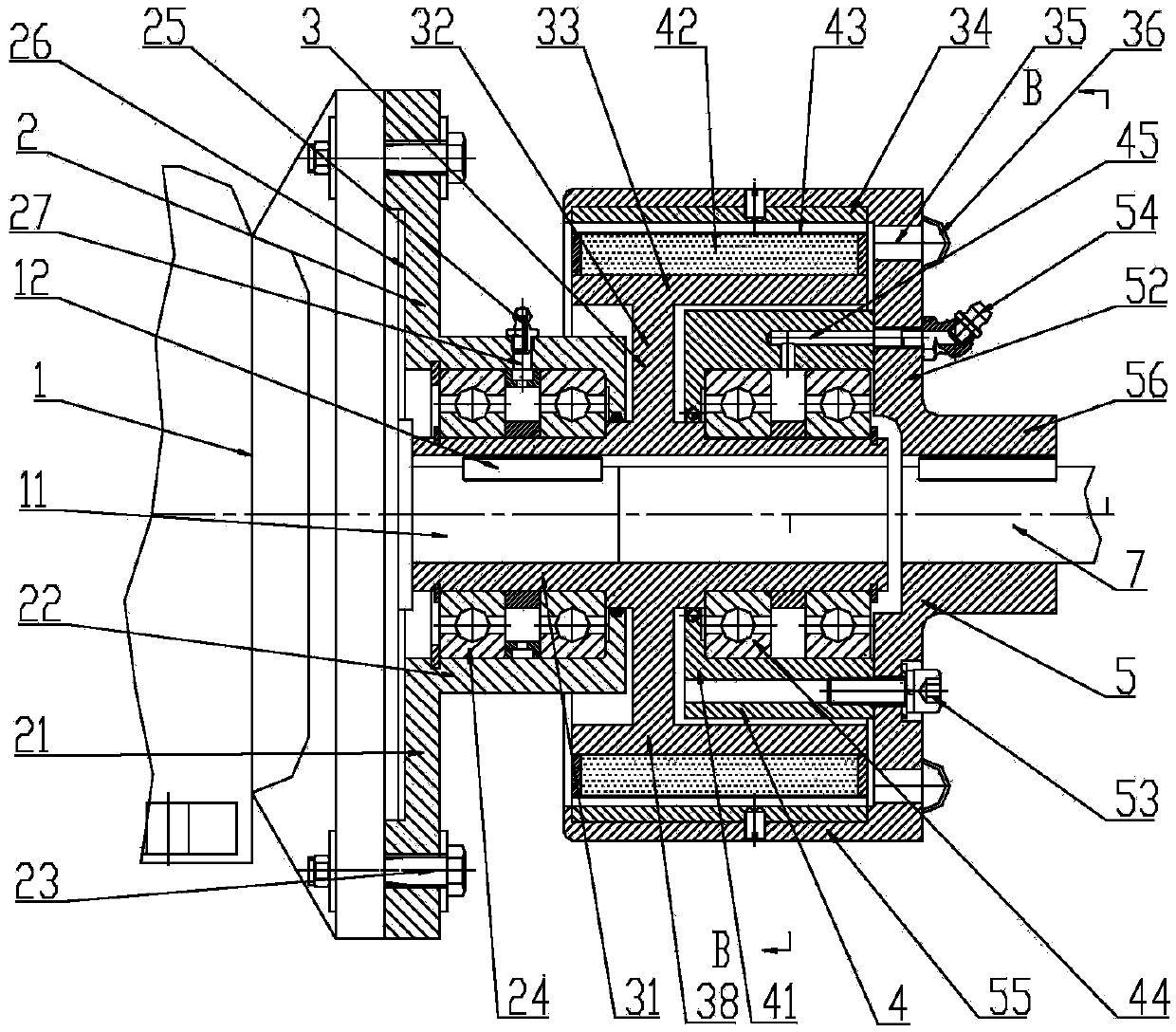

[0031] Such as image 3 , Figure 4 As shown in the figure, a coaxial sleeve type permanent magnet eddy current coupling with fixed end face includes a coaxial end face positioning seat 2, a driving rotor 3 and a driven rotor 4; the driving rotor 3 is used as an inner rotor, and the driving rotor body 38 and the permanent magnet layer 42 arranged on the active rotor body 38; the active rotor body 38 is composed of a hollow shaft 31, an outer liner 33 and a middle support plate 32, and the hollow shaft 31 is a cylindrical structure, which is arranged on the active The center of the rotor body 38; the middle support plate 32 is a disc-shaped structure, coaxially fixed in the middle of the outer wall of the hollow shaft 31; the outer lining 33 is a thin-walled cylindrical structure, made of magnetic material, fixed in the One side of the support plate 32, and the outer liner 33 is coaxially arranged with the hollow shaft 31; a keyway is provided on the inner side wall of the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com