Double-tray-type permanent magnet eddy-current coupler with fixed end surface

A permanent magnet eddy current, double-flat disc technology, applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of increased vibration and noise, inconvenient installation and operation, and reduced effective working life, so as to achieve stable operation and simplified operation. Effect of Installation Difficulty and Effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

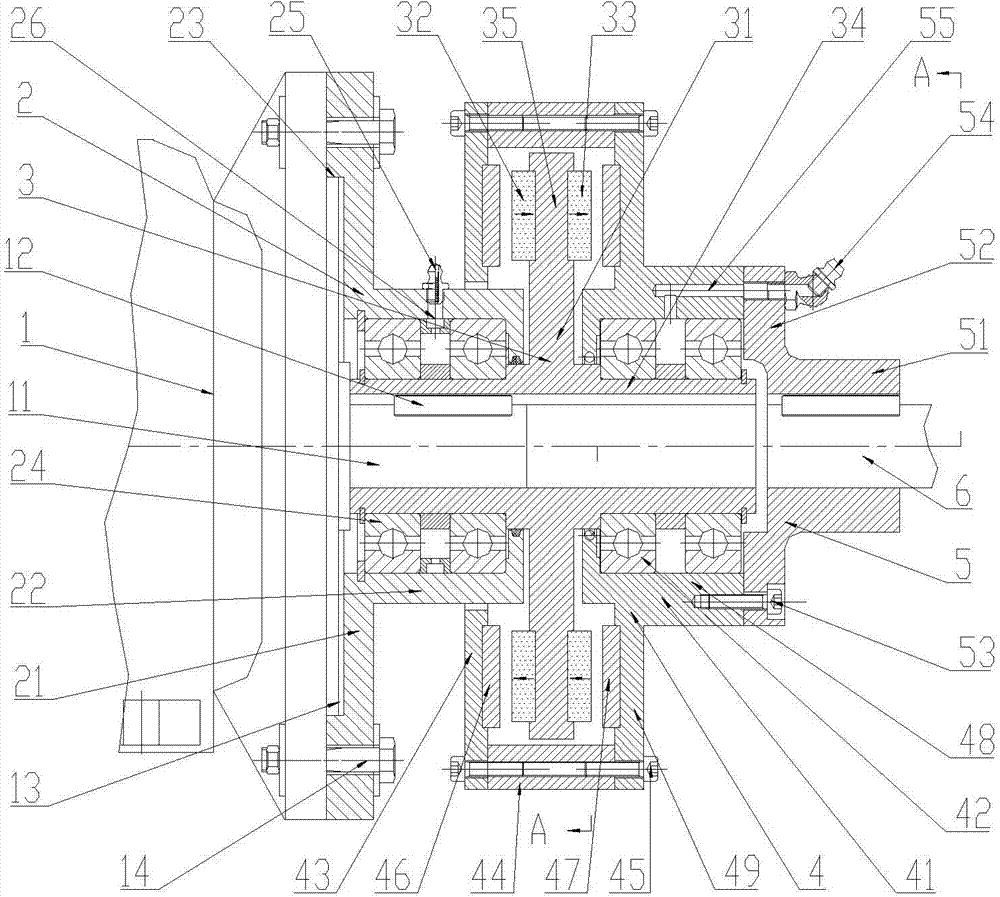

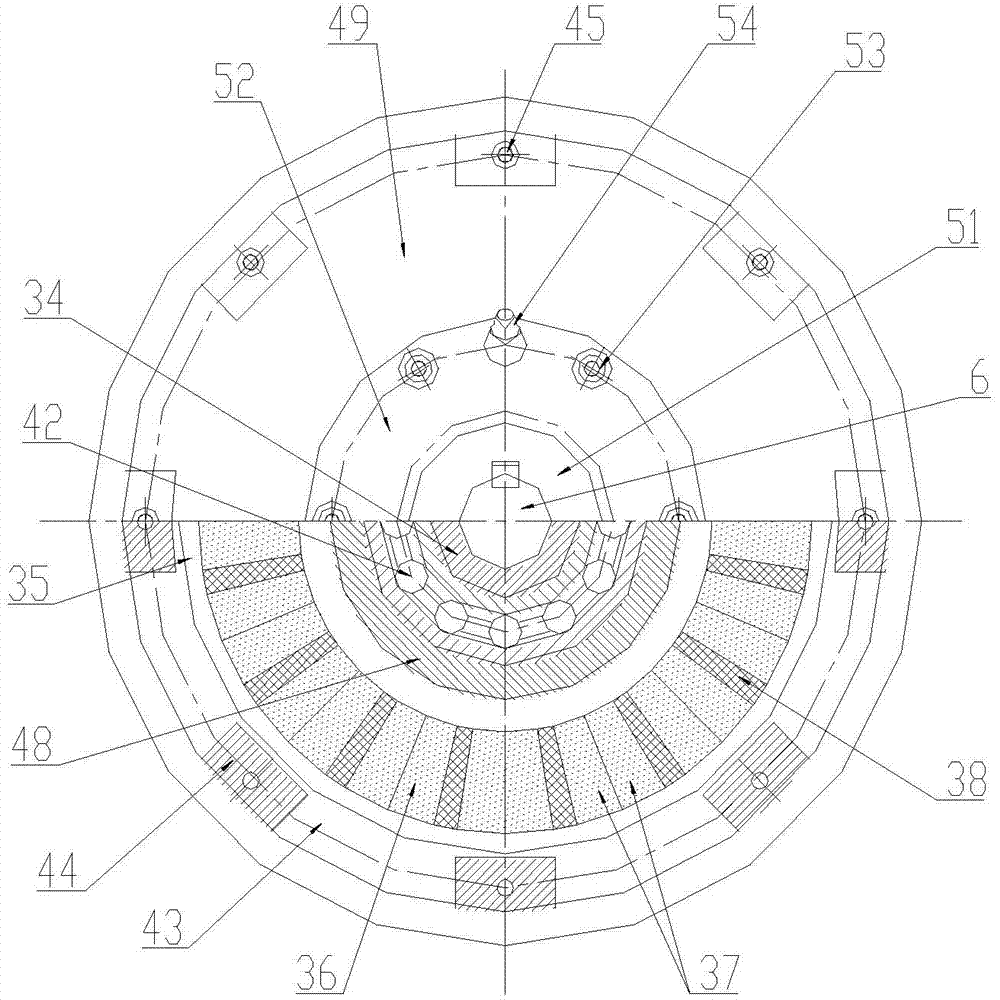

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] Such as figure 1 , figure 2 As shown, a double flat disc permanent magnet eddy current coupling with fixed end faces includes a coaxially arranged active rotor 3, a driven rotor 4, an end face positioning seat 2 and an end cover shaft 5; the active rotor 3 is composed of an active The rotor body 31, the inner permanent magnet layer 32 and the outer permanent magnet layer 33 are composed; the active rotor body 31 is composed of a coaxial cylindrical hollow shaft 34 and a disc-shaped middle support plate 35, and the hollow shaft 34 is arranged on the active At the center of the rotor body 31; a keyway is provided on the inner sidewall of the hollow shaft 34, which is used to cooperate with the motor shaft key 12 arranged on the motor shaft 11 of the B35 type motor 1, and the hollow shaft 34 is connected to the motor shaft 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com