Method for controlling automatic alloy feeding of converter steel ladle

A technology of automatic feeding and control method, applied in the field of automatic feeding control of converter ladle alloys, can solve the problems of difficult to standardize alloy feeding operation, high labor intensity, affecting the quality of tapping, etc., to overcome individual operation differences, reduce labor intensity, Universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

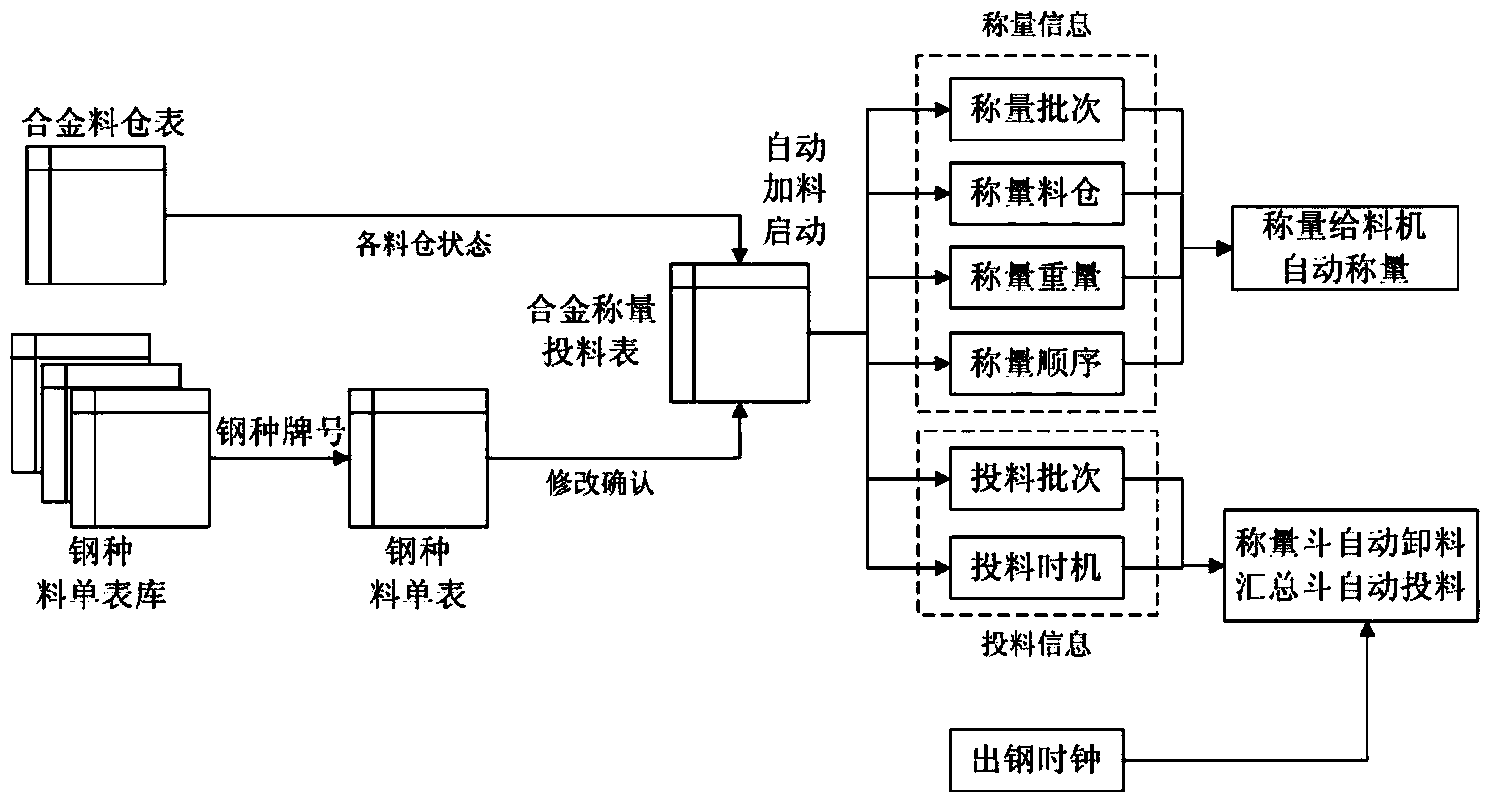

[0037] figure 1 It is a control flow chart of a kind of converter ladle alloy automatic feeding control method of the present invention, as figure 1 As shown, the method mainly includes:

[0038] Step 1: Establish the alloy silo table and steel material bill table database;

[0039] Step 2: Select the corresponding steel bill of materials according to the steel grade, modify and confirm, and issue an alloy automatic feeding start command, and automatically generate each material batch in the alloy weighing and feeding table by combining the steel bill of material and the alloy bin table Weighing information and feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com