Bridge integrated cast-in-place anti-collision guardrail and special formwork for hanging board and its construction method

An anti-collision guardrail, an integrated technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of bottom formwork damage, poor formwork safety, short service life, etc., to ensure construction quality and safety, and ensure safety The effect of durability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

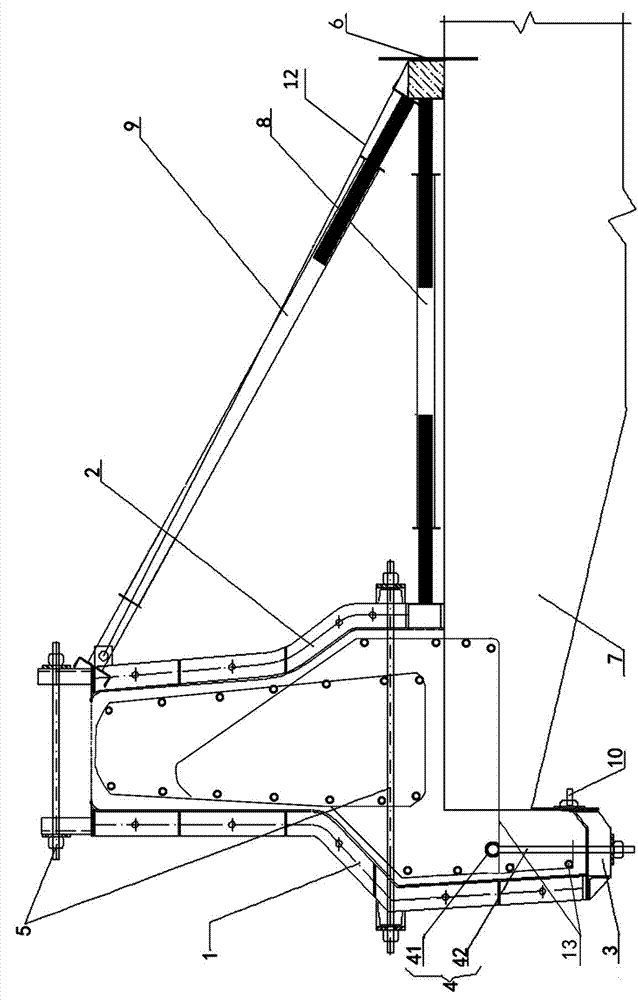

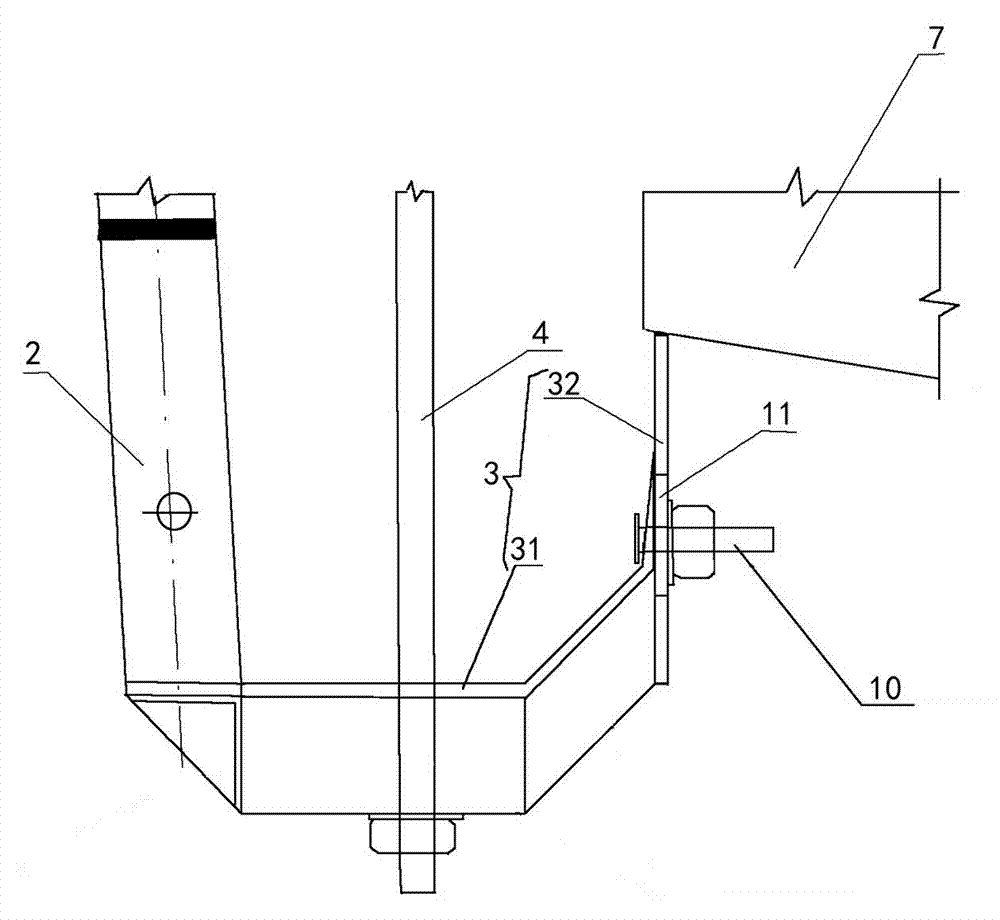

[0038]This embodiment is the overall design of the overpass anti-collision guardrail and hanging plate. The anti-collision guardrail is 1.013m high, the upper opening is 0.3m wide, and the lower opening is 0.678m wide. The hanging plate below the bridge wing plate is 0.53m high and 0.2m wide. The total length is 8211 linear meters. combined with Figure 1~4 , as shown in the figure, a bridge integrated cast-in-place anti-collision barrier and special formwork for hanging panels, including an outer formwork 1 extending along the direction of the bridge deck, an inner formwork 2 and a bottom formwork 3, the inner formwork 2 is set on the bridge wing The surface of the board 7 is fixed by a support system, which includes horizontal braces 8 and diagonal braces 9 fixed by ground anchors 6, and the ground anchors 6 are Φ25 steel bars pre-buried at intervals of 2m; the outer formwork 1 is suspended on The outer side of the bridge wing plate 7 is longer than the inner formwork 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com