A ballast water system with pipe section settling

A technology of ballast water and ballast water tanks, which is applied in construction, infrastructure engineering, etc., can solve the problems of high precision and difficulty in settlement, and achieve the goals of improving construction precision of settlement, lightening load, rapid water injection and drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

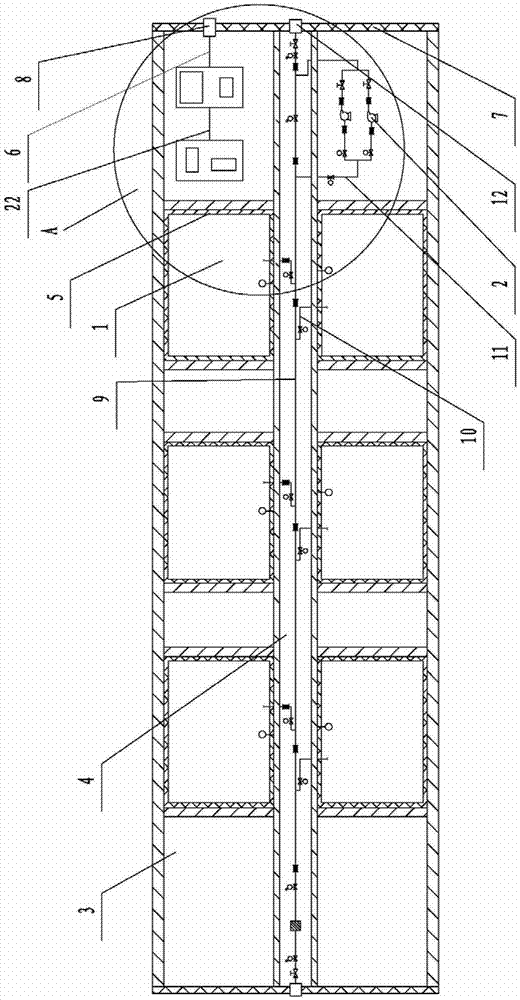

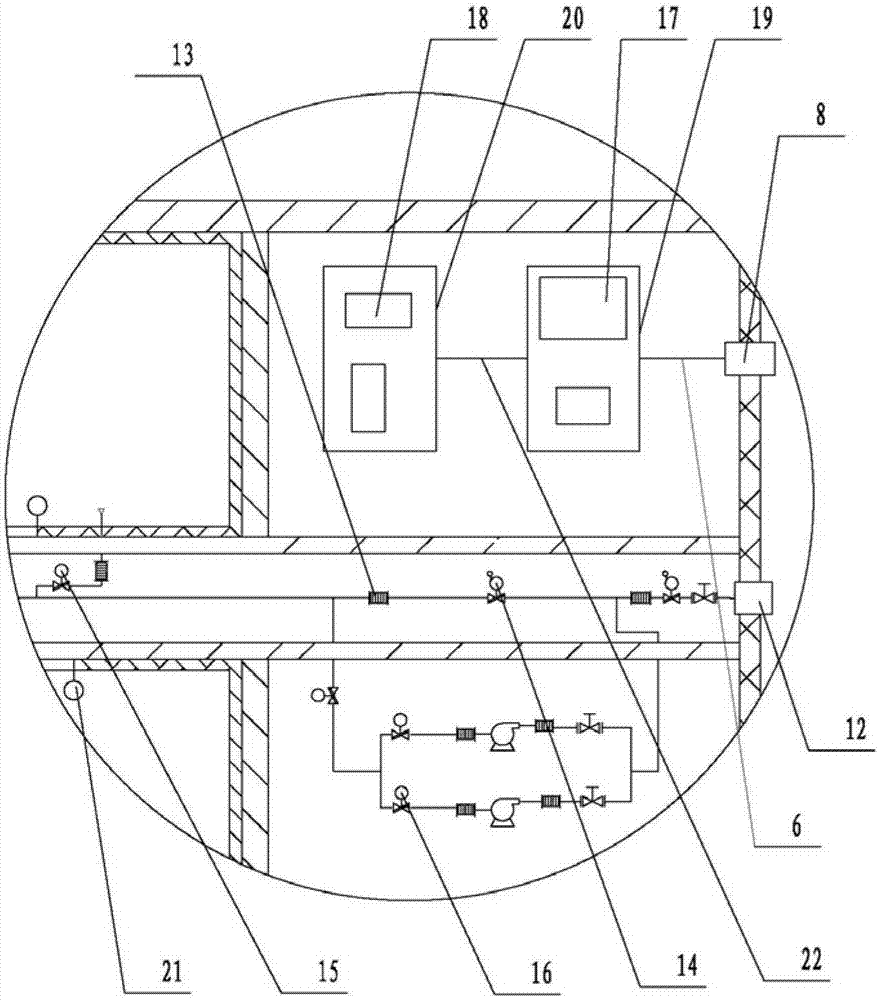

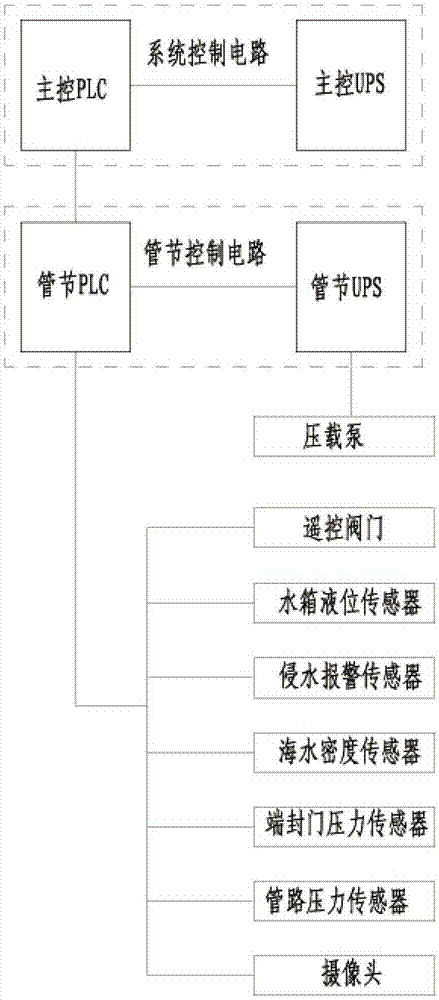

[0021] see figure 1 , figure 2 , image 3 As shown, the ballast water system for sinking pipe joints in this embodiment includes a system control circuit for issuing control commands, a pipe joint control circuit for forwarding control commands, and six ballast water storage systems. A ballast water tank 1 and two ballast pumps 2 for discharging ballast water, one of which is in regular use and the other ballast pump is used as a backup; the size of the ballast water tank described in this embodiment is 20m×14.5m×5.0 m.

[0022] The system control circuit described in this embodiment is arranged on the installation ship (belonging to the prior art, not shown in the figure), and the pipe joint control circuit, ballast water tank and ballast pump are arranged in the inner cavity 3 of the pipe joint to be sunk. . In order to facilitate construction (the GINA end needs to be docked with the installed pipe section, and no cables should exist), the pipe section control circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com