A fully automatic spring roll wrapping machine

A spring roll making, fully automatic technology, applied in the field of spring roll machine, can solve the problems of low production efficiency, high manufacturing cost, unprofessional spring roll wrapping process, etc., and achieve the effect of convenient operation, high production efficiency and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

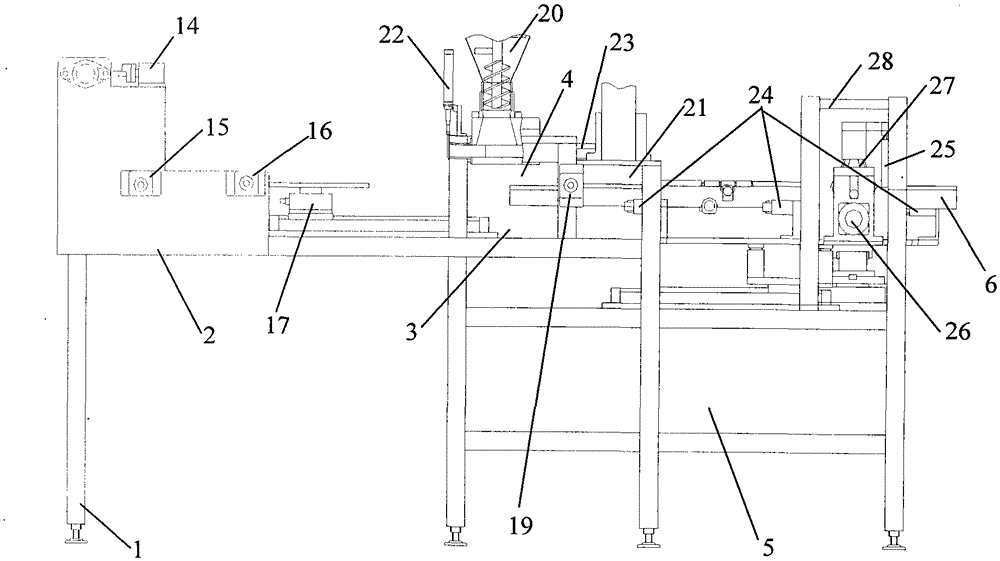

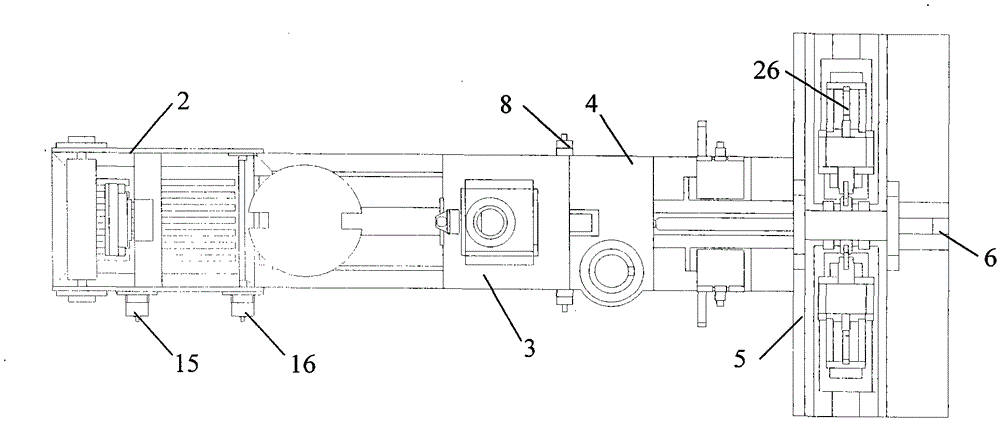

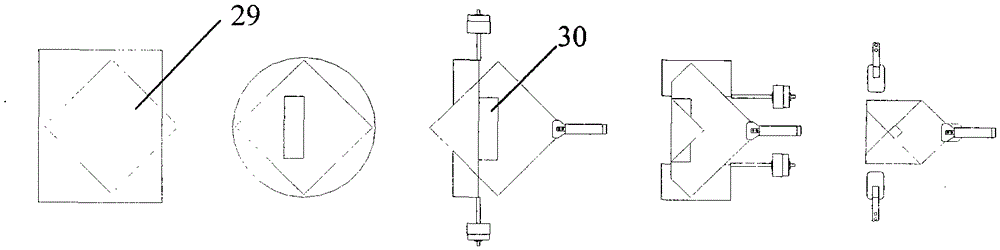

[0013] The present invention will be further explained below in conjunction with accompanying drawing.

[0014] In the figure, 1. Rack, 2. Leather making mechanism, 3. Rotary table, 4. Stuffing mechanism, 5. Encapsulation mechanism, 6. Transmission mechanism, 7. Beater, 8. Dough forming device, 9. Conveying Device, 10, cooling device, 11, cutter, 12, dry noodle bucket, 13, overturn counting device, 14, rotary cylinder A, 15, rotary cylinder B, 16, rotary cylinder C, 17, rotary cylinder D, 18, Standard cylinder A, 19, swing cylinder, 20, stuffing hopper, 21, stuffing mechanism, 22, standard cylinder B, 23, double cylinder A, 24, pneumatic finger cylinder, 25, double cylinder B, 26, standard Cylinder C, 27, jack manipulator, 28, shell, 29, dough, 30, stuffing.

[0015] Such as figure 1 , figure 2 , Figure 4 As shown, the leather making mechanism 2, the rotary table 3, the cladding mechanism 5, and the transmission mechanism 6 are sequentially connected and arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com