Shredder Delay Mechanism Integrating Power-off Safety Switch Function of Machine Head

A technology of safety switch and time-delay mechanism, which is applied in the direction of grain processing, etc., can solve the problems of increasing manufacturing costs and increasing the number of shredder parts, and achieve the effects of convenient and efficient use, cost saving, and guaranteed time-delay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

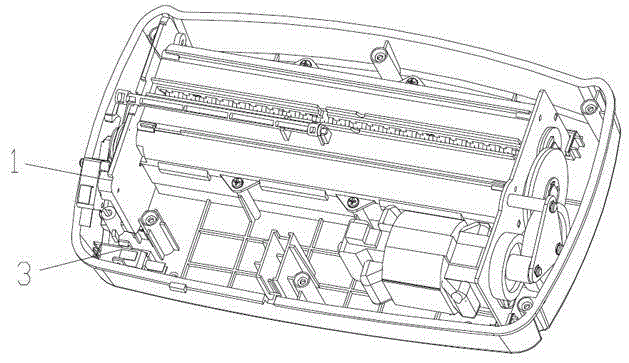

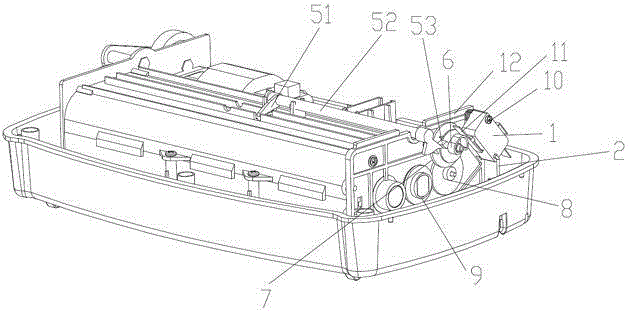

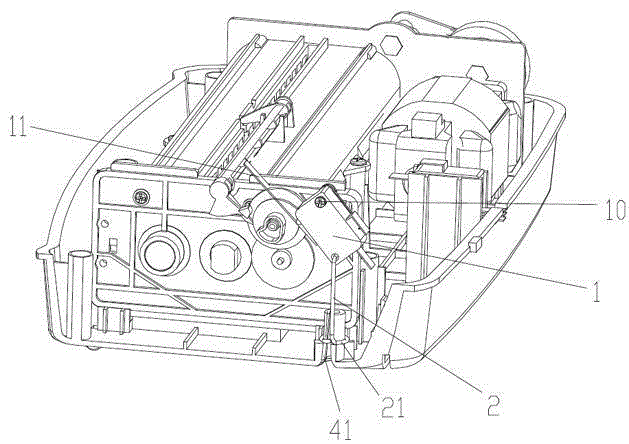

[0022] see figure 2 The shredder time-delay mechanism integrating the power-off safety switch function of the machine head in this embodiment includes a time-delay switch body 1, and the time-delay switch body 1 is pivotally connected to the side plate 12 of the paper shredder through a connecting shaft 10. The time-delay switch body 1 is connected with a stress rod 2, and the paper shredder waste paper barrel is provided with a supporting rib 31 at a position corresponding to the stress rod 2 ( figure 2 not shown, see Figure 4-8 ), one end of the force rod 2 is pivotally connected to the delay switch body 1, and the other end is connected to the supporting rib 31 ( figure 2 not shown, see Figure 4-8 ) contact connection, the force bar 2 can push the delay switch body 1 to rotate under the push of the support rib 31 when the head of the shredder is put into the waste paper bin, so that it is in the paper-feeding touch state. In this embodiment, the delay switch body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com