Slurry tank scraper

A slurry, horizontal expansion and contraction technology, applied in chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of corporate waste, troublesome scraping, and difficult to clean jars, achieving immediate results and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

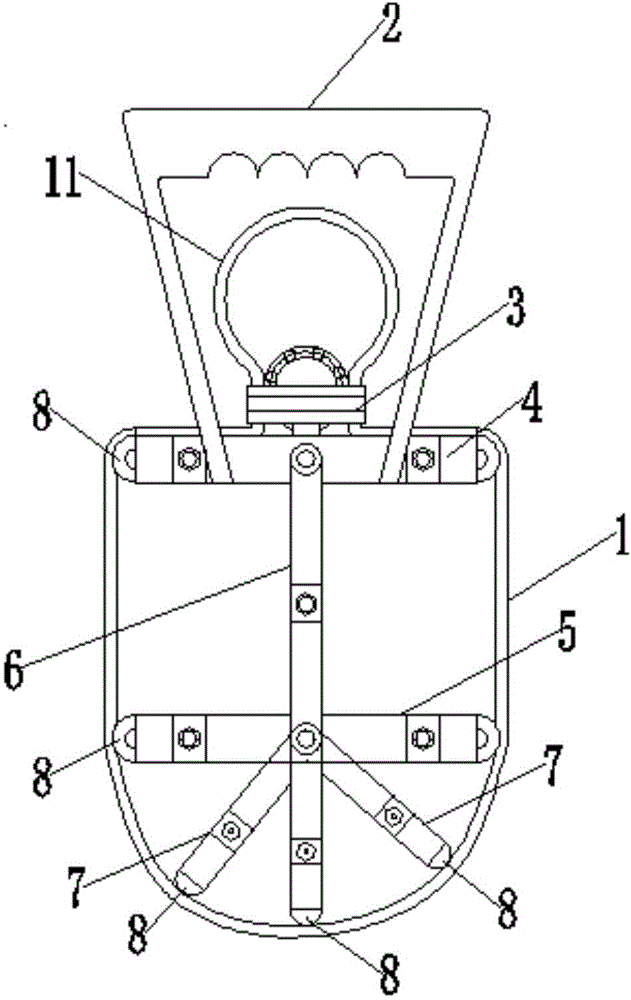

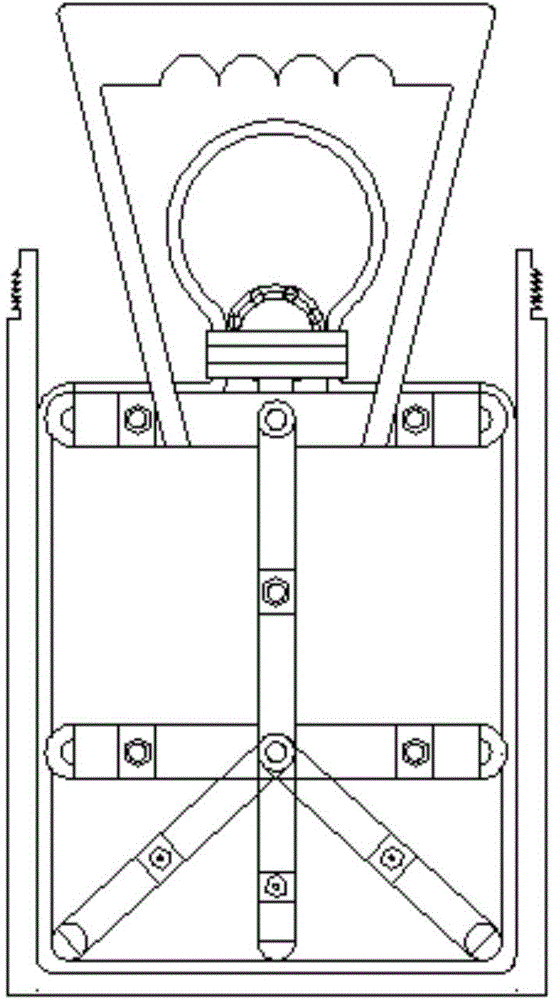

[0013] Embodiment: a kind of slurry tank scraper, such as figure 1 As shown, it includes a rubber ring 1, a handle 2, a fixed plate 3, a first horizontal telescopic rod 4, a second horizontal telescopic rod 5, a longitudinal telescopic rod 6 and two rotation positioning telescopic rods 7, and the first lateral telescopic rod , the second horizontal telescopic rod, the vertical telescopic rod and the two rotary positioning telescopic rods are all rods whose length can be stretched and fixed, and the first horizontal telescopic rod and the second horizontal telescopic rod are in a vertically parallel positional relationship, The first horizontal telescopic rod is fixedly connected to the upper end of the longitudinal telescopic rod at its middle and is perpendicular to the longitudinal telescopic rod, and the second horizontal telescopic rod is fixedly connected to the middle of the longitudinal telescopic rod at its middle and perpendicular to the longitudinal telescopic rods, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com