A method for designing yarn twist and fabric tightness in colored weaving

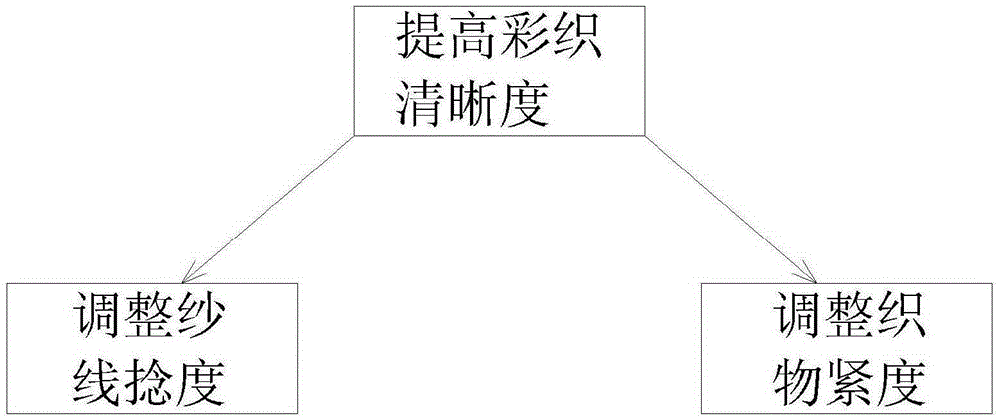

A technology of fabric tightness and fabric, applied in the direction of fabrics, textiles, papermaking, yarn, etc., can solve the problems of simulated picture interference, inability to solve, and inability to weave with clear photos, and achieve the effect of improving picture clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Using pure landscape original photos, using compact spinning cotton yarn, the yarn twist is 100 (twist / 10cm), the warp tightness Et and weft tightness Ew are 47, the total fabric tightness is 93.78, and the color weaving sample The size is 60x90 cm, the warp density is 250 (root / 10cm), the weft density is 280 (root / 10cm), and the fabric sample picture is highly simulated.

Embodiment 2

[0053] Using the original photos of the coexistence of people and scenery, the theme of colorful weaving is landscape, using compact spun cotton yarn, the yarn twist is 100 (twist / 10cm), the warp tightness Et and weft tightness Ew are 47, the total fabric The tightness is 93.78, the size of the color-woven fabric sample is 60x90 cm, the warp density is 250 (root / 10cm), and the weft density is 280 (root / 10cm). The people in the foreground appear sandy and blurred, and the landscape part is highly simulated.

Embodiment 3

[0055] Use the original photo with the coexistence of people and scenery, and the characters occupy more than 80% of the area. The theme of colored weaving is expressed as characters. Pure polyester yarn is used. The twist of the yarn is 120 (twist / 10cm), and the warp tightness Et and weft tightness The Ew is 49, the overall tightness of the fabric is 97.04, the color woven fabric sample size is 60x90 cm, the warp density is 960 (roots / 10cm), the weft density is 980 (roots / 10cm), the close-up characters are highly simulated, and the landscape part as the background is due to the yarn The texture is flat and shallow, slightly fuzzy.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap