A Robust Design Method for Technical Parameters of Automobile Chassis Based on Full Life Cycle

A full life cycle, automotive chassis technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve problems such as products that cannot be guaranteed, and achieve the effect of ensuring optimality, optimal performance and robust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

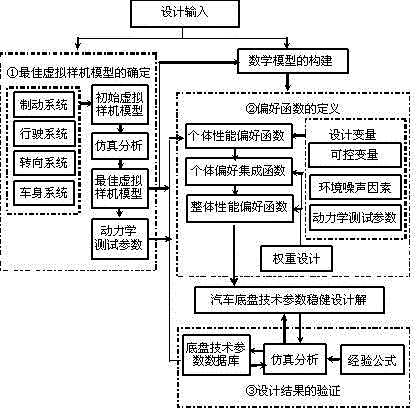

[0017] The best implementation mode of the present invention will be described below in conjunction with the accompanying drawings.

[0018] 1. Design Entry

[0019] First input the basic parameters of the vehicle, mainly including the wheelbase, wheel base, kingpin center distance, load, position of the center of mass, main parameters of the tires, and chassis technical parameters: steering mechanism, driving system, braking system Initial value and definition domain, noise factors in automobile use: load, braking force, initial value and definition domain of steering torque, etc.

[0020] 2. Determine the best virtual prototyping model

[0021] Based on the input basic parameters of the whole vehicle, the assembly of the steering system, braking system, driving system and other modules is automatically completed by using the parametric virtual prototype model. The modules are divided as follows

[0022] serial number module name Submodule code structure typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com