A kind of automobile shifter assembly

An automobile gear shifting and assembly technology, which is applied in the direction of pivot connection, toothed components, belt/chain/gear, etc., can solve the problems of cable deformation, gear adjustment accuracy reduction, etc., to reduce noise and Effect of small shift gap, avoidance of shift gap and control lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

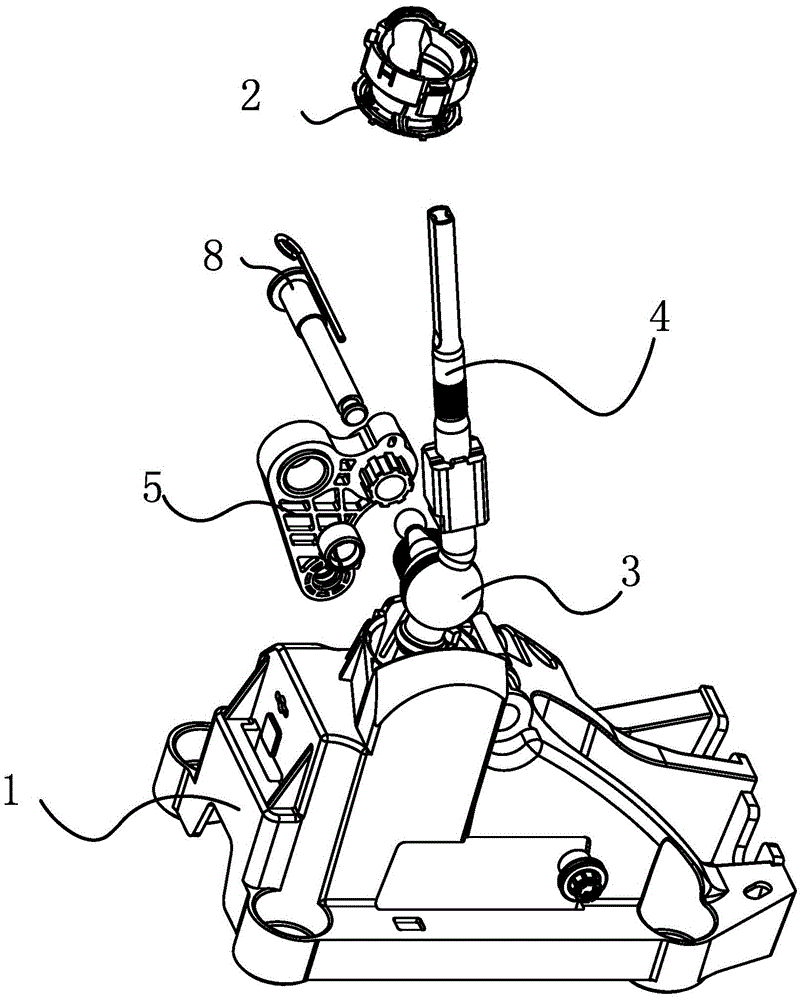

[0036] Please refer to figure 1 , in one embodiment of the present invention, the automobile shifter assembly includes a base 1, a cover ring 2, a rotating center ball 3, an operating rod 4 and a gear selection arm 5, and the base 1 is provided with a first shaft hole 10 and Ball seat hole 11, the gear selection arm 5 is provided with a second shaft hole 50 and a spherical shaft hole 51, the rotating center ball 3 is fixed with a first spherical pin 30, and the cover ring 2 is fitted in the ball seat hole 11, the rotating center ball 3 is rotatably installed in the cover ring 2, the operating rod 4 is longitudinally fixedly connected to the rotating center ball 3, and the gear selection arm 5 passes through the spherical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com