Automatic stoking and deslagging device for curing barn heating device

A heating equipment, automatic technology, applied in lighting and heating equipment, combustion equipment, tobacco preparation and other directions, can solve the problems of economic loss, high labor intensity, complex production management, etc., to save production and operation costs, improve combustion rate , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

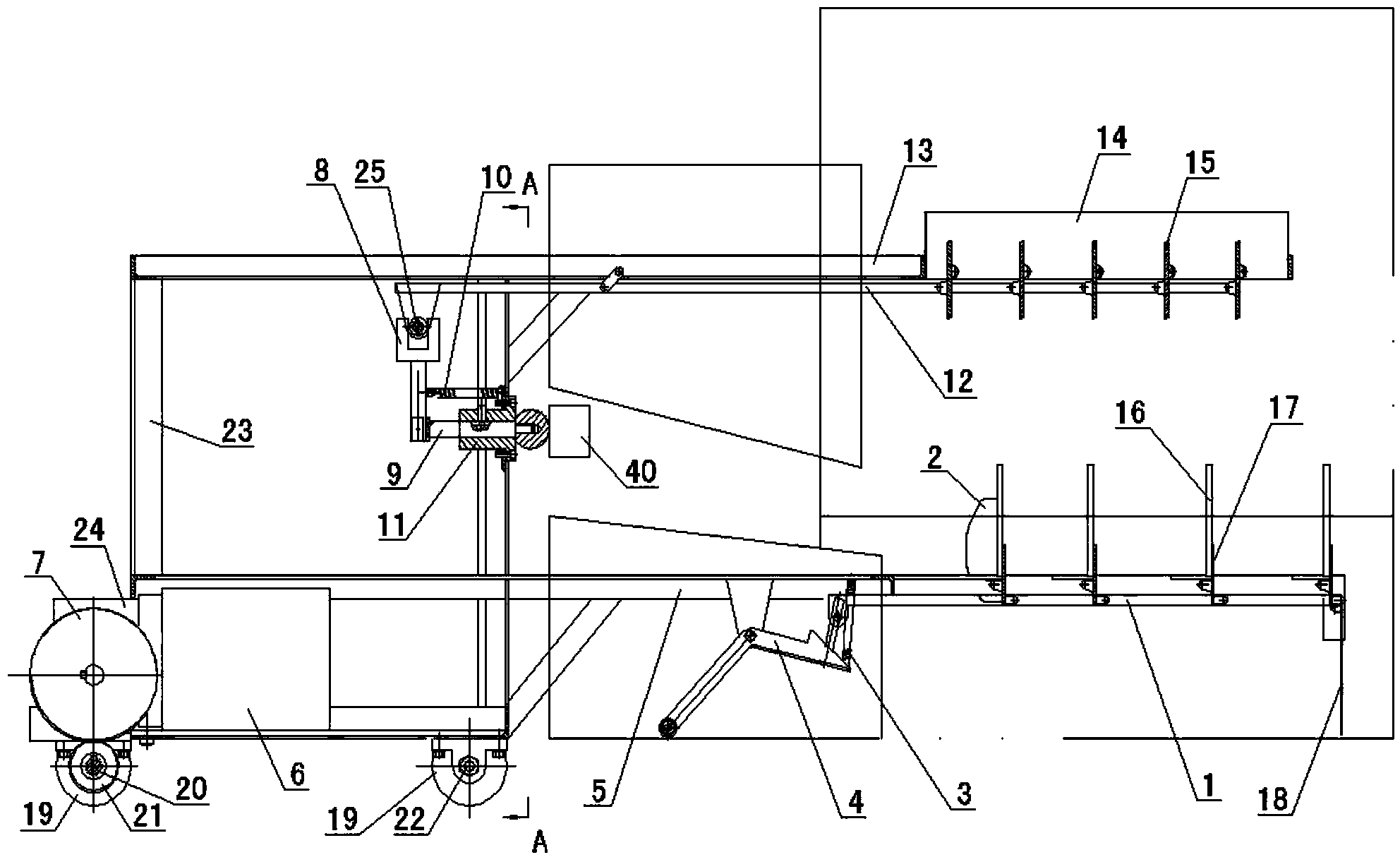

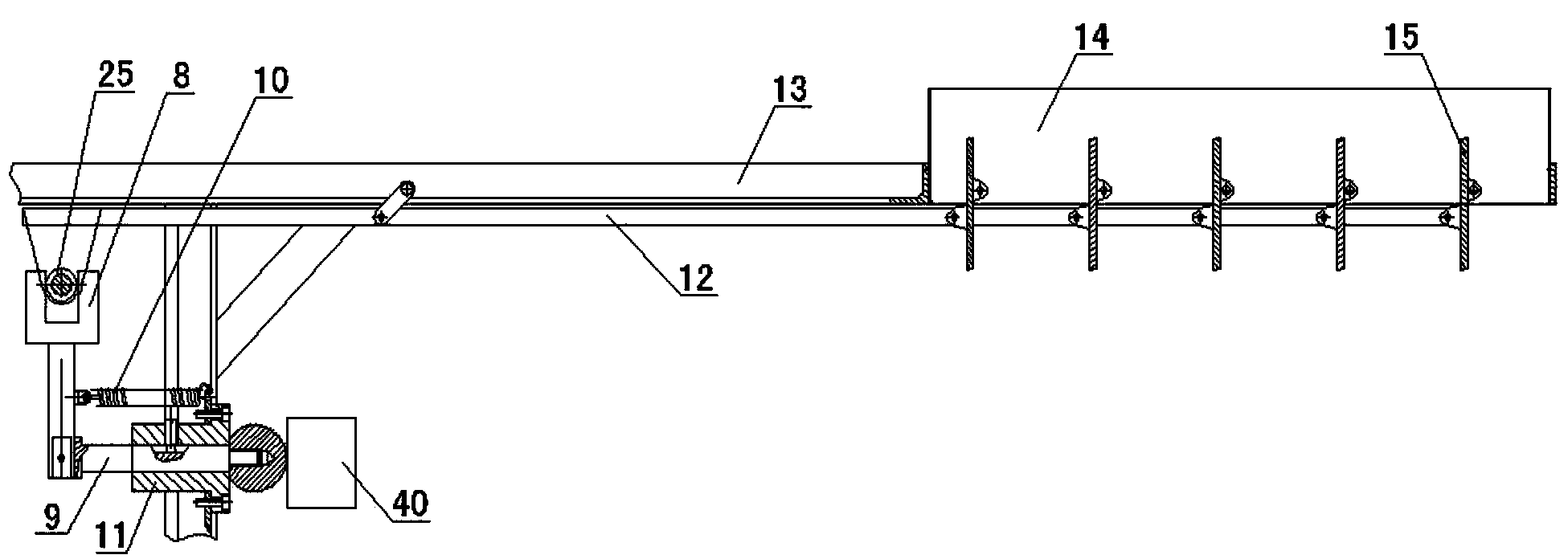

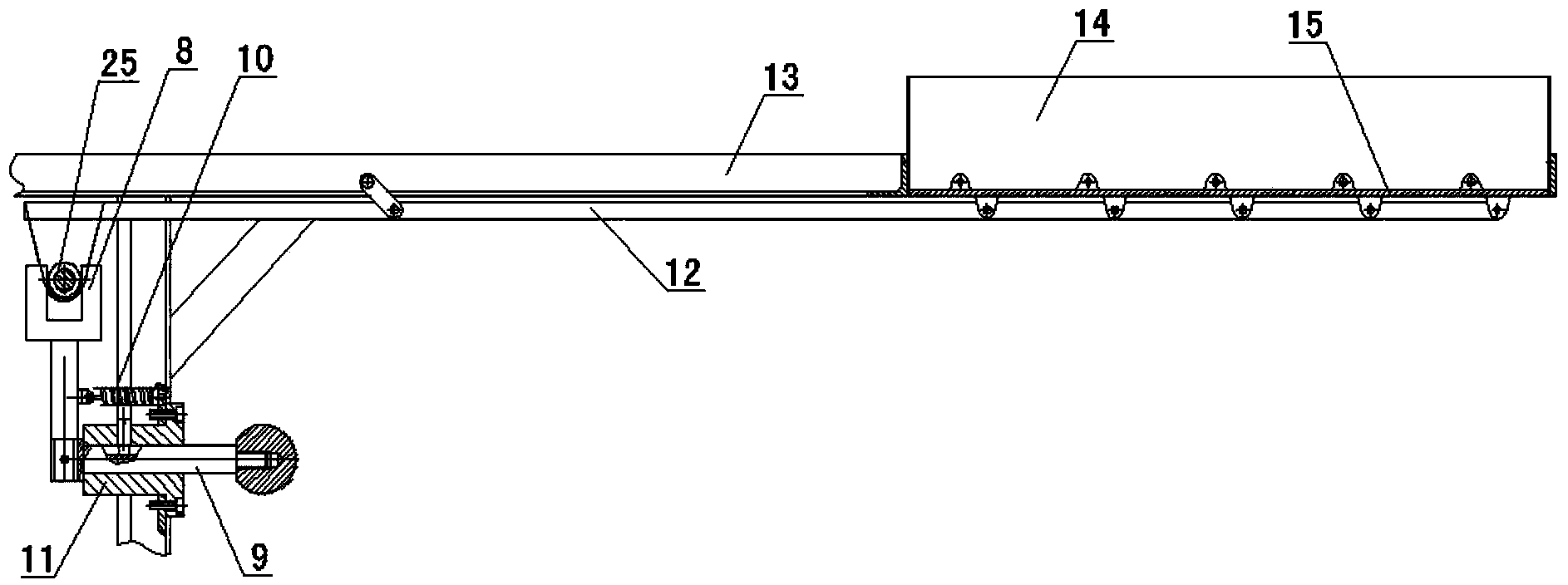

[0034] The structural form of the automatic coal addition and slag removal device for the heating equipment of the barn in this embodiment is:

[0035] see figure 1 and figure 2 and image 3 , automatic coal delivery and slag removal trolley is set in the present embodiment, and its vehicle frame 23 adopts three-layer structure, is respectively vehicle frame upper layer, vehicle frame middle layer and vehicle frame bottom layer; Coal box 14 is arranged between, each coal box bottom blade 15 that can rotate in vertical plane is set at the bottom of coal box 14; Each claw plate 17 that rotates in the vertical plane is provided with each loose coal rake ash claw 16 at intervals on the claw plate 17; Dust scraper 18 is provided with track wheels 19 at the bottom of the vehicle frame.

[0036] see Figure 4 and 4a , a storage and falling coal machine is set, and coal scuttle 29 is set on the top of a storage and falling coal frame 27, and coal scuttle bottom plate 32 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com