A kind of self-adjusting steam seal and its installation and debugging method

A technology for installation, commissioning and steam sealing, applied in the field of steam turbine steam seals, can solve the problems affecting the enthusiasm of steam seal renovation in power plants, the sealing performance is not significantly improved, and the steam turbine rotor is heated too quickly, so as to reduce the loss of start-up and shutdown and improve the sealing performance. , good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

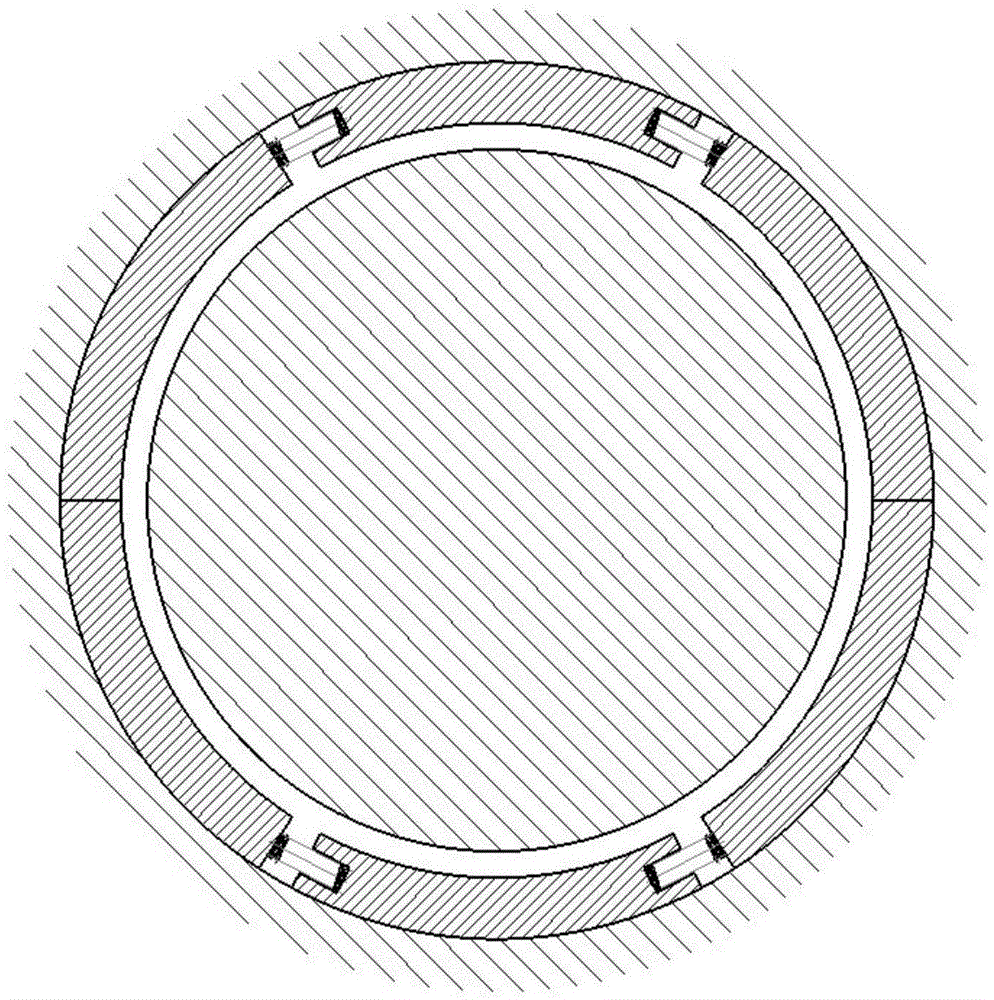

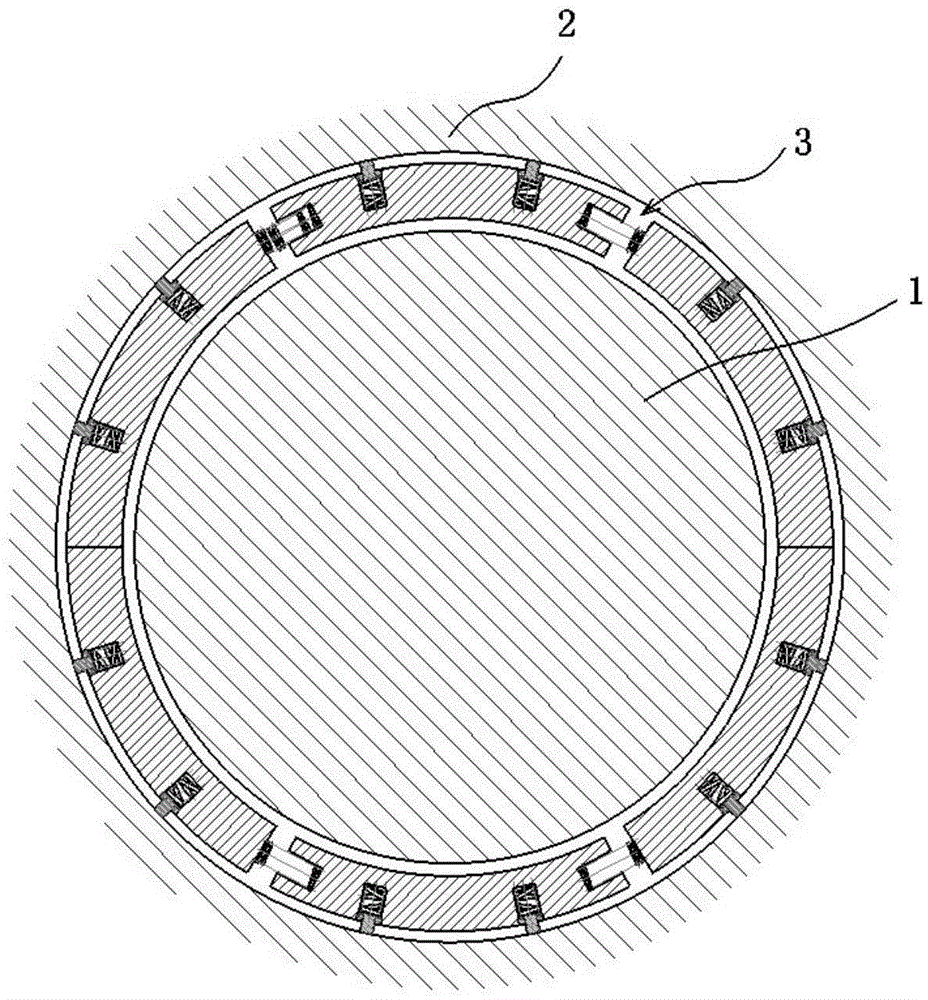

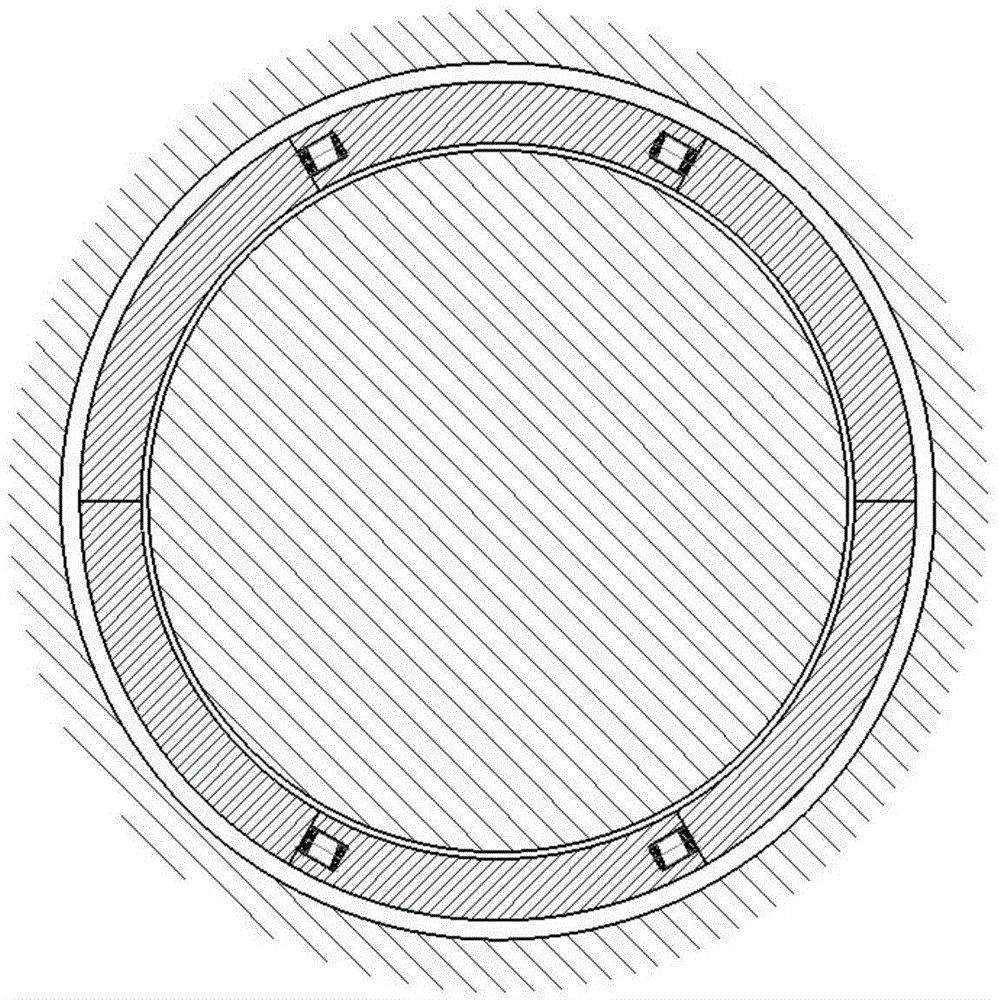

[0074] Such as Figure 1-17 The self-tuning seal shown in the figure includes seal arcs and circumferential springs arranged between the seal arcs, and a radial spring assembly is arranged on the outside of the seal arcs;

[0075] The large back arc of the steam seal arc section is provided with a mounting hole for installing a radial spring assembly, and the radial spring assembly is located in the mounting hole and is higher than the large back arc;

[0076] The radial spring assembly includes a radial spring, a radial protruding rod and a gland; the radial spring is arranged in the mounting hole; the gland is threaded on the inner wall of the mounting hole; The gland is engaged in the installation hole and pressed on the radial spring, the ejector rod passes through the gland and can slide relative to the gland, and the ejector rod is higher than the large back arc.

[0077] There is riveting between the gland and the arc section of the steam seal, the outer end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com