An anti-out gear seat synchronizer

A synchronizer and anti-shift technology, which is applied to clutches, mechanically driven clutches, mechanical equipment, etc., can solve problems such as shifting, and achieve the effects of simple structure, avoiding shifting, and ensuring normal meshing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

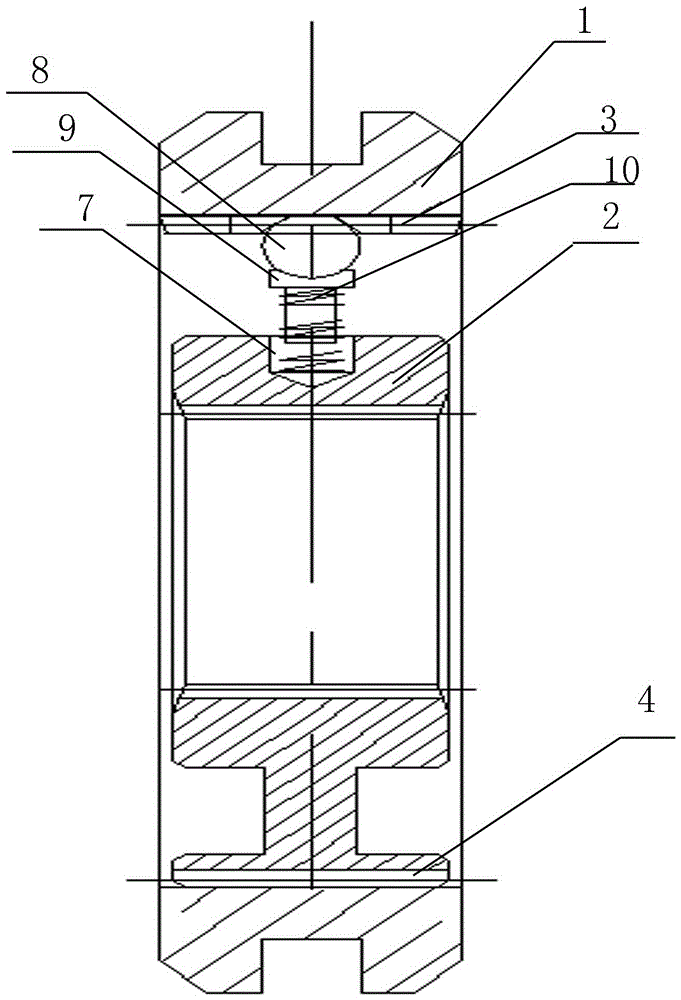

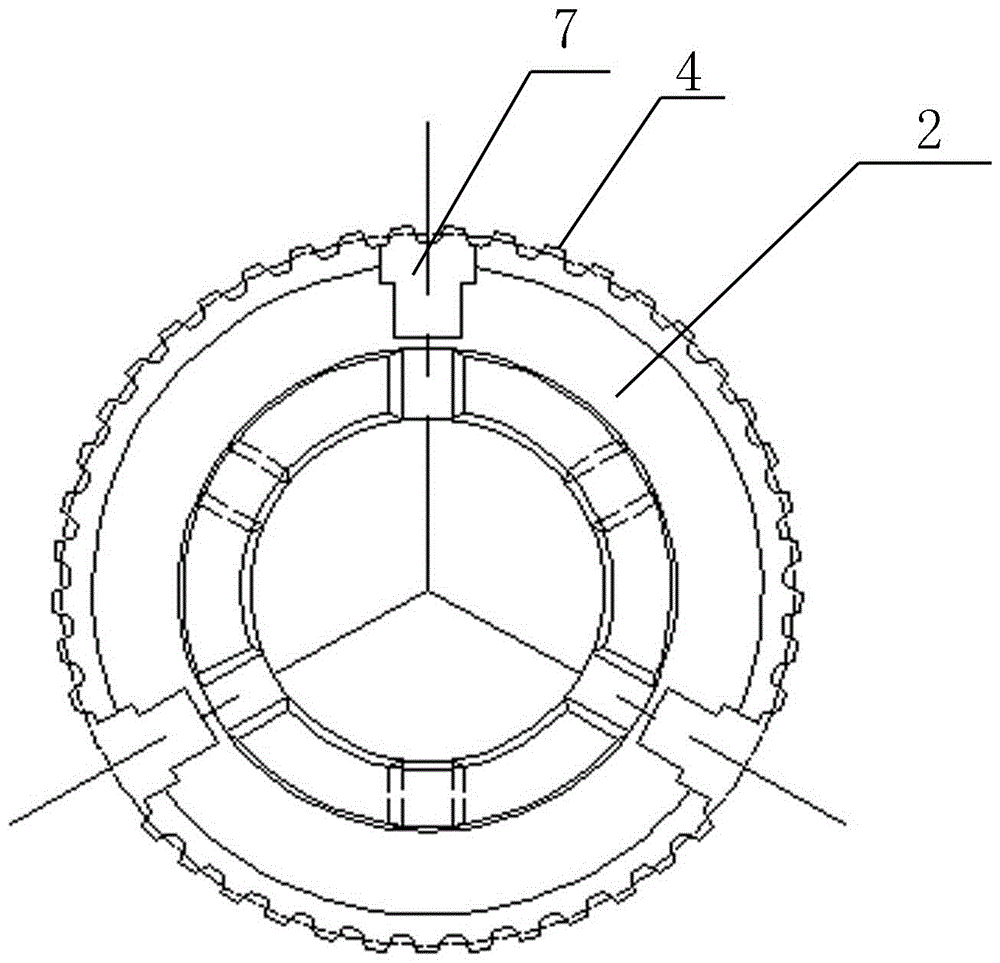

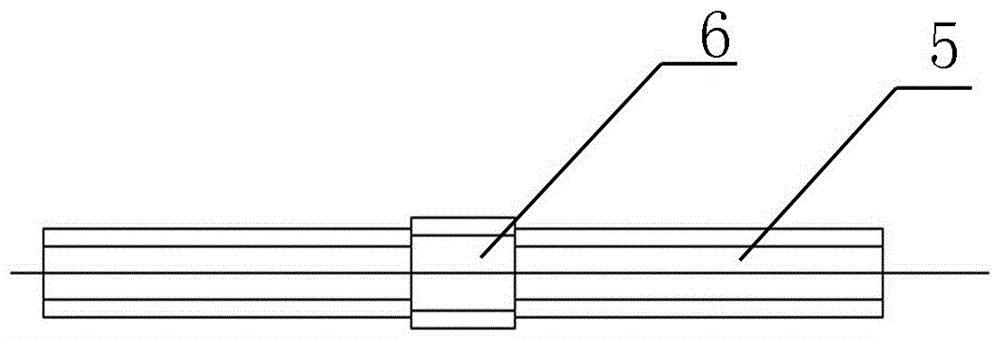

[0010] exist figure 1 , figure 2 and image 3 Among them, the present invention provides a kind of anti-shift gear seat synchronizer, which includes a synchronous sliding sleeve 1 and a synchronous tooth seat 2, the inner wall of the synchronous sliding sleeve 1 is provided with an internal spline 3, and the synchronous tooth seat 2. An external spline 4 is provided on the upper outer surface, and the synchronous sliding sleeve 1 and the synchronous tooth seat 2 are connected to each other through the cooperation of the internal spline 3 and the external spline 4. The outer diameter of the external spline 4 of the synchronous tooth seat 2 is the same as The inner diameter of the inner spline 3 of the synchronous sliding sleeve 1 is matched, the middle part of the outer spline 4 of the synchronous tooth seat 2 is thick teeth 6, and the two ends are thin teeth 5. The thick tooth 6 meshes with the internal teeth of the internal spline 3 of the synchronous sliding sleeve 1. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com