Forming method of 90 degree straight pier thickening and thickening bent pipe

A forming method and pipe bending technology, which is applied in the field of 90-degree straight section thickening and thickening pipe bending forming method to achieve the effects of reliable quality, saving foreign exchange expenditure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention relates to a method for forming a 90-degree straight pier thickening and thickening bent pipe. The forming method includes the following steps:

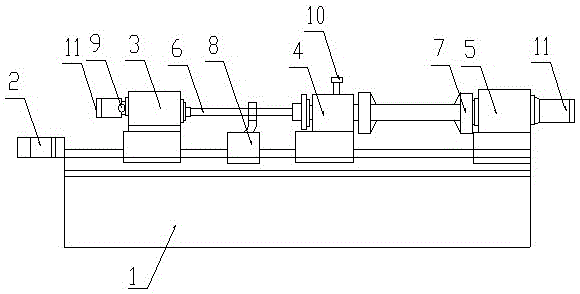

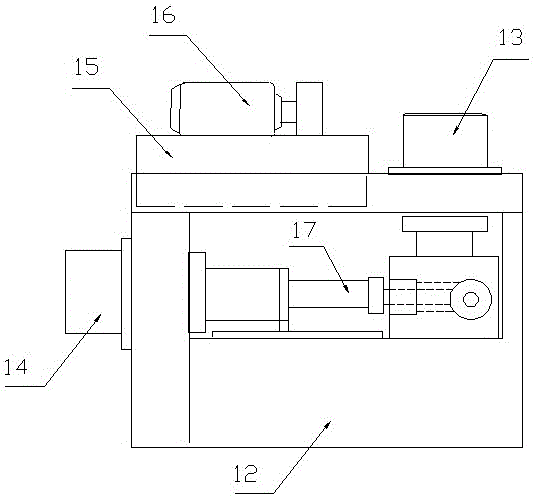

[0039] Step 1. Carry out the perforation process on the selected round steel with a diameter of 160mm and a length of more than 1m. Since the length of the round steel is long and the hole diameter is small, the perforation diameter is 76mm. General machine tools cannot be used for perforation. punching machine, such as figure 1 As shown, the perforating machine includes a bed 1, a feed motor 2 is arranged at one end of the bed 1, and a movable milling head 3, a fixed support 4 and a fixed milling head are sequentially arranged on the bed 1 5. A driving motor 11 is connected to the movable milling head 3 and the fixed milling head 5, a drill rod 6 is connected to the movable milling head 3, and the round steel to be processed is set on the fixed milling head 5 through the chuck 7 Above, the drill rod 6 and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com