Inner and outer double-tube self-supporting self-adaptive anti-vibration steel chimney

An adaptive, self-supporting technology that can be used in building components, building types, earthquake resistance, etc., to solve problems such as no effect and reduce wind vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

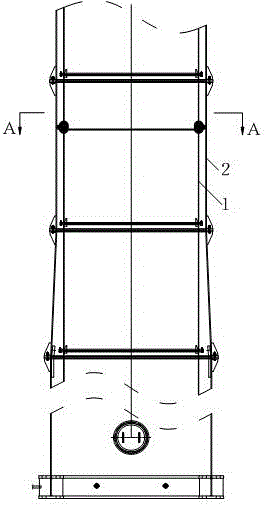

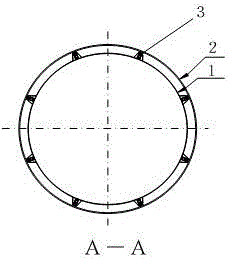

[0017] like figure 1 As shown in the figure, the inner and outer double-tube self-supporting self-supporting self-supporting anti-vibration steel chimney includes a self-supporting inner tube 1 and a self-supporting outer tube 2 sleeved outside it, such as figure 2 As shown, a plurality of frequency modulation anti-shake spring devices 3 are installed at the cross-sectional positions of different heights between the self-supporting inner cylinder 1 and the self-supporting outer cylinder 2, and the plurality of frequency modulation anti-shake spring devices 3 at the same cross-sectional position are along the circumferential direction. It is evenly distributed; the self-supporting inner cylinder 1 is connected with the self-supporting outer cylinder 2 through the frequency modulation anti-sway spring device 3 .

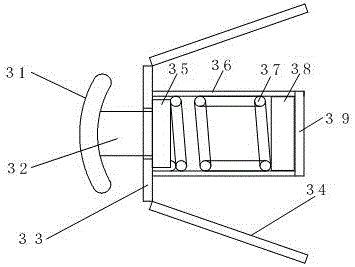

[0018] like image 3 As shown, the FM anti-shake spring device includes a sleeve 36 and a push rod 32. One end of the sleeve 36 is installed with a fixed plate 33, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com