Rolling door with adjustable spring torque

A technology for adjusting springs and rolling doors, applied to windows/doors, door/window protection devices, shutters/movable grilles, etc., can solve the problems of rolling door spring fatigue, inconvenient use, and difficult adjustment of rolling door springs, etc. , to achieve good locking effect, easy adjustment, and convenient spring torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

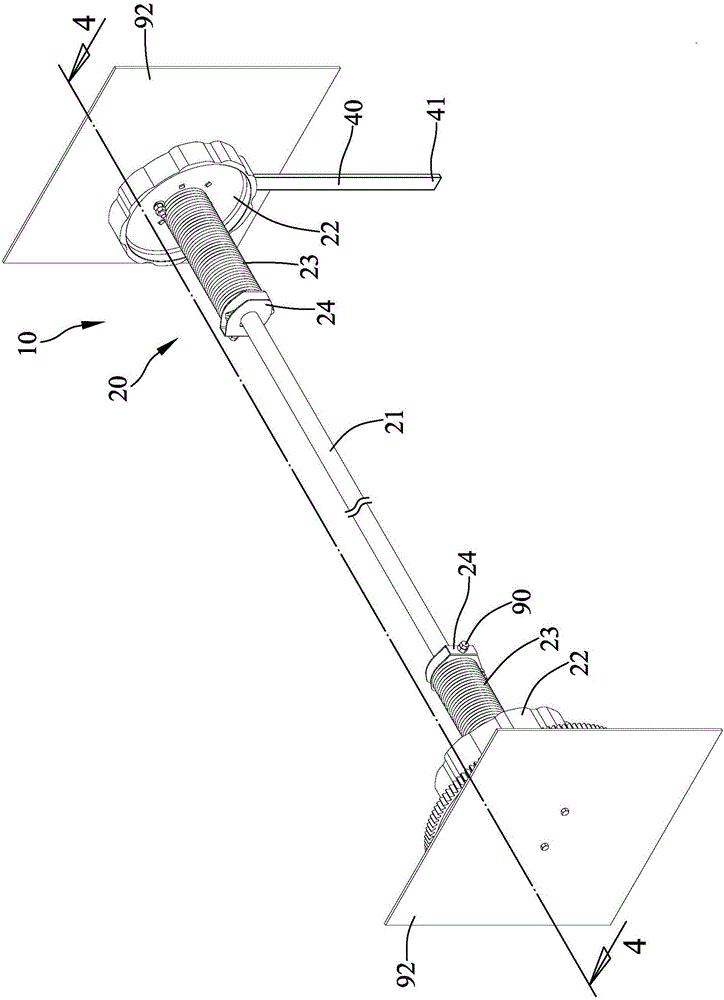

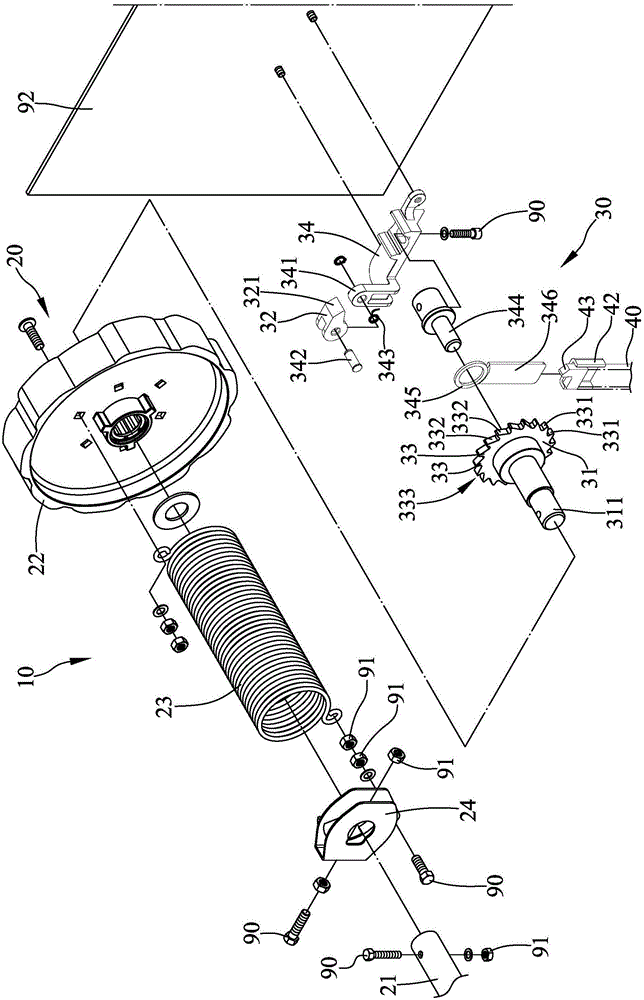

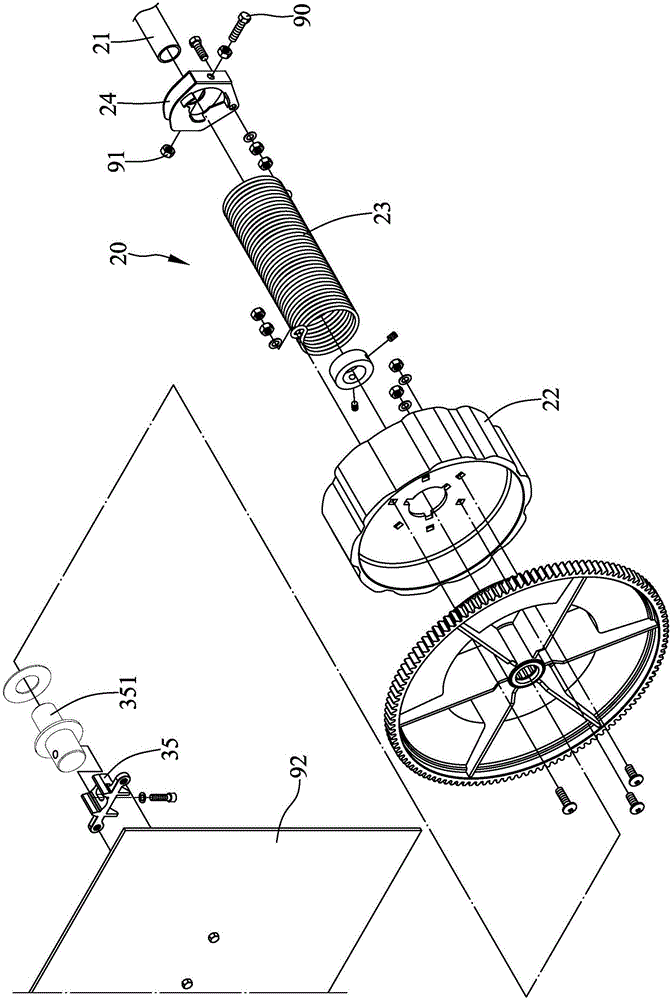

[0033] refer to Figure 1 to Figure 4 Shown is the three-dimensional appearance view, three-dimensional exploded view and cross-sectional structural view of the rolling door capable of adjusting spring torsion according to the present invention. The rolling door 10 of the present invention includes a rolling door body 20 and an adjusting device 30; wherein:

[0034]The rolling door body 20 includes a shaft 21 and two wheels 22, and the two wheels 22 are respectively rotatably sleeved on both sides of the shaft 21, so that the wheels 22 can rotate relative to the shaft. 21 spins. The rolling door body 20 also includes at least one spring 23, the number of said at least one spring 23 is two in this embodiment, one end of the spring 23 is fixed on the shaft 21, and the spring 23 is far away from the shaft One end of 21 is fixed on the wheel disc 22, and the two springs 23 are respectively connected to the two wheel discs 22 and the axle 21, and the two springs 23 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com