Air gap variant eddy speed regulating induction motor and working mode

An induction motor and variable air gap technology, which is applied to electrical components, electromechanical devices, etc., can solve problems such as increased manufacturing costs, reduced operating efficiency, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

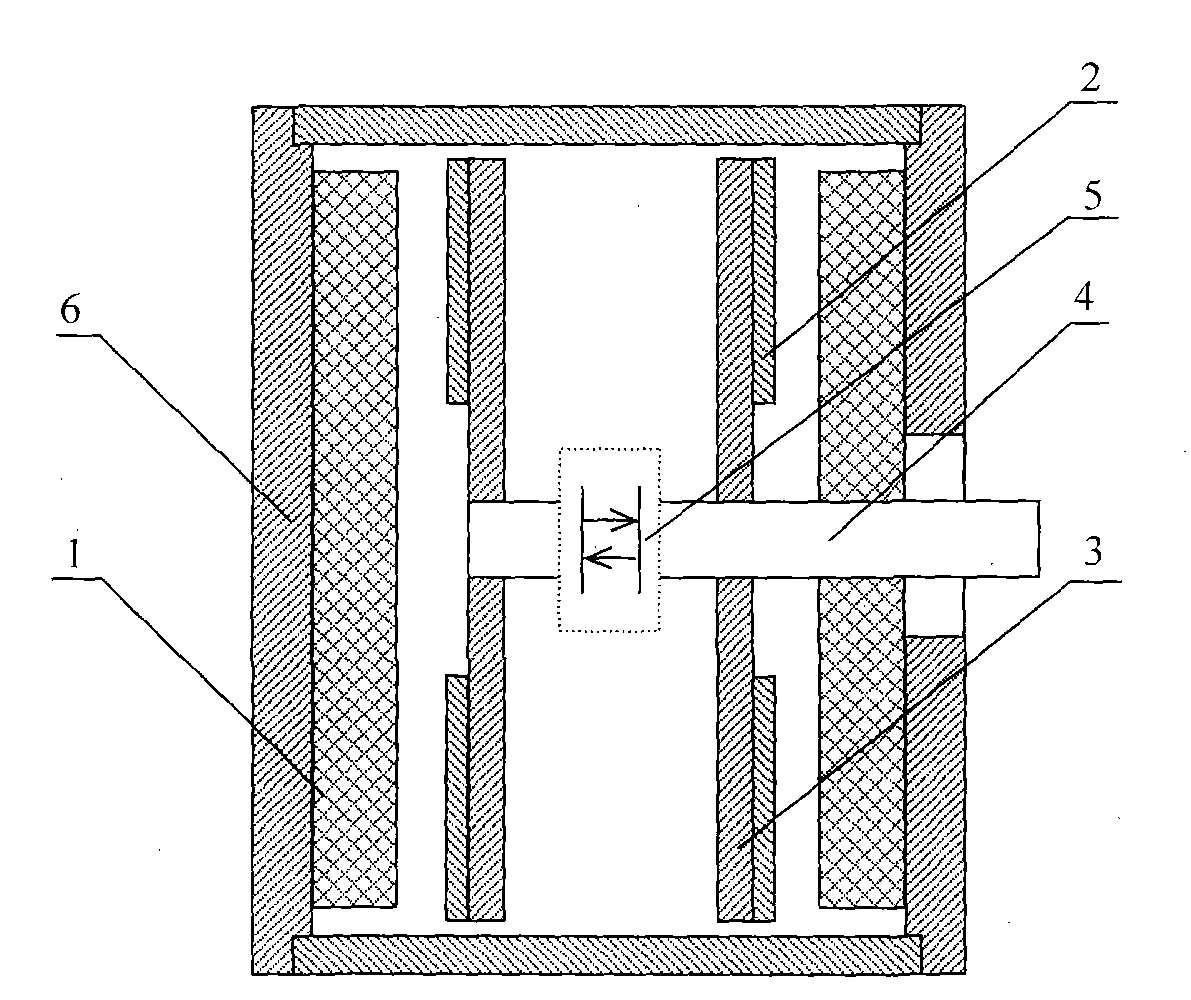

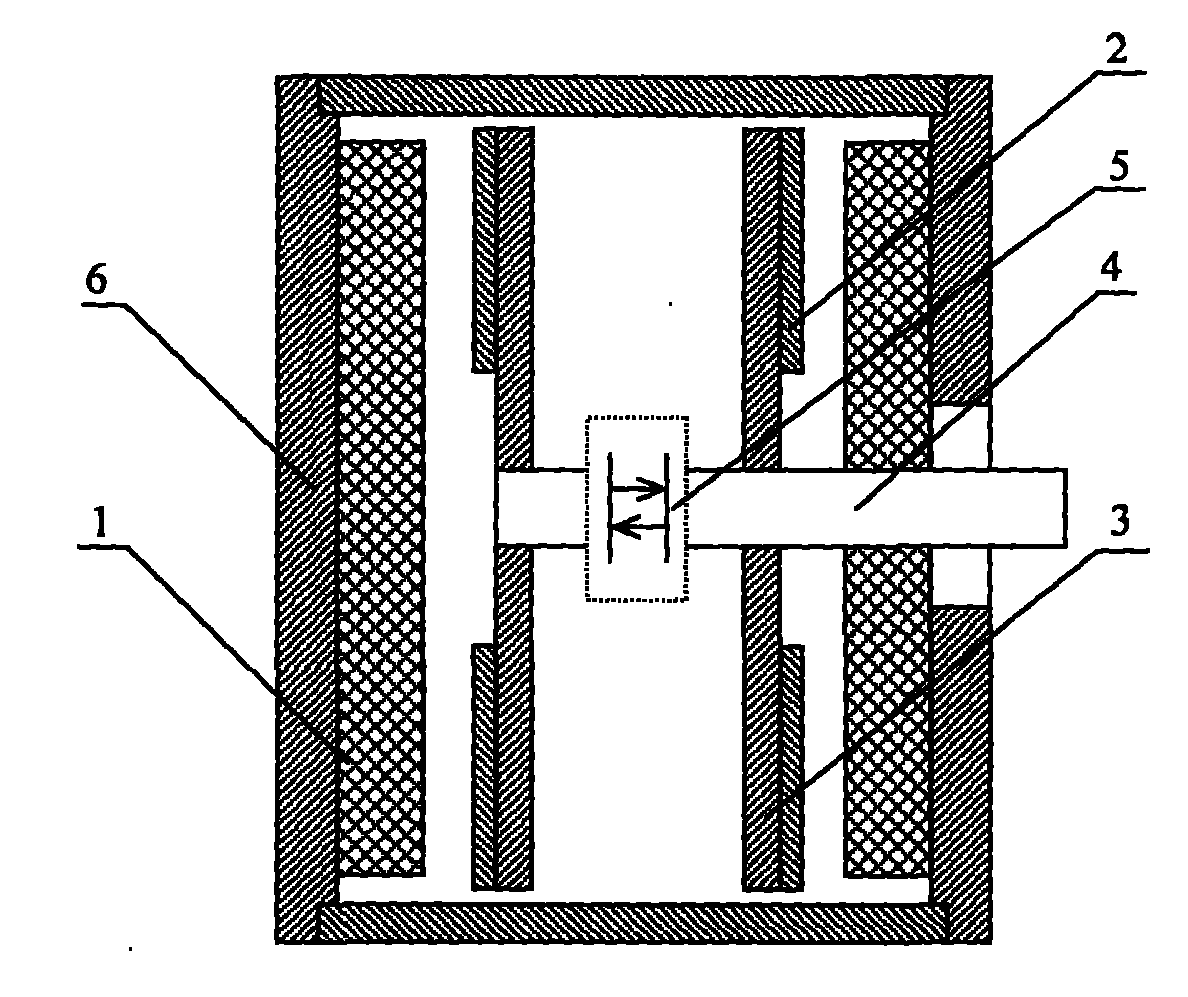

[0015] The invention adopts a special induction motor structure, that is, an air gap adjustment component is arranged between two rotors on the output shaft. The rotor of the variable air gap eddy current speed regulation induction motor has two symmetrical pieces and is fixed on the output shaft 4, and an air gap adjustment assembly 5 is arranged between the two rotors on the output shaft 4, and the rotor includes a copper disc 2, The back yoke 3 and the copper disk 2 are located outside the rotor. The output shaft 4 can change the air gap distance between the stator 1 and the copper disk 2 by adjusting the air gap adjustment assembly 5. The stator includes windings and iron cores. The iron core is fixed on the end cover 6. The iron core is in the form of a coiled iron core, and three-phase alternating current is loaded in the winding to generate a rotating magnetic field in the air gap. The output shaft 4 can change the air gap distance between the stator 1 and the copper dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com