heavy duty gearbox

A gearbox and oil supply device technology, which is applied to transmission parts, grain handling, belts/chains/gears, etc., can solve the problems of expensive, sensitive high-pressure pipelines, etc., and achieve the effect of installation space advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

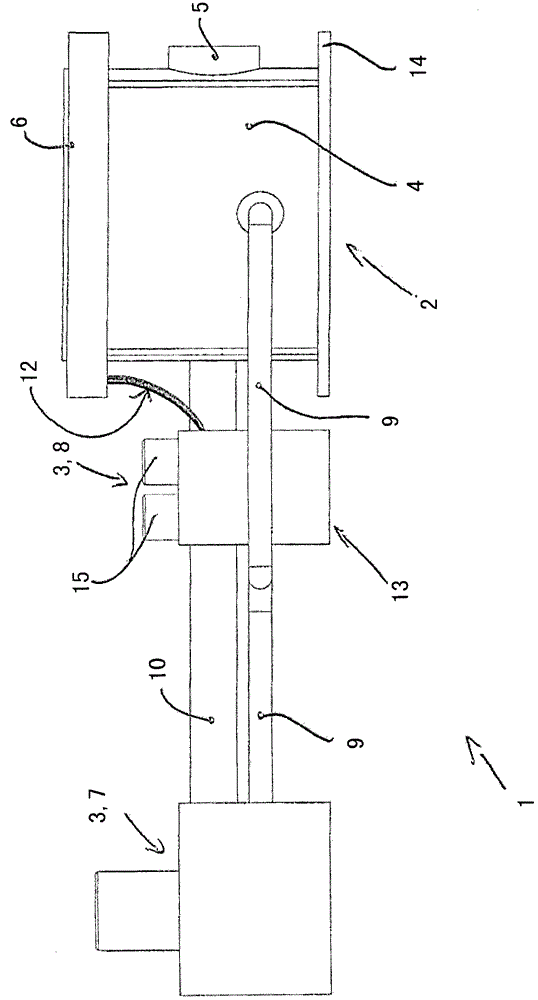

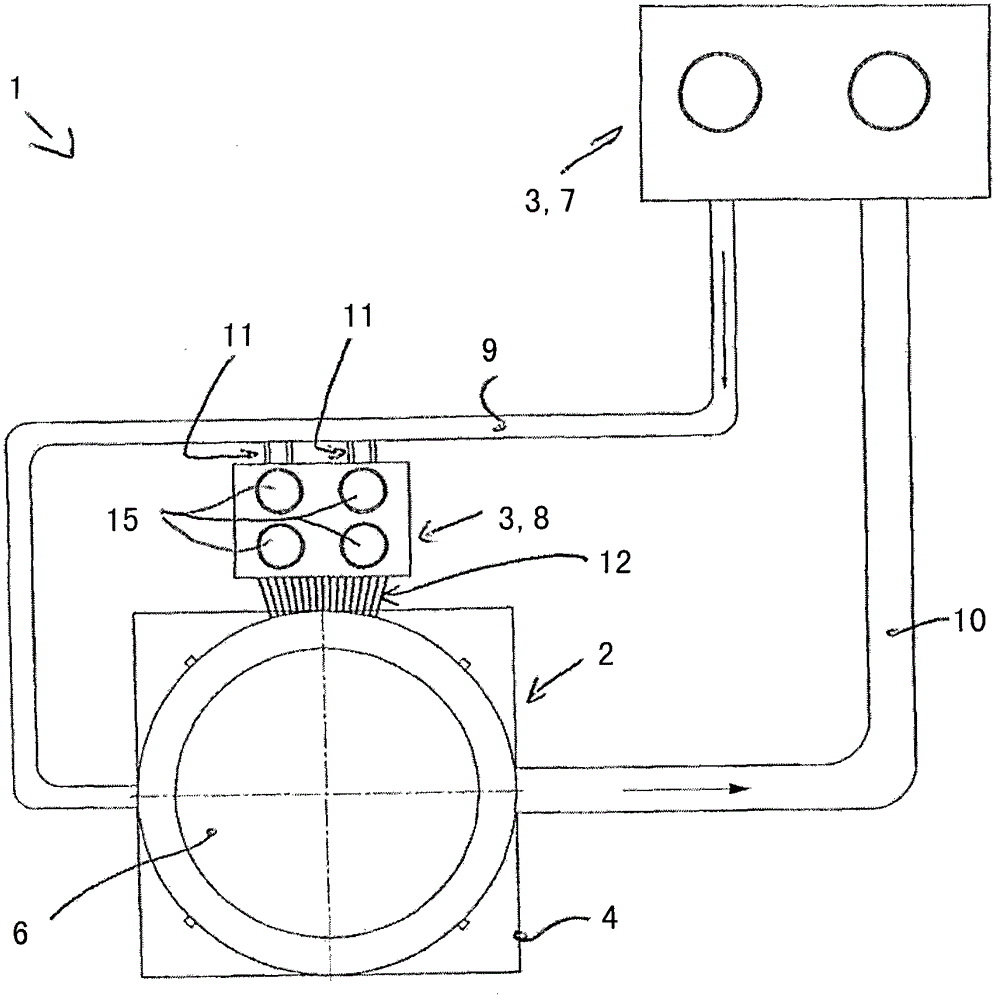

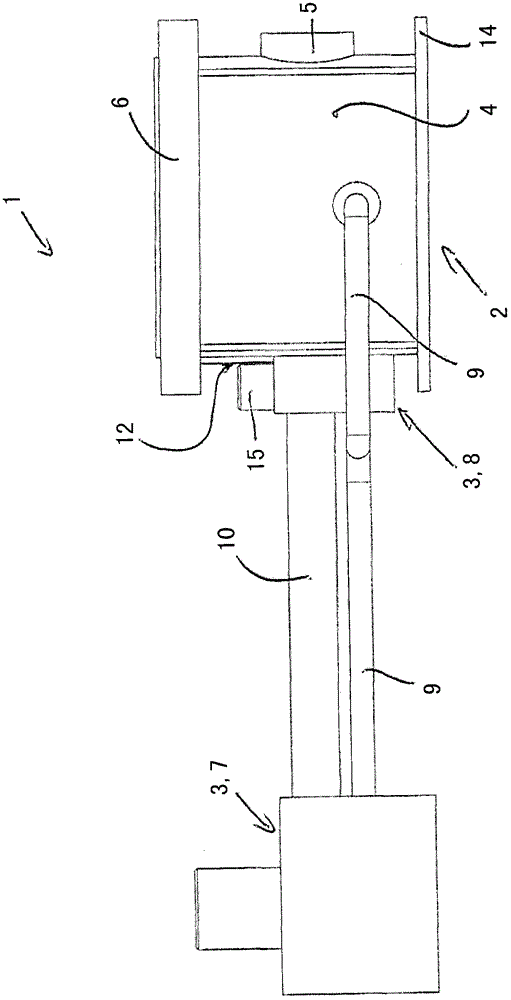

[0030] The invention relates to a heavy-duty gearbox with a gear unit and an oil supply device. The heavy-duty gearbox according to the invention is used in particular in cement mills or coal mills. In the following, refer to Figure 1 to Figure 4 The invention is described for this preferred application of a heavy duty gearbox.

[0031] However, the invention is not limited to this application and the heavy duty gearbox can actually be used in other applications as well.

[0032] figure 1 and 2 A heavy-duty gearbox 1 for use in a cement or coal mill is shown, wherein the heavy-duty gearbox 1 comprises a gear unit 2 and an oil supply 3 .

[0033] The gear unit 2 comprises a stator-side housing 4, a rotor-side input shaft 5 which can be driven by a drive motor not shown and figure 1 The invisible output shaft in the figure 1 In the exemplary embodiment, the output shaft drive is used for figure 1 The connecting flange 6 of the unit to be driven is not shown. The unit to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com