Integrated air tap joint with independent double ends

A technology of air nozzles and joint pipes, which is applied in the direction of pipes/pipe joints/pipe fittings, connections with fluid cut-off devices, passing components, etc., which can solve the problems of difficult operation, user error-prone, difficult to master, etc., to avoid operation Difficulty, even and easy application of force, and the effect of preventing serious damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation methods and specific operating procedures, but the scope of protection of the present invention is not limited to the following embodiments. .

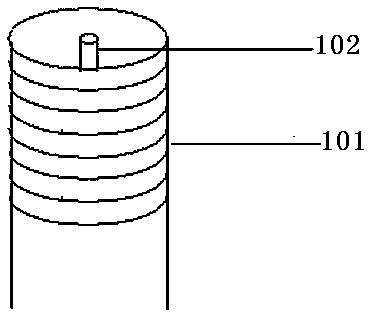

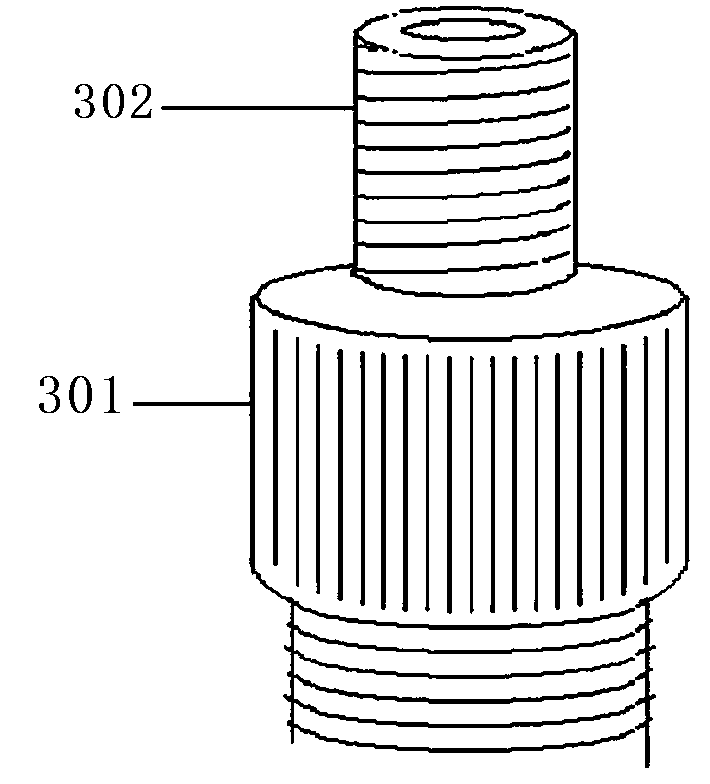

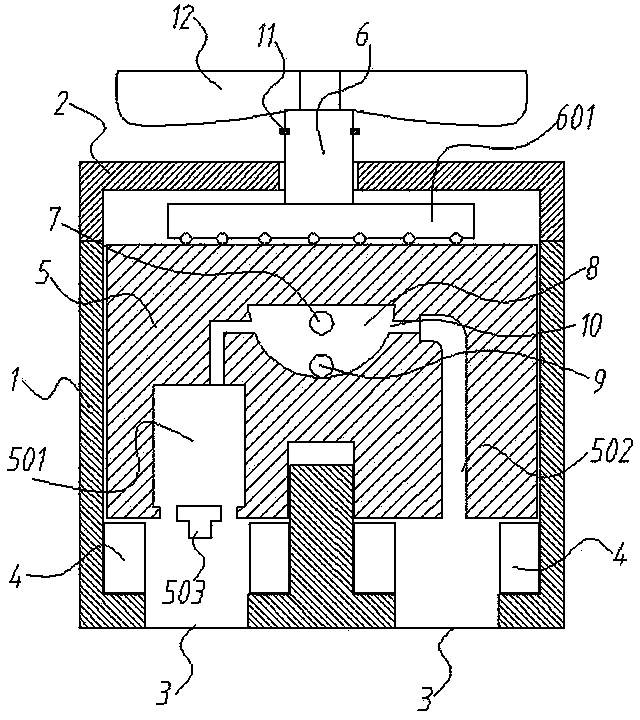

[0022] As shown in the figure, a double-ended discrete integrated gas nozzle joint includes a joint body 1 and an upper cover 2 connected to the upper end of the joint body. At the bottom of the joint body 1, there are two valves that are independent of each other and connected to the tire upper valve. The joint body bottom hole 3 matched with the mouth body corresponds to each joint body bottom hole 3. A hollow cylindrical elastic ring 4 with equal height and hollow cylindrical shape is arranged in the joint body 1, which is located on the upper part of the elastic ring 4 in the joint. The pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com