Floater valve open position testing tool and testing method

A technology of opening position and detection tool, applied in the field of measurement and testing, can solve the problems of cumbersome operation steps and difficult installation of instruments and equipment, and achieve the effect of ensuring safe flight and avoiding cumbersome operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

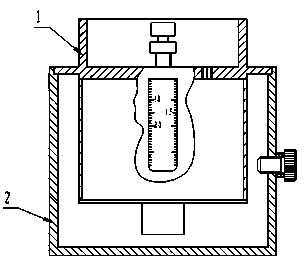

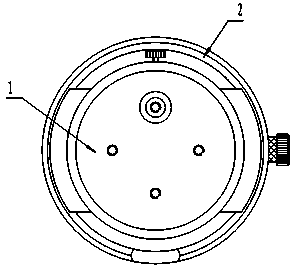

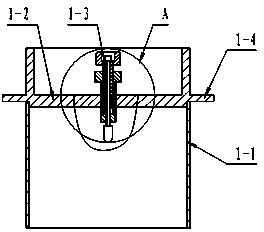

[0032] See Figure 1, figure 2 , Figure 12 , the present invention includes an upper casing 1 and a lower casing 2; the upper casing 1 is an inverted sleeve structure, and a float positioning mechanism 1-3 is arranged on the top cover 1-2 of the upper casing, and on the side of the upper casing The upper shell observation window 1-1 is set on the wall; the lower shell 2 is a cylindrical structure, and the lower shell observation window 2-1 is set on the side wall of the lower shell; the detected float valve device 3 is installed on the upper shell In the sleeve, after the upper casing 1 and the lower casing 2 are snapped together, the upper casing sleeve and the detected float valve device 3 are placed in the inner cavity of the lower casing 2, and aviation fuel is injected into the lower casing 2 to form a simulated aircraft The detection environment of the fuel tank.

[0033] see Figure 3 ~ Figure 6 , the float positioning mechanism 1-3 of the present invention includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com