System and methods for balancing mirrors in limited rotation motor systems

A technology of rotating motors and mirrors, applied in instruments, installations, optics, etc., can solve the problems of increased weight of screw groups, difficulty in perfect balance, and increased inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

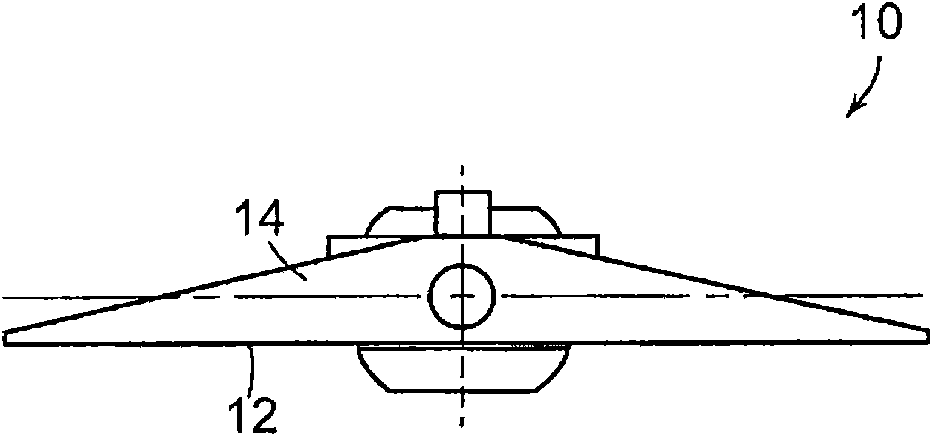

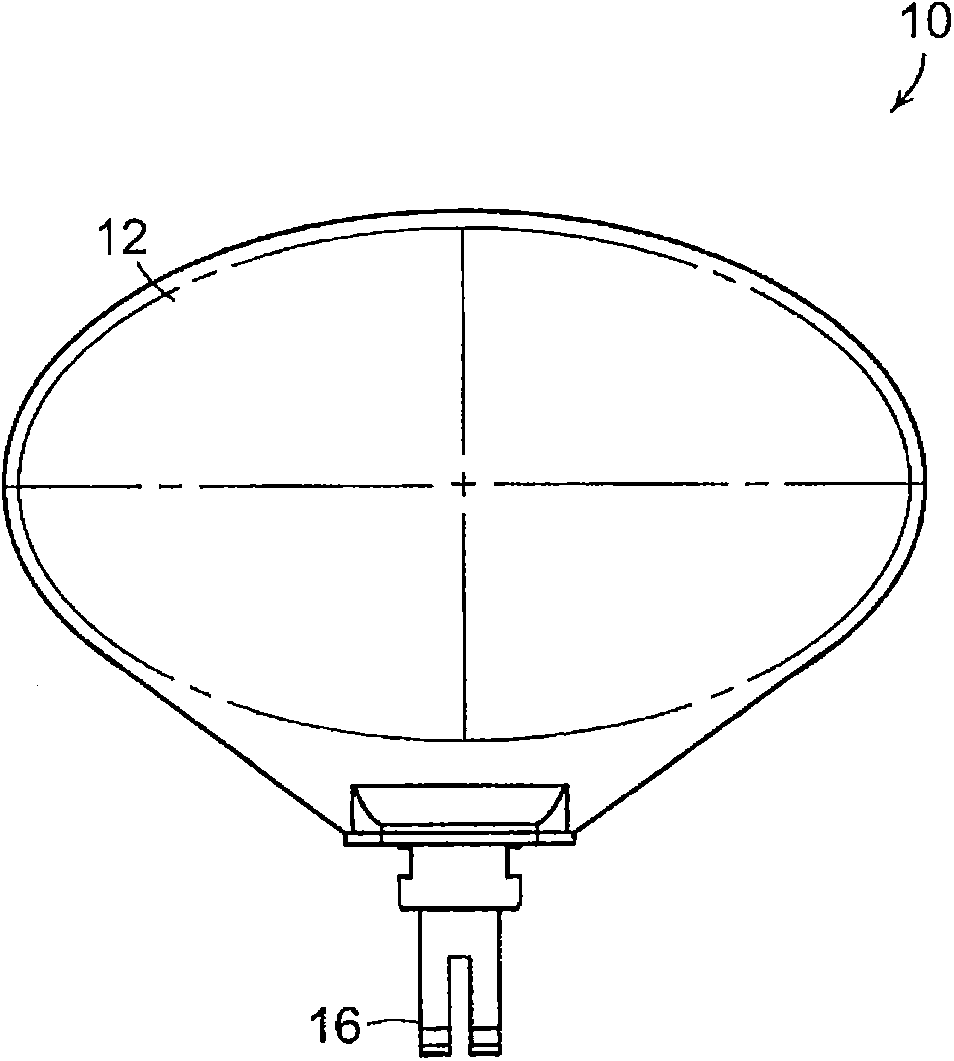

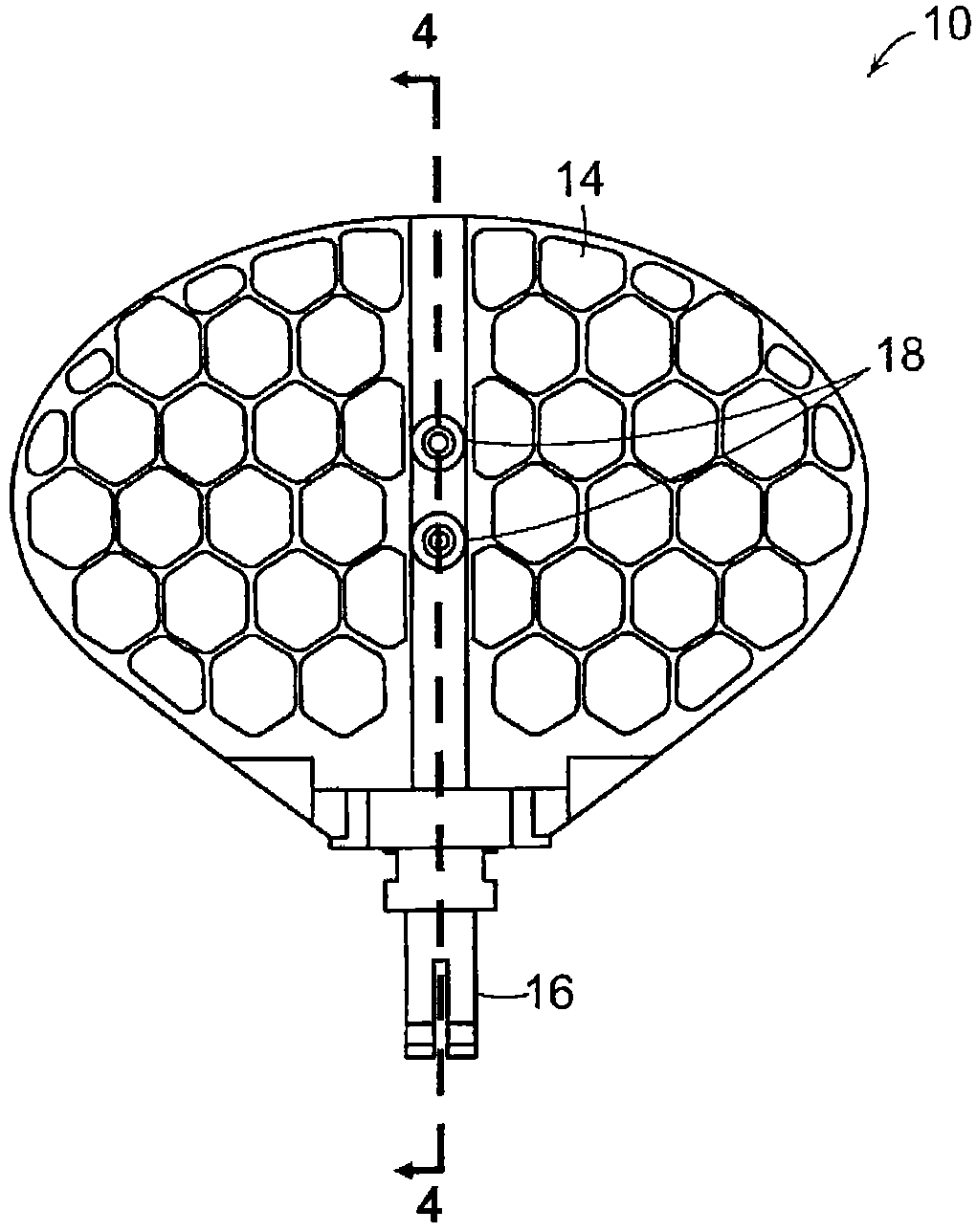

[0033] According to an embodiment, the invention firstly relates to a mirror for a limited rotation motor system, which is slightly obliquely offset in the direction of the front surface of the mirror. For front-to-back balance, one or more threaded weight screws are provided on the back of the mirror. When the weight screws are screwed all the way into the mirror (toward the front surface), the mirror remains biased towards the front, but when one or more weight screws are turned out of the mirror, a front-to-back balance point is obtained.

[0034] Side-to-side balancing is achieved using a pair of opposing weight screws with a tungsten ball locked between them. The tungsten sphere is initially positioned along the centerline of mirror rotation to minimize added inertia. After adjusting the weight screws to their respective points of balance, epoxy was applied to each screw to hold each screw in position so that each weight screw would keep still.

[0035] E.g, Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com