Double stroke mechanical latch mechanism

A mechanical and link mechanism technology, applied in the field of circuit switches and latch systems, can solve problems such as increasing reliability and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

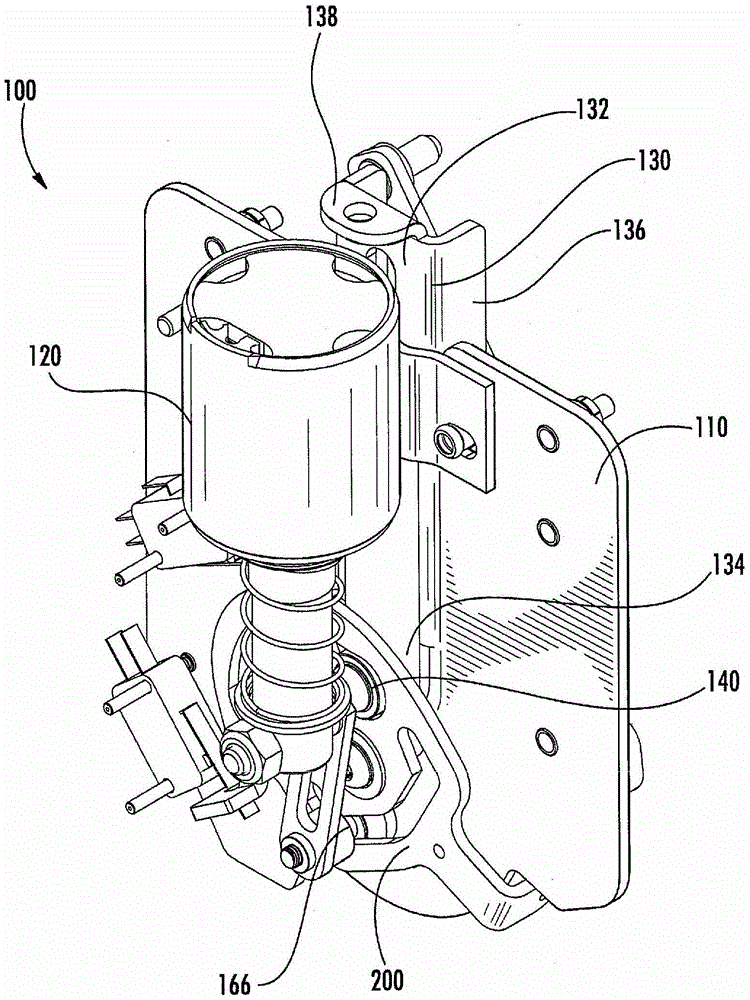

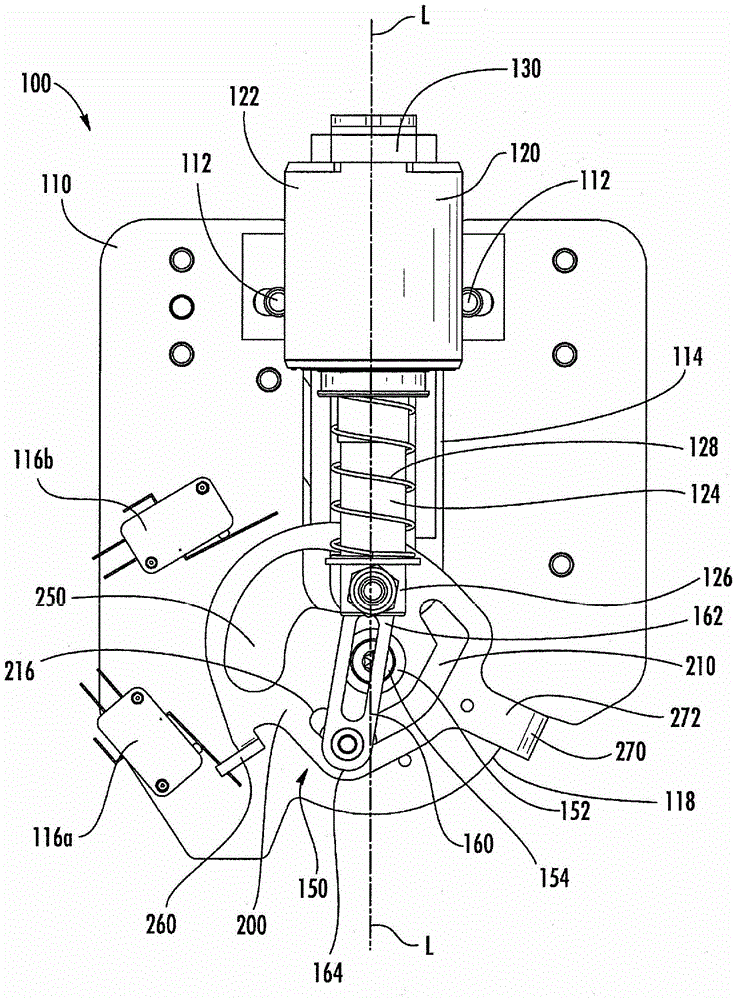

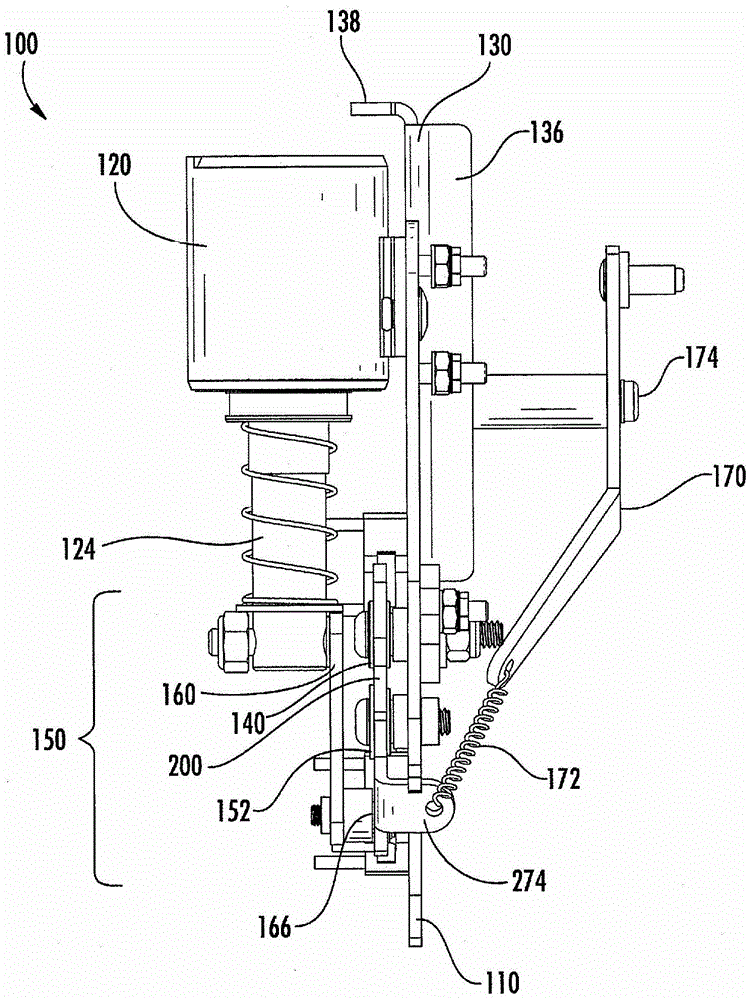

[0017] Referring generally to the figures, a latch mechanism and components thereof are shown in accordance with exemplary embodiments. A latch mechanism typically includes a solenoid, an operating lever, and a mechanical linkage (shown including a cam) coupling the solenoid to the operating lever. Actuation of the mechanical linkage causes the operating rod to move between the retracted position and the extended position. Additionally, the linkage mechanism provides a crank action. That is, each time the solenoid is actuated, it provides opposite linear motion on the operating rod. Thus, a unidirectional solenoid can be used to provide both push and pull functionality, thereby reducing cost and complexity, which in turn increases reliability.

[0018] According to an exemplary embodiment, a latch system may be used as a vacuum interrupter based medium voltage capacitor switch. In this embodiment, the lever may be configured to selectively couple at least two electrical con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com