Fin and flat tube press-fitting device for heat exchanger core integrated unit

A technology integrating unit and forming device, applied in the field of fin processing, can solve the problems of high production labor cost, low production efficiency, and product quality affected by human factors, and achieve the effect of solving low production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

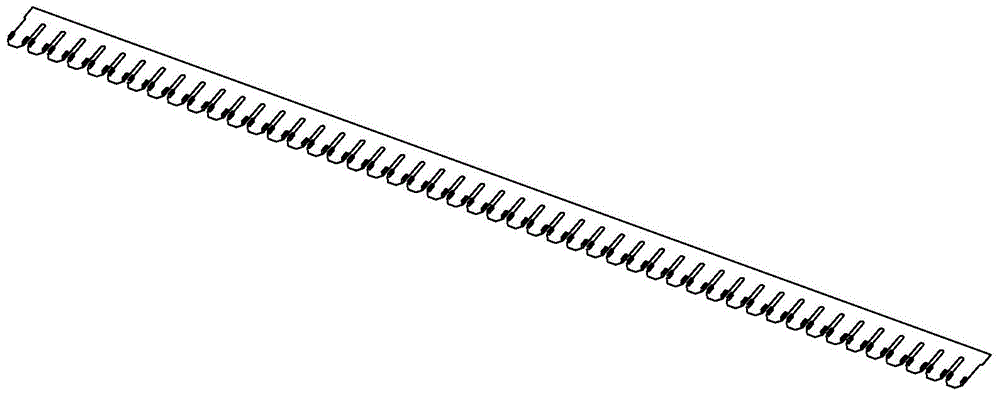

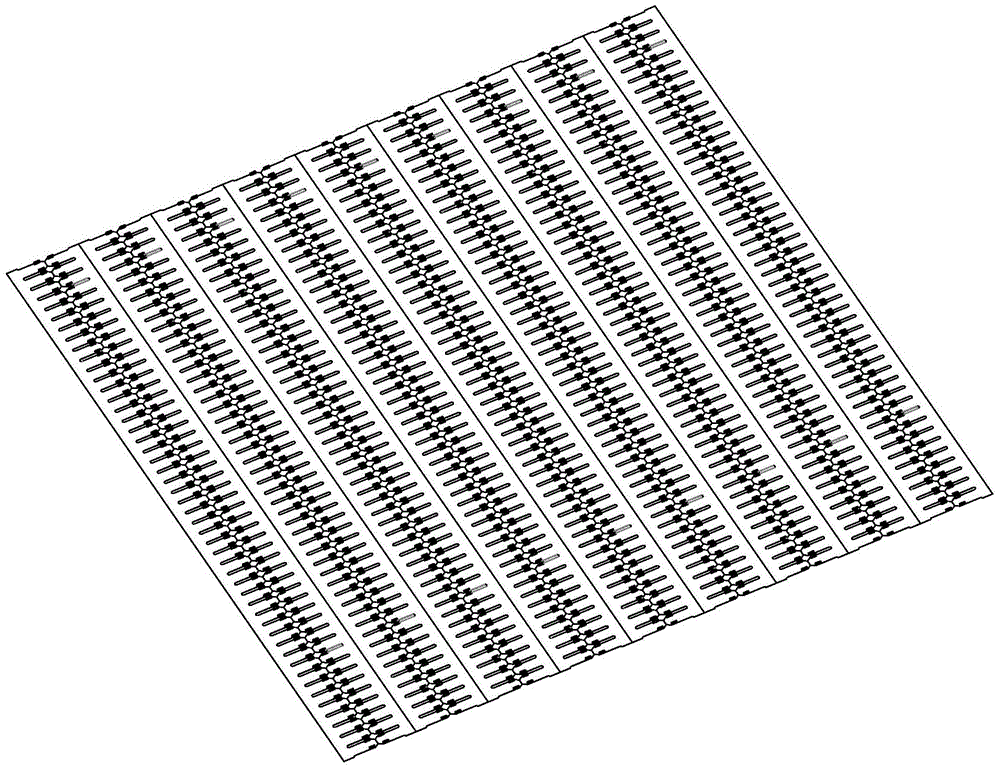

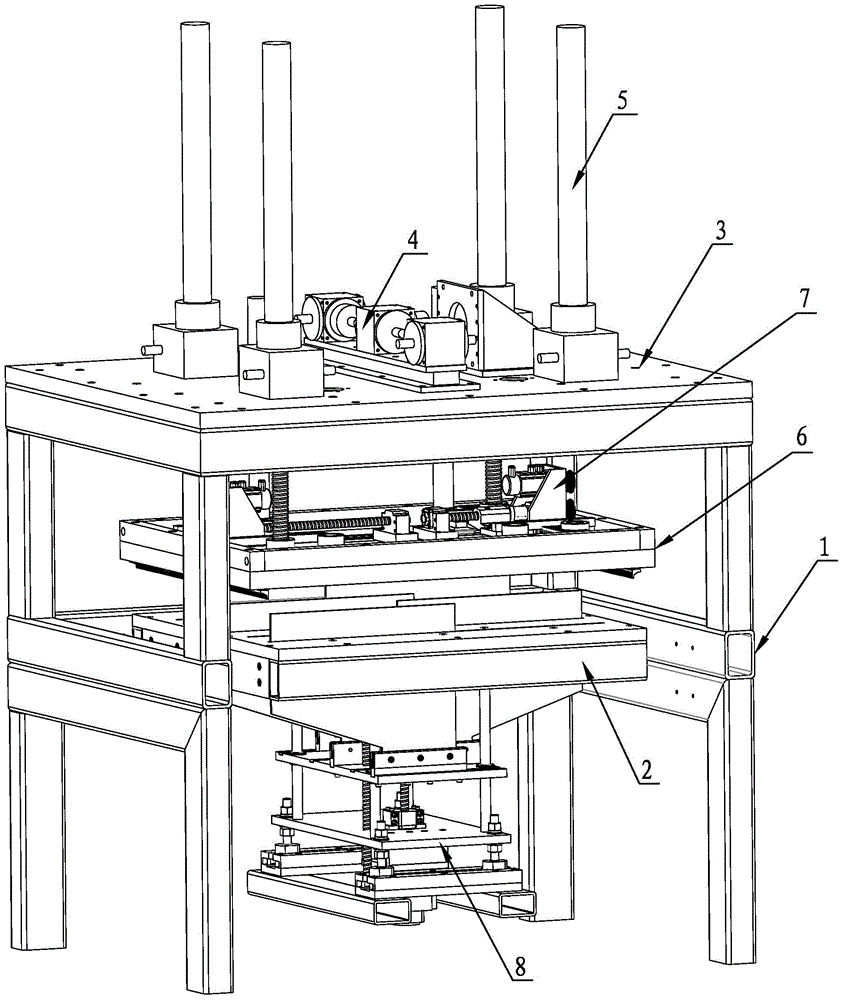

[0032] A fin and flat tube press-fit molding device for a heat exchanger core integrated unit, such as Figure 3-12 As shown, it includes a fixed frame 1, a worktable 2, an upper fixed plate 3, a synchronous drive steering gear group 4, an upper lifting screw 5, a lifting pressure plate 6, two sets of linearly distributed fin tightening mechanisms 7 and a roof lifting mechanism 8 , the worktable 2 and the upper fixed plate 3 are fixedly connected with the fixed frame 1 as a whole, the worktable 2 is located below the upper fixed plate 3, and is arranged in the fixed frame 1, and the synchronous drive steering gear group 4 includes a center Steering gear 41, side steering gear 42 and output steering gear 43, the worm gear in the output steering gear 43 is screwed with the upper lifting screw 5 through the threaded hole in the center, the central steering gear 41 is driven by a motor, and the two side steering gears 42 are symmetrical The two side diverters 42 are synchronously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com