Lifting method under the condition of shield structure of shield machine

A technology for enclosure structures and shield machines, which is applied in mining equipment, earthwork drilling, tunnels, etc., and can solve the problems that follow-up equipment cannot be dismantled in time, affecting the interval and the normal construction of the shield starting station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

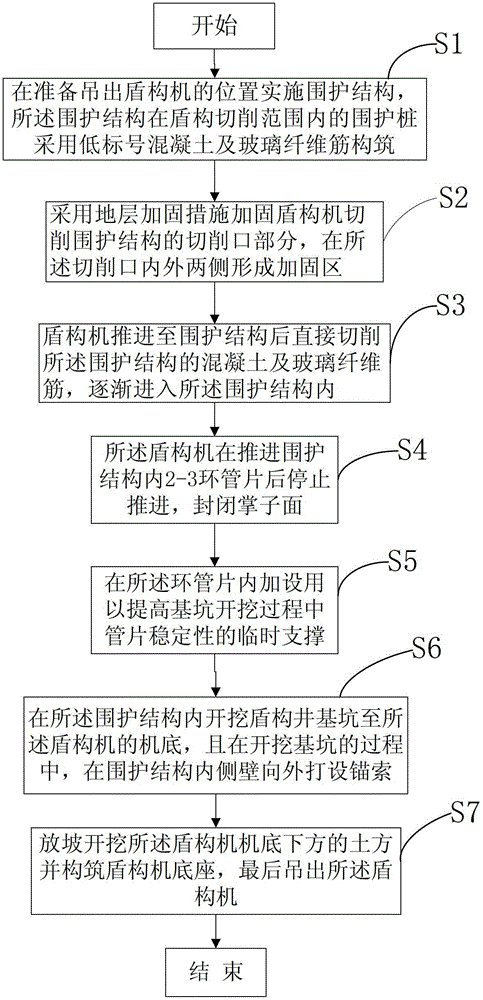

[0026] figure 1 It is a flow chart of the hoisting construction method under the condition of the enclosure structure of the shield machine in this embodiment. Such as figure 1 As shown, a method of hoisting under the condition of a shield machine enclosure structure in this embodiment includes the following steps:

[0027] Step S1, implement the enclosure structure 1 at the position where the shield machine 4 is to be hoisted out, and the enclosure piles of the enclosure structure 1 within the cutting range of the shield machine are constructed with low-grade concrete and glass fiber bars 2. Specifically, in this embodiment The low-grade concrete adopts C20 or C15 concrete.

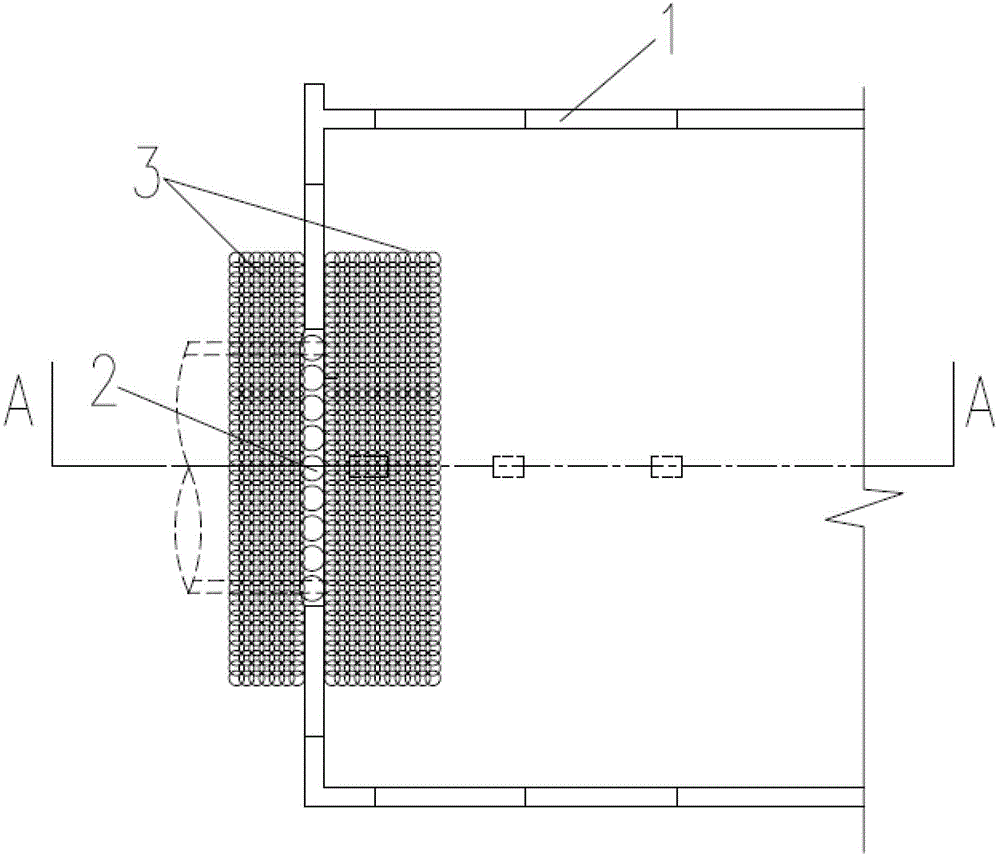

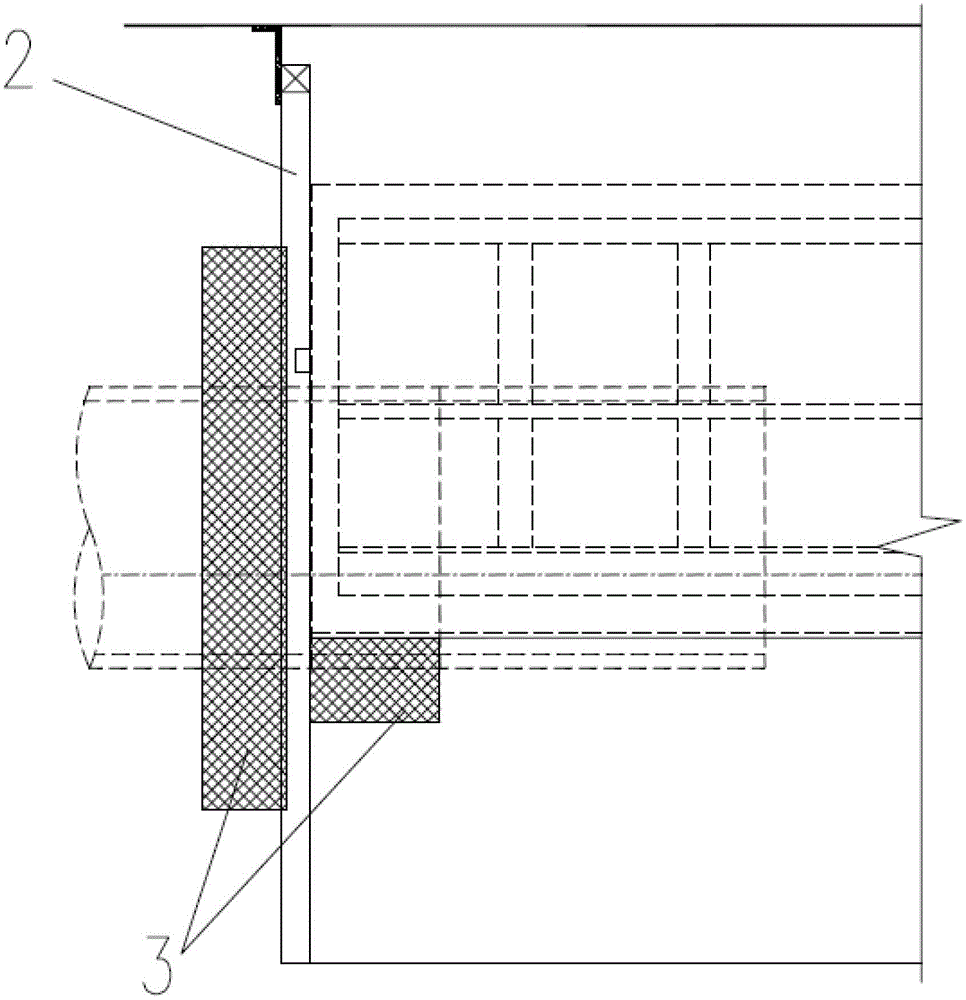

[0028] Step S2, combining figure 2 and image 3 As shown in Fig. 1, stratum reinforcement measures are adopted to reinforce the cutting opening part of the cutting enclosure structure of the shield machine, and a reinforcement area 3 is formed on both sides of the cutting opening.

[0029] Step S3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com