Rigidity-variable virtual vehicle body clamp suspension test bed

A variable stiffness, body technology, used in the field of automotive quarter suspension test benches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

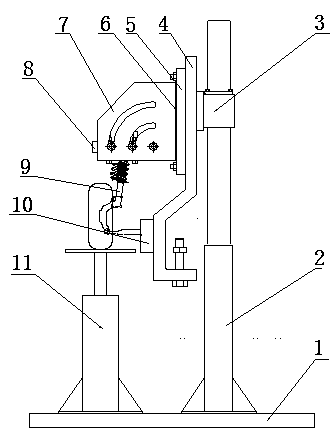

[0010] Such as figure 1 As shown, a suspension test bench with a variable stiffness virtual body fixture includes a T-shaped groove bottom plate 1, a sliding guide column 2, a sliding bearing and a sliding bearing seat 3, a virtual body component, a suspension and a wheel component 9, and an excitation table 11 .

[0011] 1) Install the sliding guide column 2 and the vibration excitation table 11 on both ends of the T-shaped groove bottom plate 1, fix them with T-shaped bolts, and adjust the suspension and wheel assembly 9 by changing the distance between the sliding guide column 2 and the vibration excitation table 11 installation size. The suspension and wheel assembly 9 are placed on the vibration table 11 and connected with the virtual body assembly. The virtual body assembly is installed on the sliding guide column 2 through the sliding bearing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com