a stamping machine

A technology of punching machine and punching mechanism, applied in the field of punching machine, can solve problems such as punching die stuck, achieve the effect of high automation level, reduce labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described further below:

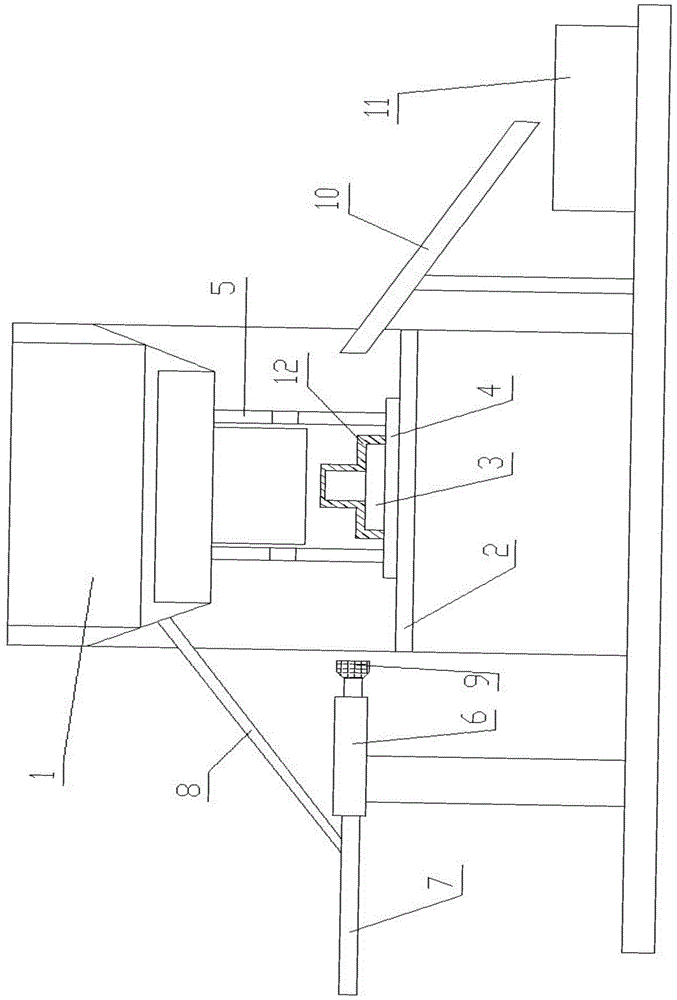

[0024] combine figure 1 : A stamping machine, comprising a stamping mechanism 1, a workbench 2, a punch 3, a partition 4, a telescopic rod 5, a chute 6, a slide bar 7, a connecting rod 8, a trough 10, a storage box 11, and a punch 3 is placed on the surface of the workbench 2, and the separator 4 is set on the outside of the punch 3, so as not to interfere with the normal operation of the stamping mechanism 1. One end of the telescopic rod 5 is connected to the partition 4, and the other end is connected to the stamping mechanism 1. The maximum expansion and contraction of the telescopic rod 5 The length value is not greater than the maximum value of the vertical height from the connection between the telescopic rod 5 and the stamping mechanism 1 to the upper surface of the punch 3; when the stamping mechanism 1 rises to the highest position, the partition 4 should drive the workpiece 12 to leave the punch 3, and The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com