A stamping device for easy demoulding

A stamping device and demoulding technology, which is applied in the field of stamping machinery, can solve problems such as being stuck on the mold and not being resolved, and achieve the effects of simple structure, high automation level, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

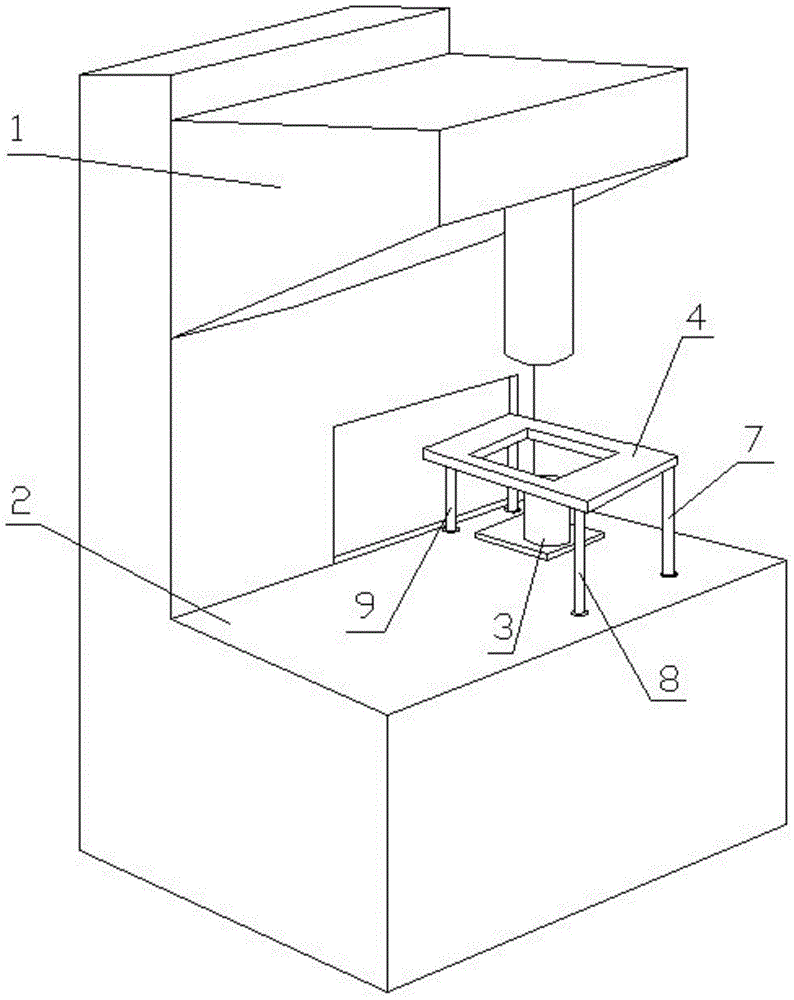

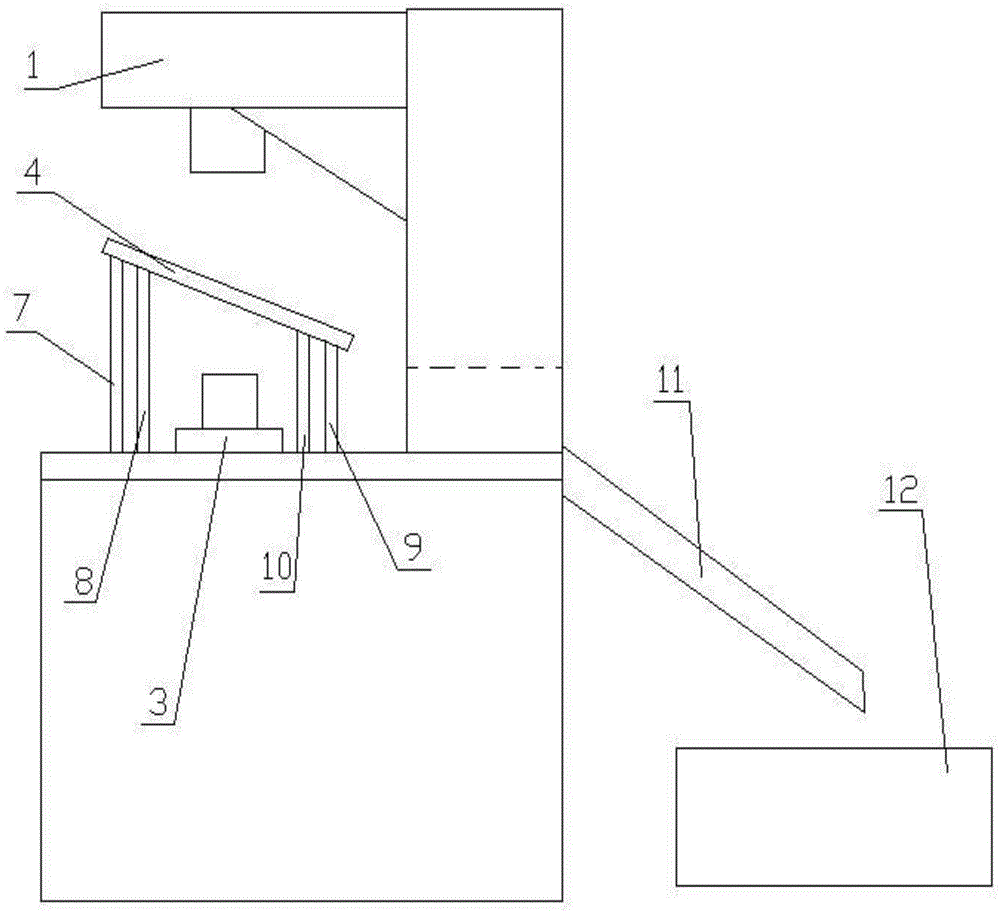

[0028] to combine figure 1 , figure 2 : A stamping device that is convenient for demoulding, including a stamping mechanism 1, a workbench 2, a punch 3, a trough 11, a storage box 12, a partition 4, a driving device, the punch 3 is placed on the surface of the workbench 2, and the partition The plate 4 is set on the outside of the punch 3, and the driving device includes 4 cylinders, namely the third cylinder 7, the fourth cylinder 8, the fifth cylinder 9, and the sixth cylinder 10, which are symmetrical with respect to the punch 3, and are sequentially connected with the partition plate 4. The bottom is connected, the telescopic heights of the third and fourth cylinders are greater than those of the fifth and sixth cylinders, and the driving device is electrically connected with the stamping mechanism 1 .

[0029] After the stamping operation of the impact mechanism 1 is finished, the stamping mechanism 1 rises. At this time, the driving device receives a signal, and the cy...

Embodiment 2

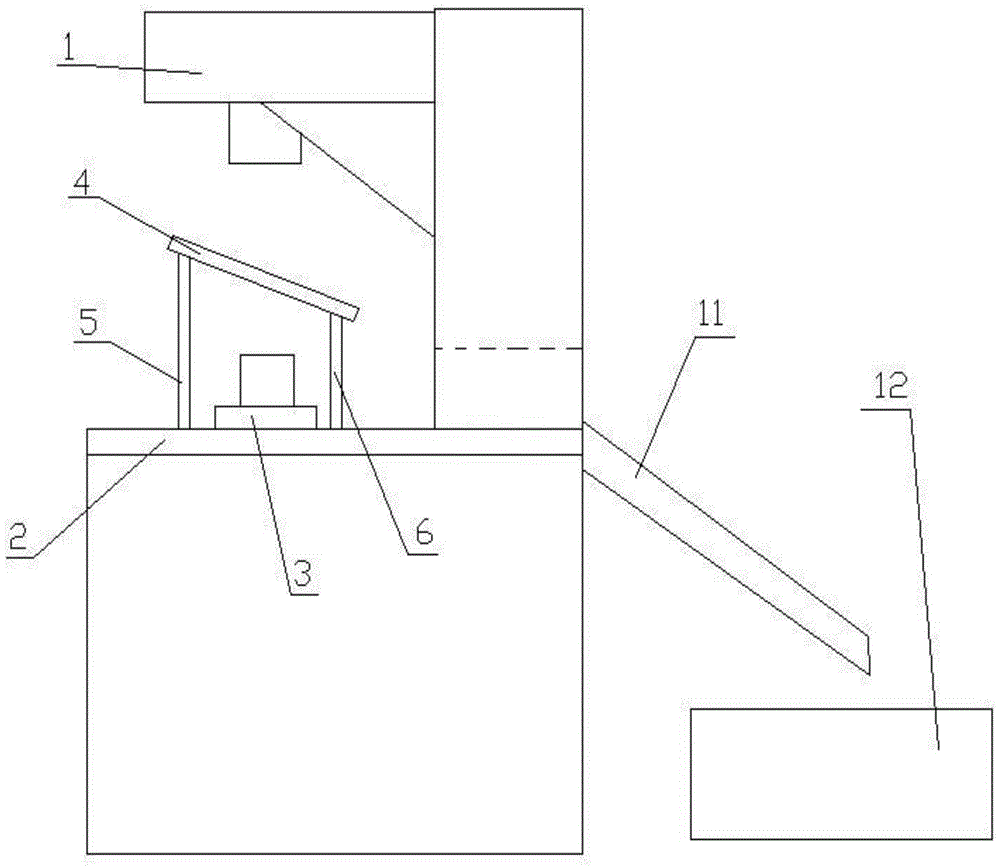

[0035] to combine image 3 : A stamping device that is convenient for demoulding, including a stamping mechanism 1, a workbench 2, a punch 3, a trough 11, a material storage box 12, a partition 4, a driving device, the punch 3 is placed on the surface of the workbench 2, and the partition The plate 4 is set on the outside of the punch 3, and the driving device includes two cylinders, that is, the first cylinder 5 and the second cylinder 6, which are located on both sides of the punch 3. The first and second cylinders are connected to the bottom of the partition 4, and the second cylinder The telescopic height of the first air cylinder 5 is greater than that of the second air cylinder 6 , and the driving device is electrically connected with the stamping mechanism 1 .

[0036] After the stamping operation of the impact mechanism 1 is finished, the stamping mechanism 1 rises. At this time, the driving device receives a signal, and the cylinder drives the partition 4 to rise. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com