A Toolpath Generation Method for Surface Finishing Based on Solver of Traveling Salesman Problem

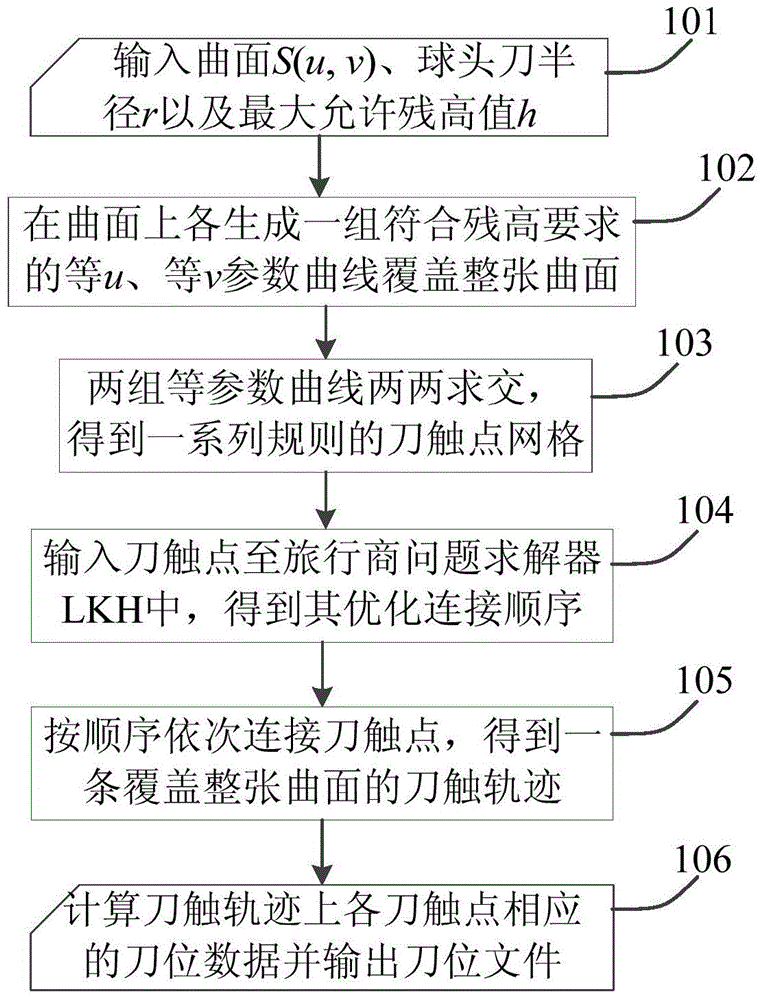

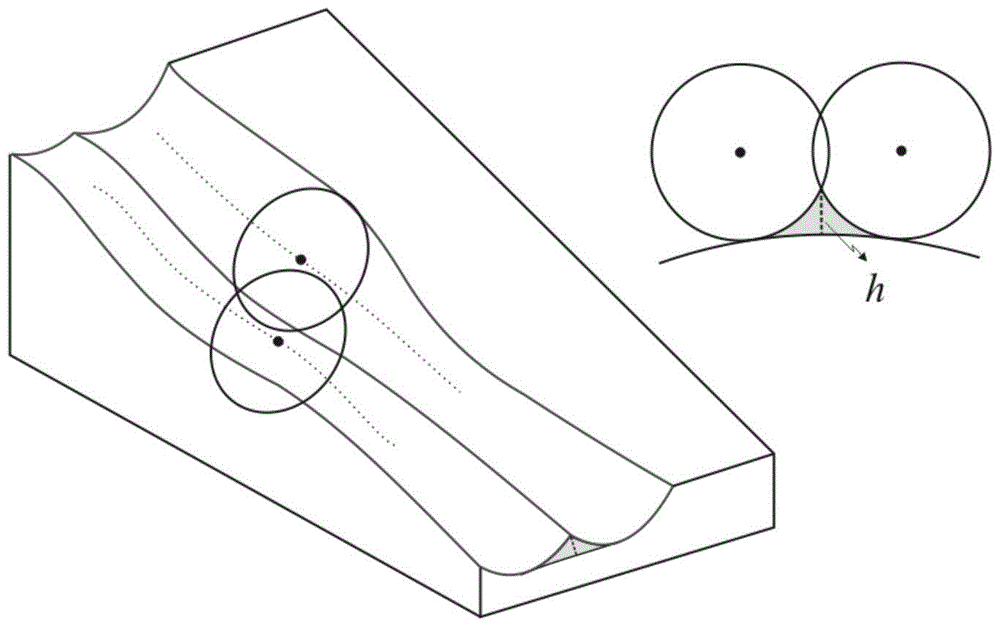

A traveling salesman problem and solver technology, applied in data processing applications, prediction, calculation, etc., can solve problems such as path length optimization, and achieve the effect of improving surface finishing efficiency, reducing the number of knife lifts, and shortening the total length of the path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Two typical implementation examples of the present invention are as follows:

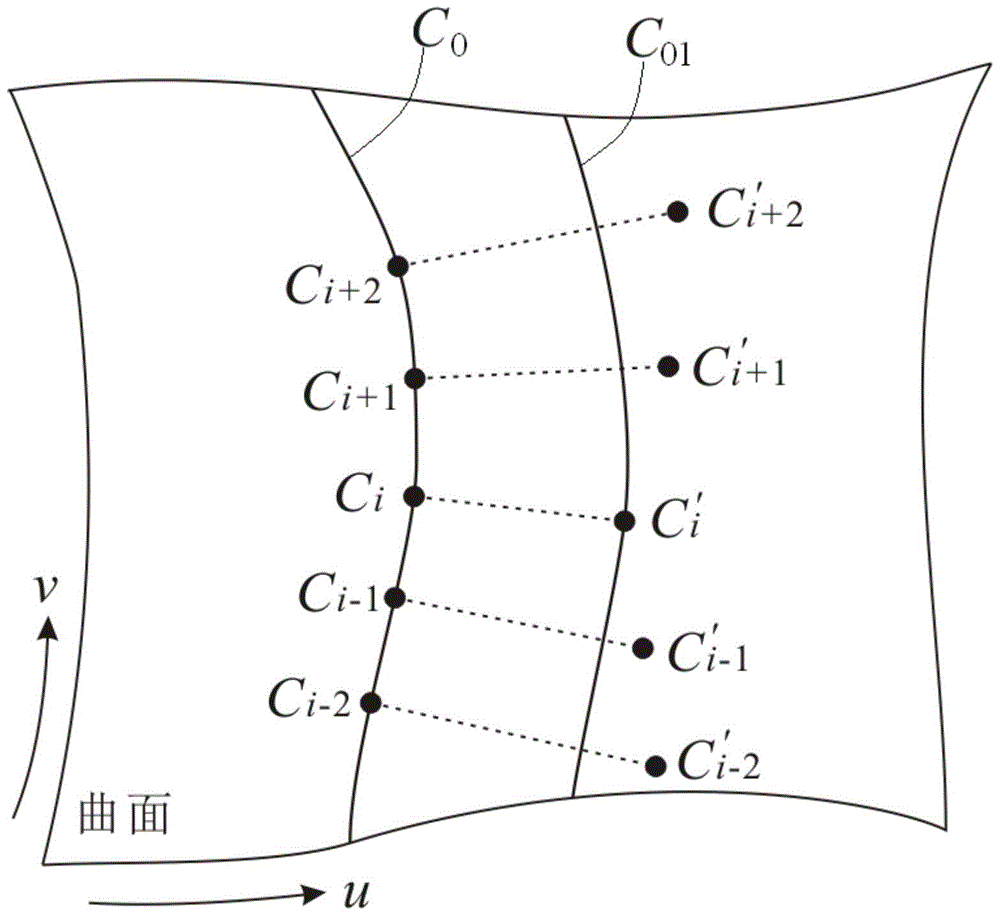

[0098] 1. The free-form surface of the part to be machined selected in the first example is as follows: Image 6 As shown in a, the special feature of this surface is that its v0 boundary curve (about 110mm long) is much longer than its v1 boundary curve (about 36mm long). The radius of the selected ball nose cutter is r=5mm, and the maximum allowable residual height value is h=0.1mm.

[0099] Image 6 b shows the grid of regular knife contacts generated according to step 103 of the present invention. Depend on Image 6 b, it can be seen that due to the special characteristics of the curved surface, the distribution of knife contacts is relatively uniform in the v direction; while in the u direction, the distribution of knife contacts at the end of the curve near v0 is relatively sparse, and the distribution of knife contacts at the end of the curve near v1 is relatively dense. Image 6 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com